Base paper refers to the raw, uncoated material used as the foundation for various paper products, whereas finished paper has undergone additional processes like coating, calendering, or printing to enhance its appearance, texture, and functionality. Understanding the differences between base paper and finished paper helps you select the right type for specific applications such as packaging, printing, or labeling.

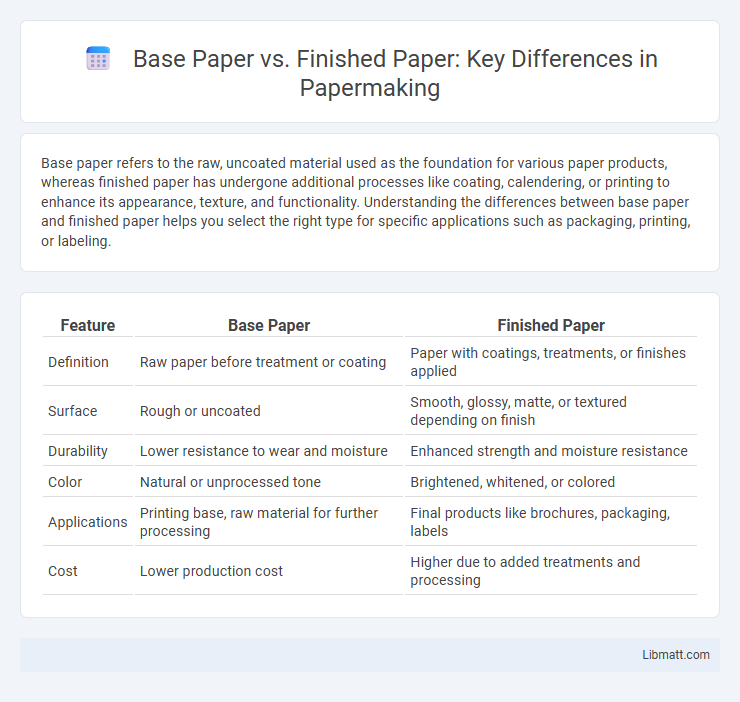

Table of Comparison

| Feature | Base Paper | Finished Paper |

|---|---|---|

| Definition | Raw paper before treatment or coating | Paper with coatings, treatments, or finishes applied |

| Surface | Rough or uncoated | Smooth, glossy, matte, or textured depending on finish |

| Durability | Lower resistance to wear and moisture | Enhanced strength and moisture resistance |

| Color | Natural or unprocessed tone | Brightened, whitened, or colored |

| Applications | Printing base, raw material for further processing | Final products like brochures, packaging, labels |

| Cost | Lower production cost | Higher due to added treatments and processing |

Introduction to Base Paper and Finished Paper

Base paper serves as the foundational substrate in papermaking, characterized by its raw, untreated state designed for further processing or coating. Finished paper undergoes additional treatments such as calendaring, coating, or surface sizing to enhance properties like smoothness, brightness, and durability, tailored for specific end-uses. The transformation from base paper to finished paper significantly influences print quality, coating adhesion, and the overall performance of the final product.

Defining Base Paper: Key Characteristics

Base paper serves as the foundational substrate in paper manufacturing, characterized by its uniform thickness, smooth surface, and controlled porosity, designed to provide strength and durability. It typically lacks coatings or finishes, allowing it to be versatile for further processing such as printing, coating, or laminating. The key attributes of base paper include high tensile strength, consistent fiber distribution, and appropriate moisture content to ensure stability during finishing processes.

What is Finished Paper?

Finished paper refers to base paper that has undergone various surface treatments and coatings to enhance its appearance, texture, durability, and printability. It includes processes such as calendaring, coating, embossing, and sizing to meet specific performance and aesthetic requirements for end-use applications. Your choice between base paper and finished paper depends on the desired quality and functional characteristics of the final product.

The Manufacturing Process: From Base to Finished Paper

The manufacturing process begins with base paper, which is produced on a paper machine by forming, pressing, and drying fibers into a continuous sheet. Finished paper involves additional steps such as coating, calendering, and surface treatments that enhance properties like smoothness, brightness, and printing quality. Your choice between base and finished paper depends on the specific application requirements and desired performance characteristics.

Material Composition Differences

Base paper primarily consists of uncoated cellulose fibers that provide strength and flexibility, allowing for further processing or coating. Finished paper contains additional coatings or treatments such as clay, calcium carbonate, or polymers, which enhance surface smoothness, brightness, and printability. These material composition differences directly affect the durability, appearance, and application suitability of the paper products.

Surface Treatments and Coatings

Base paper serves as the foundational substrate that undergoes various surface treatments and coatings to enhance its properties for specific applications. Surface treatments such as calendering and sizing improve smoothness, gloss, and printability, while coatings add functional layers including clay or polymer to optimize opacity, brightness, and durability. Your choice between base paper and finished paper depends on the required surface characteristics tailored through these advanced treatment processes.

Functional Applications: Base Paper vs Finished Paper

Base paper serves as the foundational substrate primarily used for printing, coating, and laminating processes that enhance its properties. Finished paper boasts functional applications such as improved surface smoothness, durability, and specialized coatings for water resistance, gloss, or print quality. These enhancements enable finished paper to meet specific requirements in packaging, labeling, and high-end printing industries.

Quality Control and Standards

Base paper undergoes rigorous quality control measures, including tests for thickness, strength, and surface smoothness, ensuring it meets industry standards before further processing. Finished paper is subjected to additional inspections for coating uniformity, brightness, and printability to guarantee final product consistency and performance. Adhering to ISO and TAPPI standards throughout both stages ensures optimal material quality and customer satisfaction.

Cost and Economic Considerations

Base paper generally has a lower production cost due to its simpler manufacturing process and fewer finishing treatments, making it a cost-effective option for bulk applications. Finished paper involves additional processing steps such as coating, embossing, or surface treatments, which increase both material and labor expenses, reflecting in higher market prices. Your choice between base and finished paper should consider the balance between budget constraints and the required quality or functionality for your specific use.

Choosing Between Base Paper and Finished Paper

Choosing between base paper and finished paper depends on the specific requirements of the end product and cost-efficiency. Base paper, often uncoated and untreated, provides a versatile and economical option for further processing such as coating, printing, or lamination, while finished paper comes pre-treated, offering enhanced surface properties like gloss, texture, or durability ready for immediate use. Evaluating factors such as production cost, desired appearance, and application helps optimize material selection for packaging, printing, or specialty paper products.

base paper vs finished paper Infographic

libmatt.com

libmatt.com