Uncoated woodfree paper offers a natural, matte finish that enhances ink absorption and provides a smooth writing surface, ideal for DIY projects or printing needs requiring a more organic feel. Coated woodfree paper features a glossy or satin surface that improves image sharpness and color vibrancy, making it perfect for high-quality brochures, magazines, and professional presentations where visual impact matters.

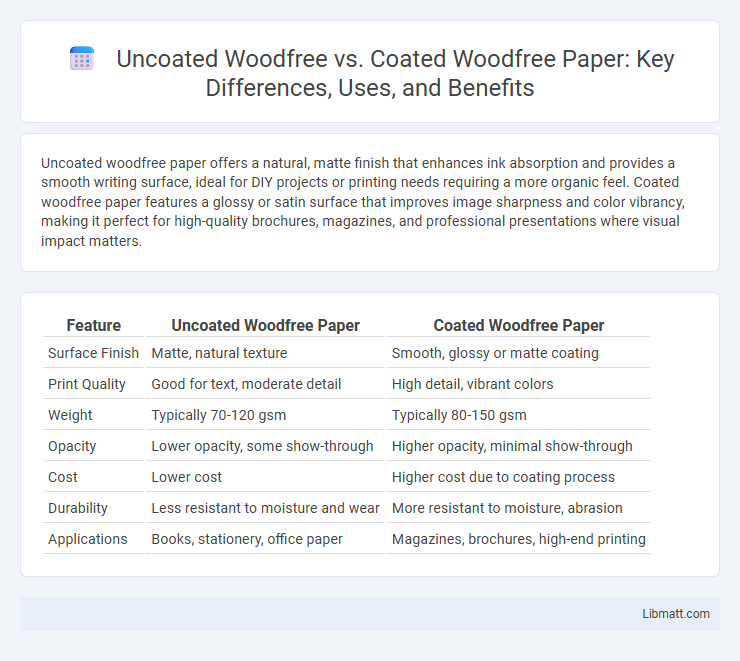

Table of Comparison

| Feature | Uncoated Woodfree Paper | Coated Woodfree Paper |

|---|---|---|

| Surface Finish | Matte, natural texture | Smooth, glossy or matte coating |

| Print Quality | Good for text, moderate detail | High detail, vibrant colors |

| Weight | Typically 70-120 gsm | Typically 80-150 gsm |

| Opacity | Lower opacity, some show-through | Higher opacity, minimal show-through |

| Cost | Lower cost | Higher cost due to coating process |

| Durability | Less resistant to moisture and wear | More resistant to moisture, abrasion |

| Applications | Books, stationery, office paper | Magazines, brochures, high-end printing |

Understanding Uncoated Woodfree Paper

Uncoated woodfree paper is made from chemically processed pulp that is free from mechanical fibers, resulting in a smooth, natural surface without any coating. This paper type offers excellent printability and absorbs ink effectively, making it ideal for books, stationery, and everyday printing needs. Understanding uncoated woodfree paper helps you choose the right material for projects requiring a tactile, matte finish with superior readability and durability.

What is Coated Woodfree Paper?

Coated woodfree paper features a smooth surface achieved by applying a layer of coating materials such as clay or calcium carbonate, enhancing its brightness, opacity, and printability. This coating improves image sharpness and color vibrancy, making it ideal for high-quality magazines, brochures, and advertising materials. Compared to uncoated woodfree paper, coated woodfree offers superior surface smoothness and reduced ink absorption for sharper and more vivid printed results.

Key Differences Between Uncoated and Coated Woodfree Papers

Uncoated woodfree paper offers a natural, porous surface ideal for writing and easy ink absorption, while coated woodfree paper features a smooth, sealed surface that enhances print clarity and color vibrancy. The coating adds a barrier that improves durability and reduces ink bleed, making it suitable for high-quality printing and photography. Your choice depends on whether you prioritize tactile feel and ink absorption or sharp print detail and surface protection.

Print Quality Comparison: Uncoated vs Coated Woodfree

Coated woodfree paper offers superior print quality with sharper images and more vibrant colors due to its smooth, sealed surface that prevents ink absorption. Uncoated woodfree paper provides a softer, more natural finish but may result in less crisp print details and muted colors because of its porous texture. Choosing coated woodfree paper enhances your printed materials with better resolution and color accuracy, ideal for high-quality graphics and photos.

Applications and Uses of Uncoated Woodfree Paper

Uncoated woodfree paper is widely used in applications requiring excellent printability and a natural, tactile feel, such as letterheads, business forms, and books. Its porous surface allows for superior ink absorption, making it ideal for high-quality printing in office stationery, brochures, and flyers. This paper type is preferred for documents that benefit from easy writing and reduced glare, including notebooks and manuals.

Applications and Uses of Coated Woodfree Paper

Coated woodfree paper is widely used in high-quality printing applications such as magazines, brochures, catalogs, and advertising materials due to its smooth surface and enhanced printability. The coating allows for vibrant color reproduction and sharp image details, making it ideal for marketing collateral and professional publications. Its durability and resistance to smudging also make it suitable for packaging and labels requiring a polished, premium finish.

Environmental Impact: Uncoated vs Coated Woodfree

Uncoated woodfree paper generally has a lower environmental impact than coated woodfree paper due to its simpler production process, which requires fewer chemicals and less energy. The absence of coatings, often composed of clay, calcium carbonate, or synthetic polymers, reduces the difficulty of recycling uncoated woodfree paper and minimizes landfill waste. Consequently, uncoated woodfree supports more sustainable forestry practices and better biodegradability compared to its coated counterpart.

Cost Considerations and Budgeting

Uncoated woodfree paper generally costs less than coated woodfree due to simpler manufacturing processes and lower material usage, making it a budget-friendly choice for bulk printing. Coated woodfree paper involves additional coating layers that increase production expenses, resulting in higher prices suited for premium projects requiring enhanced print quality and durability. Budget planning should consider the trade-off between cost efficiency with uncoated options and the quality benefits of coated paper to align with specific project goals.

Factors to Consider When Choosing Paper Type

Selecting between uncoated woodfree and coated woodfree paper depends on print quality, ink absorption, and intended use; coated woodfree offers a smooth surface ideal for sharp images and vibrant colors, while uncoated woodfree provides a natural texture better for readability and writing. Consider factors such as finish preference, durability, and production costs, as coated paper tends to be more resistant to wear but is also typically more expensive. Environmental impact and recyclability may also influence the choice, with uncoated woodfree paper often being more eco-friendly due to fewer chemical treatments.

Conclusion: Selecting the Right Woodfree Paper for Your Needs

Uncoated woodfree paper offers a natural texture and excellent printability, making it ideal for everyday printing and writing tasks where a matte finish is preferred. Coated woodfree paper provides a smooth surface with enhanced brightness and sharper image reproduction, suitable for high-quality brochures, magazines, and marketing materials. Choosing between uncoated and coated woodfree paper depends on your project's aesthetic requirements, printing method, and budget considerations to achieve optimal results.

uncoated woodfree vs coated woodfree Infographic

libmatt.com

libmatt.com