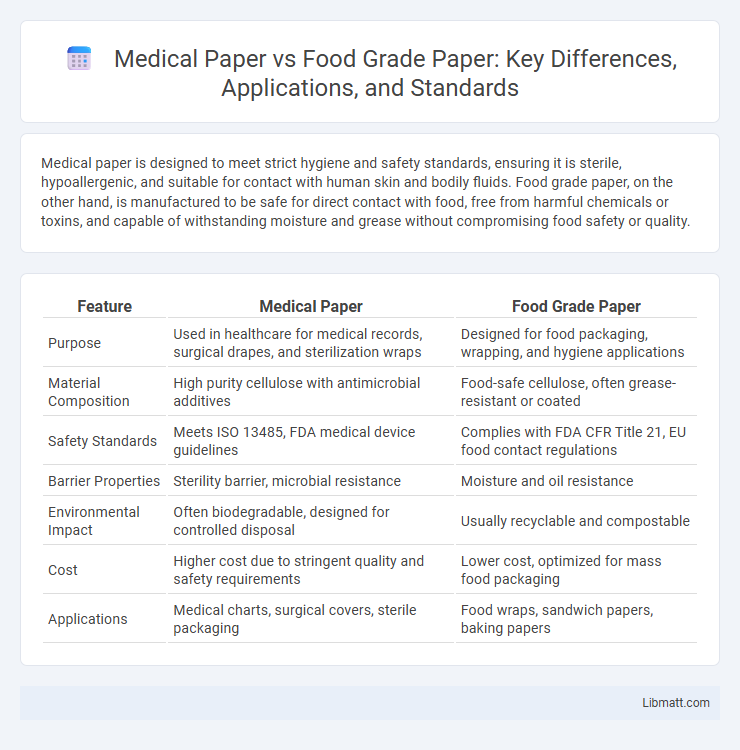

Medical paper is designed to meet strict hygiene and safety standards, ensuring it is sterile, hypoallergenic, and suitable for contact with human skin and bodily fluids. Food grade paper, on the other hand, is manufactured to be safe for direct contact with food, free from harmful chemicals or toxins, and capable of withstanding moisture and grease without compromising food safety or quality.

Table of Comparison

| Feature | Medical Paper | Food Grade Paper |

|---|---|---|

| Purpose | Used in healthcare for medical records, surgical drapes, and sterilization wraps | Designed for food packaging, wrapping, and hygiene applications |

| Material Composition | High purity cellulose with antimicrobial additives | Food-safe cellulose, often grease-resistant or coated |

| Safety Standards | Meets ISO 13485, FDA medical device guidelines | Complies with FDA CFR Title 21, EU food contact regulations |

| Barrier Properties | Sterility barrier, microbial resistance | Moisture and oil resistance |

| Environmental Impact | Often biodegradable, designed for controlled disposal | Usually recyclable and compostable |

| Cost | Higher cost due to stringent quality and safety requirements | Lower cost, optimized for mass food packaging |

| Applications | Medical charts, surgical covers, sterile packaging | Food wraps, sandwich papers, baking papers |

Definition of Medical Paper

Medical paper is a specialized type of paper designed for use in healthcare settings, characterized by its sterility, durability, and compatibility with medical devices. Unlike food grade paper, which is made to be safe for direct contact with food, medical paper must meet stringent regulatory standards to prevent contamination and ensure patient safety. Your choice of paper should prioritize these critical attributes when used in medical applications.

Definition of Food Grade Paper

Food grade paper is a type of paper specifically manufactured to meet safety standards for direct contact with food, ensuring it is free from harmful chemicals and contaminants. It complies with regulatory guidelines established by organizations such as the FDA or EFSA to prevent substance migration that could affect food safety. You can rely on food grade paper for packaging, wrapping, or serving food without compromising hygiene or quality.

Key Differences Between Medical and Food Grade Paper

Medical paper is engineered to meet strict sterility and barrier requirements, protecting wounds and medical instruments from contamination, while food grade paper prioritizes food safety by being non-toxic, grease-resistant, and compliant with FDA food contact regulations. The composition of medical paper often includes additives for antimicrobial properties and durability under sterilization methods like autoclaving, unlike food grade paper which is designed to prevent oil and moisture seepage during food packaging and preservation. Your choice between these papers should depend on the specific needs for hygiene, safety standards, and functional requirements in medical or food-related environments.

Common Applications of Medical Paper

Medical paper is specially designed for applications requiring sterile environments, such as surgical drapes, sterilization wraps, and medical packaging, where barrier properties against bacteria and viruses are critical. Unlike food grade paper, which prioritizes safety for food contact and grease resistance, medical paper must meet stringent regulatory standards for biocompatibility and microbial barrier efficiency. Your choice of medical paper ensures the integrity of sterile instruments and reduces the risk of contamination in healthcare settings.

Typical Uses for Food Grade Paper

Food grade paper is primarily used for packaging and wrapping food items to ensure safety and prevent contamination during storage and transportation. It is commonly found in fast food wrappers, bakery bags, sandwich wraps, and candy packaging, all designed to meet strict regulatory standards for food contact materials. This type of paper facilitates hygiene, preserves freshness, and complies with food safety regulations such as FDA and EU standards.

Safety and Regulatory Standards

Medical paper adheres to stringent safety and regulatory standards set by agencies such as the FDA and ISO to ensure biocompatibility, sterility, and resistance to contamination. Food grade paper complies with food safety regulations including FDA CFR Title 21 and EU food contact materials legislation, designed to prevent chemical migration and contamination during food packaging. Both types of paper undergo rigorous testing for specific applications to maintain health and safety standards unique to medical and food industries.

Material Composition and Manufacturing Processes

Medical paper is primarily composed of high-purity cellulose fibers free from contaminants, processed under sterile conditions to meet strict regulatory standards for biocompatibility and hygiene. Food grade paper utilizes cellulose fibers treated with food-safe adhesives and coatings, ensuring safety without compromising recyclability or compostability. Manufacturing medical paper involves rigorous sterilization and quality control protocols, whereas food grade paper production emphasizes compliance with food contact regulations and resistance to grease and moisture.

Sterilization and Hygiene Requirements

Medical paper undergoes stringent sterilization processes such as autoclaving and gamma radiation to ensure complete microbial elimination, meeting rigorous hygiene standards for surgical and clinical environments. Food grade paper is manufactured under strict sanitary conditions to prevent contamination but typically does not require sterilization, as its primary function is safe contact with food rather than sterility. The distinction in sterilization and hygiene requirements reflects the higher risk tolerance in medical applications compared to food packaging.

Packaging and Storage Considerations

Medical paper is manufactured to meet stringent sterility and barrier requirements, ensuring protection against contaminants and maintaining product integrity during packaging and storage. Food grade paper emphasizes moisture resistance and contamination prevention to safely contain edible products, complying with FDA regulations for direct food contact. Both types necessitate controlled storage environments to preserve their specialized properties and ensure safety during distribution and use.

Choosing the Right Paper for Industry Needs

Medical paper offers superior sterility, biocompatibility, and regulatory compliance essential for healthcare applications, while food grade paper ensures safety from contaminants and meets strict FDA standards for packaging edible products. Your choice depends on industry-specific requirements: medical paper supports hygiene and infection control, whereas food grade paper prioritizes food safety and preservation. Understanding these differences guides optimal material selection to meet both safety and functional demands.

medical paper vs food grade paper Infographic

libmatt.com

libmatt.com