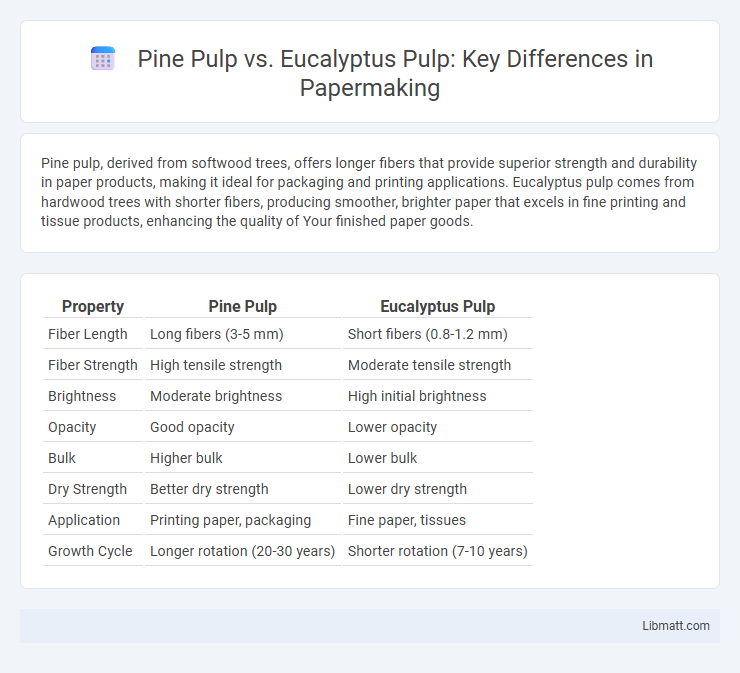

Pine pulp, derived from softwood trees, offers longer fibers that provide superior strength and durability in paper products, making it ideal for packaging and printing applications. Eucalyptus pulp comes from hardwood trees with shorter fibers, producing smoother, brighter paper that excels in fine printing and tissue products, enhancing the quality of Your finished paper goods.

Table of Comparison

| Property | Pine Pulp | Eucalyptus Pulp |

|---|---|---|

| Fiber Length | Long fibers (3-5 mm) | Short fibers (0.8-1.2 mm) |

| Fiber Strength | High tensile strength | Moderate tensile strength |

| Brightness | Moderate brightness | High initial brightness |

| Opacity | Good opacity | Lower opacity |

| Bulk | Higher bulk | Lower bulk |

| Dry Strength | Better dry strength | Lower dry strength |

| Application | Printing paper, packaging | Fine paper, tissues |

| Growth Cycle | Longer rotation (20-30 years) | Shorter rotation (7-10 years) |

Introduction to Pine Pulp and Eucalyptus Pulp

Pine pulp, derived from softwood trees like pine, is known for its longer fibers, providing higher strength and durability in paper products. Eucalyptus pulp, sourced from fast-growing hardwood trees, features shorter fibers that contribute to a smoother surface and better printability. Both pulps are widely used in the paper industry, with pine pulp typically favored for packaging and eucalyptus pulp preferred for printing and writing papers.

Botanical Differences: Pine vs Eucalyptus

Pine pulp is derived from coniferous trees in the Pinaceae family, characterized by long fibers that provide strength and durability to paper products. Eucalyptus pulp comes from fast-growing hardwood trees in the Myrtaceae family, offering shorter fibers that contribute to smoothness and softness. Understanding these botanical differences helps optimize Your paper production, balancing strength and texture based on pulp selection.

Geographic Distribution and Availability

Pine pulp is predominantly sourced from North America, Europe, and Russia, regions known for vast coniferous forests providing a steady and abundant supply. Eucalyptus pulp primarily comes from Brazil, Australia, and parts of South Africa, where fast-growing eucalyptus plantations ensure high availability and renewable harvesting cycles. Your choice between these pulps may depend on regional accessibility and sustainability practices linked to their geographic distribution.

Pulping Process Comparison

Pine pulp undergoes mechanical and chemical pulping processes, with kraft pulping being predominant due to pine's high resin content and long fibers, which enhance paper strength and durability. Eucalyptus pulp primarily uses kraft pulping combined with bleaching, benefiting from its short fibers that yield smooth, high-brightness paper ideal for printing and writing. Your choice between pine and eucalyptus pulp should consider the pulping process as it directly affects fiber quality, production efficiency, and final paper characteristics.

Fiber Characteristics and Quality

Pine pulp fibers are typically longer and coarser, providing enhanced strength and durability in paper products, making them ideal for packaging and printing papers. Eucalyptus pulp fibers are shorter and finer, resulting in smoother, softer paper with better formation and printability, commonly used in tissue and high-quality printing papers. The combination of these differing fiber characteristics influences the final quality, with pine pulp emphasizing tensile strength and eucalyptus pulp contributing to softness and opacity.

Environmental Impact Analysis

Pine pulp production typically results in higher water consumption and longer fiber growth cycles, influencing its environmental footprint compared to eucalyptus pulp, which grows faster and requires less water. Eucalyptus pulp's rapid growth and efficiency contribute to lower carbon emissions and reduced land use, making it a more sustainable option in many regions. Your choice between pine and eucalyptus pulp can significantly affect environmental outcomes, particularly in water usage and carbon sequestration capacities.

Cost Efficiency and Market Value

Pine pulp generally offers greater cost efficiency due to its higher fiber yield and lower production expenses, making it a preferred choice for large-scale paper manufacturing. Eucalyptus pulp, though often more expensive, commands a higher market value because of its superior brightness and fiber quality, which enhance final product characteristics. Understanding the balance between your operational costs and desired paper quality can help optimize your pulp selection for both profitability and performance.

Applications in the Paper Industry

Pine pulp is widely used in the paper industry for producing strong, durable paper products such as packaging materials, printing paper, and cardboard due to its long fibers that enhance tensile strength. Eucalyptus pulp, characterized by shorter fibers, is preferred for manufacturing fine printing paper, tissue paper, and high-quality coated paper because it offers smoothness and softness. Your choice between pine and eucalyptus pulp depends on the desired paper quality and application requirements in various paper products.

Sustainability and Certification

Pine pulp and eucalyptus pulp both stem from forestry practices that prioritize sustainability, with certifications like FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) ensuring responsible forest management. Eucalyptus pulp grows faster, offering a renewable resource with efficient land use, while pine pulp typically comes from slower-growing forests with longer rotation periods, affecting carbon sequestration. Your choice between pine and eucalyptus pulp can impact environmental footprints, especially when certified sources guarantee legal harvesting, biodiversity protection, and social responsibility.

Future Trends in Pulp Production

Future trends in pulp production highlight a shift towards sustainable and fast-growing fiber sources like eucalyptus pulp due to its higher yield and lower water consumption compared to pine pulp. Innovations in enzyme technology and biorefinery processes aim to enhance eucalyptus pulp's brightness and strength, making it a preferred choice for eco-friendly paper products. Increasing global demand for lightweight packaging and hygiene products further drives the expansion of eucalyptus pulp production over traditional pine pulp.

Pine pulp vs eucalyptus pulp Infographic

libmatt.com

libmatt.com