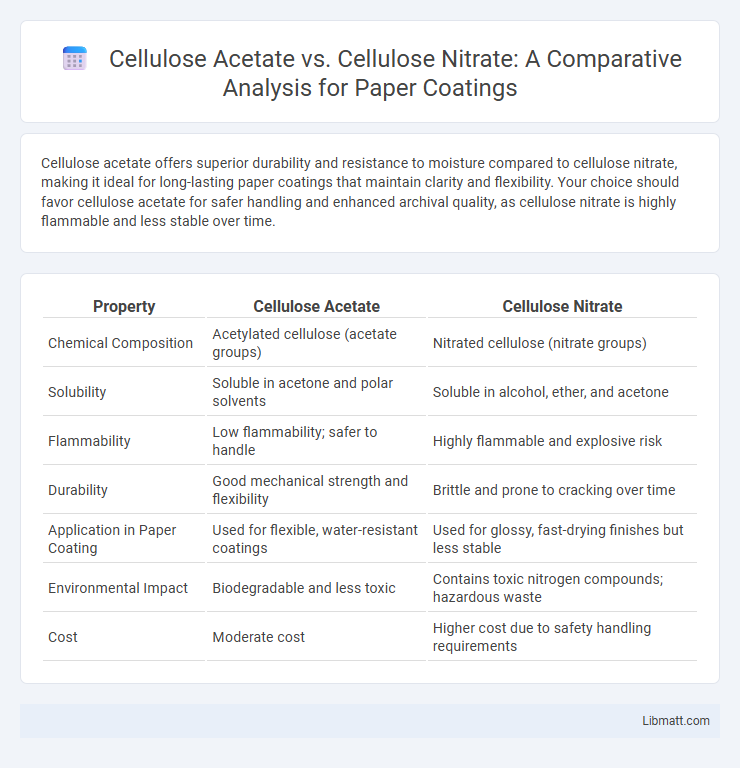

Cellulose acetate offers superior durability and resistance to moisture compared to cellulose nitrate, making it ideal for long-lasting paper coatings that maintain clarity and flexibility. Your choice should favor cellulose acetate for safer handling and enhanced archival quality, as cellulose nitrate is highly flammable and less stable over time.

Table of Comparison

| Property | Cellulose Acetate | Cellulose Nitrate |

|---|---|---|

| Chemical Composition | Acetylated cellulose (acetate groups) | Nitrated cellulose (nitrate groups) |

| Solubility | Soluble in acetone and polar solvents | Soluble in alcohol, ether, and acetone |

| Flammability | Low flammability; safer to handle | Highly flammable and explosive risk |

| Durability | Good mechanical strength and flexibility | Brittle and prone to cracking over time |

| Application in Paper Coating | Used for flexible, water-resistant coatings | Used for glossy, fast-drying finishes but less stable |

| Environmental Impact | Biodegradable and less toxic | Contains toxic nitrogen compounds; hazardous waste |

| Cost | Moderate cost | Higher cost due to safety handling requirements |

Introduction to Cellulose Acetate and Cellulose Nitrate

Cellulose acetate and cellulose nitrate are two prominent cellulose derivatives used in paper coatings, each offering distinct chemical and physical properties. Cellulose acetate provides excellent clarity, moisture resistance, and flexibility, making it ideal for protective and decorative coatings, while cellulose nitrate, known for its high flammability and rapid drying, is valued for producing glossy finishes and enhancing print sharpness. Your choice between these materials depends on the specific performance requirements and safety considerations of your paper coating application.

Historical Development of Paper Coatings

Cellulose acetate and cellulose nitrate played pivotal roles in the historical development of paper coatings, with cellulose nitrate emerging in the late 19th century as one of the first synthetic polymers used to enhance paper durability and water resistance. Cellulose acetate followed in the early 20th century, offering improved film-forming properties, clarity, and reduced flammability, which expanded its application in high-quality paper coatings. Understanding the evolution of these coatings helps you appreciate advancements in protective and functional paper finishes used in modern printing and packaging industries.

Chemical Structure Comparison

Cellulose acetate consists of cellulose molecules where hydroxyl groups are partially replaced by acetyl groups, resulting in a more stable and less flammable polymer ideal for paper coatings. Cellulose nitrate contains nitrate ester groups replacing hydroxyls, creating a highly combustible and less chemically stable compound. Your choice between these coatings impacts the durability and safety of the paper product due to their distinct chemical structures and reactivity.

Manufacturing Processes

Cellulose acetate and cellulose nitrate differ significantly in their manufacturing processes for paper coatings; cellulose acetate is produced by acetylation of cellulose fibers using acetic anhydride and acetic acid under controlled temperature and catalysts, resulting in a more stable and less flammable acetate ester. In contrast, cellulose nitrate is synthesized through nitration, where cellulose fibers undergo treatment with a mixture of nitric and sulfuric acids, creating highly flammable nitrocellulose with rapid drying properties. The precise control of reaction times, acid concentrations, and washing steps in both processes is crucial to achieving desirable film-forming characteristics and durability in coated papers.

Physical Properties and Performance

Cellulose acetate offers superior flexibility, durability, and resistance to moisture compared to cellulose nitrate, making it ideal for paper coatings requiring long-lasting performance. Cellulose nitrate, while highly flammable and less chemically stable, provides excellent transparency and hardness but degrades faster under environmental stress. Your choice between these coatings should balance durability needs with safety and environmental factors.

Durability and Preservation Concerns

Cellulose acetate offers superior durability compared to cellulose nitrate due to its greater resistance to yellowing, brittleness, and chemical degradation, making it more suitable for long-term paper coatings. Cellulose nitrate is highly flammable and prone to rapid deterioration, posing significant preservation challenges and safety hazards in archival environments. Preservation efforts prioritize cellulose acetate for its enhanced stability and reduced risk of fire and chemical breakdown in coated paper applications.

Safety and Environmental Impact

Cellulose acetate offers improved safety and environmental profiles compared to cellulose nitrate, as it is less flammable and produces fewer toxic combustion byproducts. Cellulose nitrate is highly flammable and poses significant fire hazards, releasing hazardous nitrogen oxides and other harmful gases during decomposition. Choosing cellulose acetate for paper coatings reduces risks associated with health and environmental pollution, promoting safer handling and disposal practices.

Applications in Paper Coating Industries

Cellulose acetate and cellulose nitrate serve distinct roles in paper coating industries, with cellulose acetate favored for its excellent film-forming properties, durability, and resistance to moisture, making it ideal for high-quality packaging and decorative paper coatings. Cellulose nitrate, known for its fast-drying capabilities and strong adhesion, is commonly used in specialty coatings requiring rapid set times, such as photographic papers and security documents. Your choice between these coatings depends on the desired balance between durability, drying speed, and the specific application requirements in paper production.

Cost and Availability

Cellulose acetate offers a cost-effective and widely available option for paper coatings due to its simpler production process and stable supply chains. Cellulose nitrate tends to be more expensive and less accessible, as its manufacturing involves hazardous chemicals and stricter regulations, limiting large-scale availability. Your choice may depend on budget constraints and the need for consistent material sourcing.

Future Trends in Paper Coating Materials

Cellulose acetate is gaining traction in paper coatings due to its biodegradability and excellent film-forming properties, making it a sustainable alternative to cellulose nitrate, which is known for its flammability and environmental concerns. Advances in nanotechnology and bio-based additives are expected to enhance the barrier and mechanical properties of cellulose acetate coatings, aligning with increasing regulatory pressures and consumer demand for eco-friendly packaging. Your choice of paper coating materials can benefit from these innovations, offering improved durability and environmental compliance in future applications.

Cellulose acetate vs cellulose nitrate (paper coatings) Infographic

libmatt.com

libmatt.com