Moisture content refers to the amount of water present in a material, directly affecting its structural integrity and performance, while humidity resistance measures a material's ability to withstand moisture absorption from the surrounding environment. Understanding the balance between these factors helps you select products that maintain durability and functionality under varying atmospheric conditions.

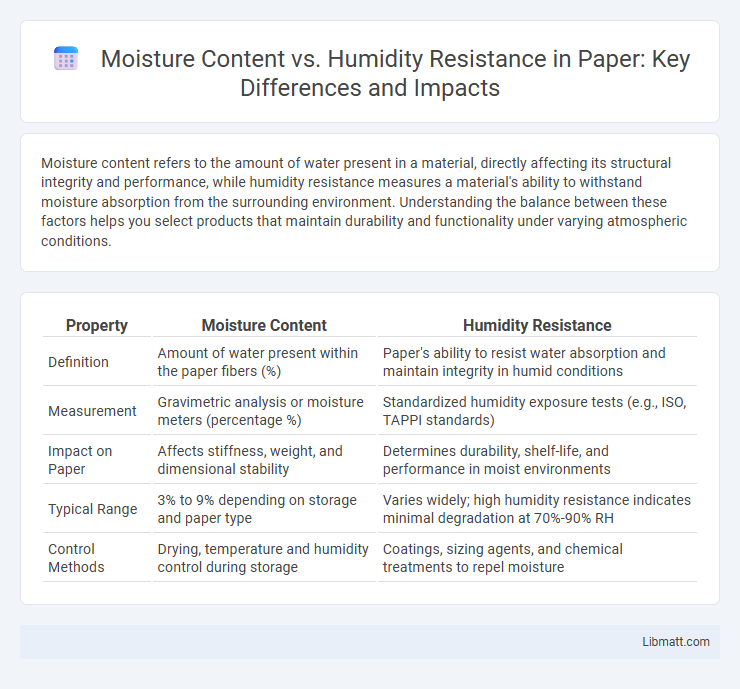

Table of Comparison

| Property | Moisture Content | Humidity Resistance |

|---|---|---|

| Definition | Amount of water present within the paper fibers (%) | Paper's ability to resist water absorption and maintain integrity in humid conditions |

| Measurement | Gravimetric analysis or moisture meters (percentage %) | Standardized humidity exposure tests (e.g., ISO, TAPPI standards) |

| Impact on Paper | Affects stiffness, weight, and dimensional stability | Determines durability, shelf-life, and performance in moist environments |

| Typical Range | 3% to 9% depending on storage and paper type | Varies widely; high humidity resistance indicates minimal degradation at 70%-90% RH |

| Control Methods | Drying, temperature and humidity control during storage | Coatings, sizing agents, and chemical treatments to repel moisture |

Understanding Moisture Content: Key Concepts

Moisture content refers to the amount of water present within a material, directly influencing its physical properties and durability. Materials with higher moisture content typically exhibit reduced humidity resistance, leading to degradation such as swelling, mold growth, or structural weakness. Precise measurement and control of moisture content are essential for enhancing humidity resistance in applications like construction, packaging, and electronics.

Defining Humidity Resistance in Materials

Humidity resistance in materials refers to the ability to withstand moisture exposure without degradation in physical or chemical properties. It is critical to differentiate humidity resistance from moisture content, as moisture content quantifies the actual water present within a material, while humidity resistance measures how well the material resists moisture absorption and damage over time. Understanding this distinction helps you select materials that maintain durability and performance in high-humidity environments.

The Science Behind Moisture and Humidity Interactions

Moisture content refers to the amount of water present within a material, while humidity resistance indicates a material's ability to withstand moisture absorption from the surrounding air. Understanding the science behind moisture and humidity interactions involves analyzing how water molecules diffuse into materials based on their hygroscopic properties and environmental conditions. Your selection of materials with optimal humidity resistance minimizes moisture-related degradation in applications sensitive to moisture content fluctuations.

Measurement Methods for Moisture Content

Accurate measurement of moisture content in materials relies on methods such as gravimetric analysis, where weight loss upon drying reveals water percentage, and electrical resistance sensors that detect changes in conductivity correlating to moisture levels. Advanced techniques like near-infrared spectroscopy offer non-destructive, real-time moisture quantification critical for assessing humidity resistance in building materials or packaging. Understanding your material's moisture content precisely allows for better control of its humidity resistance performance and durability.

Evaluating Humidity Resistance: Standards and Tests

Evaluating humidity resistance involves standardized tests such as ASTM D2247 and ISO 6270, which measure material performance under controlled high-humidity environments. Moisture content directly impacts a material's durability, influencing its ability to resist mold, corrosion, and dimensional changes during prolonged exposure to moisture. Your product's compliance with these standards ensures reliable performance and longevity in humid conditions.

Moisture Content’s Impact on Material Performance

Moisture content directly affects material performance by altering structural integrity, dimensional stability, and mechanical strength. High moisture content can lead to swelling, warping, and reduced load-bearing capacity in materials such as wood, polymers, and composites. Controlling moisture content is critical for enhancing humidity resistance, preventing degradation, and ensuring long-term durability in various environmental conditions.

Factors Influencing Humidity Resistance

Humidity resistance is primarily influenced by the moisture content of materials, material composition, and environmental conditions such as temperature and airflow. High moisture content often reduces a material's ability to resist humidity-related damage by promoting mold growth and structural degradation. Understanding these factors helps you select materials and treatments that enhance durability in humid environments.

Comparing Moisture Content and Humidity Resistance in Applications

Moisture content refers to the actual amount of water present within a material, significantly influencing its physical properties and performance. Humidity resistance measures a material's ability to withstand moisture absorption from the environment, critical for maintaining durability and structural integrity in variable atmospheric conditions. Comparing these factors helps industries select materials that balance internal moisture levels and external humidity exposure for optimal application performance.

Strategies to Improve Humidity Resistance Based on Moisture Content

Controlling moisture content is critical to enhancing humidity resistance in materials and products. Implementing moisture barriers, desiccants, and advanced coatings can significantly reduce moisture absorption and maintain structural integrity under high-humidity conditions. Understanding and managing your product's moisture content helps optimize performance and durability in environments prone to humidity fluctuations.

Future Trends in Managing Moisture and Humidity Challenges

Emerging technologies in moisture content measurement and humidity resistance materials are revolutionizing how industries manage environmental challenges. Advances in nanotechnology and smart sensors enable real-time monitoring and precise control of moisture levels, enhancing product durability and energy efficiency. Your ability to integrate these innovations will be crucial for competing in markets demanding high-performance moisture management solutions.

moisture content vs humidity resistance Infographic

libmatt.com

libmatt.com