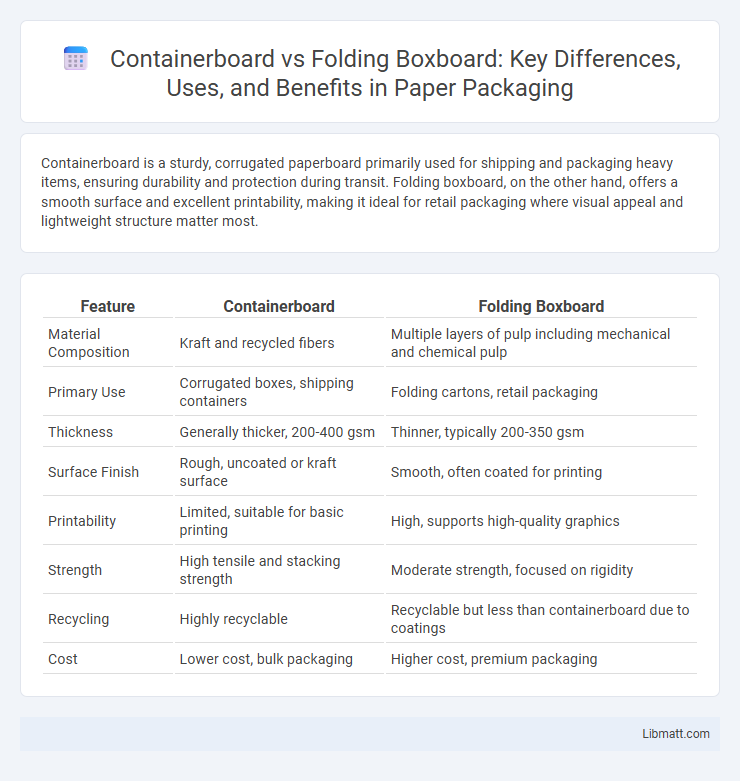

Containerboard is a sturdy, corrugated paperboard primarily used for shipping and packaging heavy items, ensuring durability and protection during transit. Folding boxboard, on the other hand, offers a smooth surface and excellent printability, making it ideal for retail packaging where visual appeal and lightweight structure matter most.

Table of Comparison

| Feature | Containerboard | Folding Boxboard |

|---|---|---|

| Material Composition | Kraft and recycled fibers | Multiple layers of pulp including mechanical and chemical pulp |

| Primary Use | Corrugated boxes, shipping containers | Folding cartons, retail packaging |

| Thickness | Generally thicker, 200-400 gsm | Thinner, typically 200-350 gsm |

| Surface Finish | Rough, uncoated or kraft surface | Smooth, often coated for printing |

| Printability | Limited, suitable for basic printing | High, supports high-quality graphics |

| Strength | High tensile and stacking strength | Moderate strength, focused on rigidity |

| Recycling | Highly recyclable | Recyclable but less than containerboard due to coatings |

| Cost | Lower cost, bulk packaging | Higher cost, premium packaging |

Introduction to Containerboard and Folding Boxboard

Containerboard is a robust type of paperboard primarily used for manufacturing corrugated boxes, featuring high durability and resistance to stacking loads. Folding boxboard, a multi-ply paperboard made from layers of chemical and mechanical pulp, offers a smooth surface ideal for printing and packaging consumer goods. Both materials serve distinct roles in packaging, with containerboard optimized for structural strength and folding boxboard preferred for aesthetic appeal and lightweight protection.

Composition and Material Differences

Containerboard is primarily made from recycled fibers or kraft pulp, featuring a linerboard and a corrugated medium designed for strength and cushioning in shipping applications. Folding boxboard, composed of multiple layers including mechanical pulp and chemical pulp with a bleached chemical pulp top layer, provides superior stiffness, printability, and smoothness ideal for retail packaging. Your choice between the two hinges on whether structural durability or high-quality appearance is the priority.

Manufacturing Processes Compared

Containerboard is produced primarily through a kraft process using softwood fibers that create strong, durable liners and fluting essential for corrugated packaging, emphasizing high tensile strength and burst resistance. Folding boxboard, on the other hand, involves a multilayer manufacturing process with a bleached chemical pulp top layer and mechanical pulp layers beneath, resulting in a smooth surface ideal for high-quality printing and folding. These distinct manufacturing methods reflect containerboard's focus on structural integrity for shipping and folding boxboard's priority on visual appeal and foldability in retail packaging.

Strength and Durability

Containerboard offers superior strength and durability due to its thicker, multi-ply construction, making it ideal for heavy-duty packaging and shipping applications. Folding boxboard, while lighter and more flexible, provides sufficient durability for retail packaging but may not withstand rough handling as effectively as containerboard. Your packaging choice should consider the required load-bearing capacity and environmental conditions to ensure optimal protection.

Printability and Surface Quality

Containerboard typically has a rougher surface with lower printability due to its uncoated fibers, making it ideal for corrugated packaging but less suitable for high-quality graphics. Folding boxboard offers superior surface smoothness and better printability, allowing for vibrant, detailed, and high-resolution printing essential for premium retail packaging. The coated layers in folding boxboard enhance ink adhesion and color vibrancy, ensuring consistent image quality compared to the porous surface of containerboard.

Applications and End Uses

Containerboard primarily serves in shipping and packaging applications due to its strength and durability, making it ideal for corrugated boxes used in transporting goods. Folding boxboard is favored for consumer packaging such as cosmetics, food, and pharmaceuticals, where printability and visual appeal are crucial. Your choice depends on whether structural strength or high-quality surface finish is prioritized in the end use.

Sustainability and Environmental Impact

Containerboard offers superior sustainability through its high recycled fiber content, reducing deforestation and landfill waste, while its recyclability supports circular economy goals. Folding boxboard, made from virgin fibers and often bleached, provides strength and printability but has a higher carbon footprint and energy consumption during production. Both materials contribute to eco-friendly packaging solutions, but containerboard's emphasis on recycled materials and lower environmental impact makes it a preferred choice for sustainable packaging initiatives.

Cost and Market Availability

Containerboard generally offers a lower cost per ton compared to folding boxboard, making it a preferred choice for bulk packaging and shipping applications. Folding boxboard, known for its superior printability and stiffness, commands a higher price point and is widely available in markets targeting premium retail packaging. Market availability for containerboard remains robust due to its essential role in e-commerce and industrial packaging, while folding boxboard sees strong demand in consumer goods sectors where visual appeal is critical.

Key Industry Standards

Containerboard is primarily standardized by the Kraft process, adhering to the International Corrugated Packaging Foundation (ICPF) and the European Federation of Corrugated Board Manufacturers (FEFCO) guidelines to ensure strength and durability for shipping applications. Folding boxboard complies with standards set by the European Carton Makers Association (ECMA) and the International Organization for Standardization (ISO 9001) to guarantee smooth surface finish and printability for consumer packaging. Both materials must meet specific grammage, thickness, and burst strength requirements to fulfill their respective functional roles in the packaging industry.

Choosing the Right Board for Your Packaging Needs

Containerboard offers superior strength and cushioning, making it ideal for shipping heavy or fragile items, while folding boxboard provides excellent printability and smooth surface finish suited for retail packaging and display boxes. Understanding your product's protection requirements and visual appeal is key to choosing the right board for your packaging needs. You should prioritize durability with containerboard for transport resilience or opt for folding boxboard when attractive presentation and lightweight packaging are essential.

containerboard vs folding boxboard Infographic

libmatt.com

libmatt.com