Double-side coated materials offer enhanced durability and protection on both surfaces, making them ideal for applications requiring resistance from all angles. Single-side coated options provide a protective or functional layer on one side only, which may be suitable for projects where only one surface needs treatment or insulation.

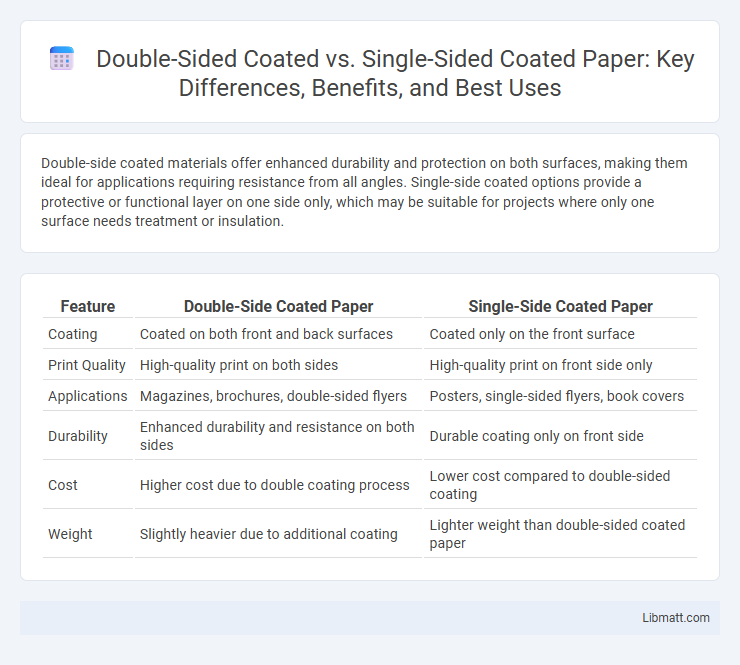

Table of Comparison

| Feature | Double-Side Coated Paper | Single-Side Coated Paper |

|---|---|---|

| Coating | Coated on both front and back surfaces | Coated only on the front surface |

| Print Quality | High-quality print on both sides | High-quality print on front side only |

| Applications | Magazines, brochures, double-sided flyers | Posters, single-sided flyers, book covers |

| Durability | Enhanced durability and resistance on both sides | Durable coating only on front side |

| Cost | Higher cost due to double coating process | Lower cost compared to double-sided coating |

| Weight | Slightly heavier due to additional coating | Lighter weight than double-sided coated paper |

Introduction to Paper Coating Types

Double-side coated paper features a coating on both front and back surfaces, enhancing its smoothness, gloss, and print quality for high-end publications, brochures, and art prints. Single-side coated paper has a coating applied only to the front, balancing print quality with cost-effectiveness and better performance for writing or uncoated backs. The choice between double-side and single-side coated papers depends on the desired durability, aesthetic appeal, and printing technique requirements.

What Is Single-Side Coated Paper?

Single-side coated paper features a coating applied exclusively on one side, enhancing print quality by providing a smooth, glossy or matte finish that improves color vibrancy and sharpness. This type of paper is ideal for printing projects where only one side requires high-definition graphics, such as brochures, flyers, and direct mail pieces. The uncoated back allows for easier handling and writing, making it popular for marketing materials that combine visual appeal with practical functionality.

What Is Double-Side Coated Paper?

Double-side coated paper features a coating layer applied on both the front and back surfaces, enhancing print quality, brightness, and smoothness on each side. This type of paper is commonly used in high-end printing projects like brochures and magazines where both sides require vibrant color reproduction and sharp detail. Its balanced coating prevents ink bleed-through and supports consistent performance in duplex printing systems.

Manufacturing Process Differences

Double-side coated materials undergo simultaneous application of coatings on both surfaces, requiring precise control to ensure uniform thickness and adhesion on each side, while single-side coated materials involve coating only one surface, simplifying the machinery and drying process. The manufacturing process for double-side coated products demands advanced curing techniques to avoid defects such as uneven textures or curling, which are less common in single-side coated production lines. Understanding these differences helps you choose materials based on production efficiency and performance requirements.

Print Quality Comparison

Double-side coated paper provides superior print quality by offering consistent ink absorption on both sides, resulting in sharper images and vibrant colors without bleed-through. Single-side coated paper typically delivers high-quality prints only on the coated side, with the uncoated side prone to ink absorption inconsistencies and duller visuals. Choosing double-side coated paper enhances your project's overall appearance, especially for duplex printing where balanced print clarity is essential.

Applications of Single-Side Coated Paper

Single-side coated paper is extensively used in packaging, labels, and printed materials where one glossy or matte finish side is required for improved print quality and ink adhesion. It is ideal for applications such as book covers, posters, and promotional flyers where one side needs to be visually appealing while the other side remains uncoated for easier handling or writing. This type of paper balances cost efficiency and functional performance, making it a preferred choice in commercial printing and consumer goods packaging.

Uses for Double-Side Coated Paper

Double-side coated paper is primarily used for high-quality printing applications that demand superior image clarity and color vibrancy on both sides, such as magazines, brochures, and catalogs. Its smooth surfaces enhance ink absorption evenly on each side, making it ideal for double-sided printing without bleed-through or show-through issues. This type of paper is favored in commercial printing environments where durability and visual appeal are critical for marketing materials and high-end publications.

Cost and Budget Considerations

Double-side coated materials typically incur higher production costs due to the additional coating process on both sides, impacting the overall budget significantly. Single-side coated options present a more cost-effective solution by limiting the coating to one surface, reducing material and manufacturing expenses. For projects with tight budget constraints, single-side coated products offer better economic value without sacrificing essential functionality.

Environmental Impact and Sustainability

Double-side coated materials reduce waste by enabling both surfaces to be utilized, enhancing resource efficiency compared to single-side coated options. These coatings often feature eco-friendly formulations that minimize harmful emissions and facilitate easier recycling processes. Choosing double-side coated products can support your sustainability goals by lowering environmental footprint through better material optimization and reduced landfill contributions.

Choosing the Right Coating for Your Project

Double-side coated materials offer enhanced durability and uniform protection on both surfaces, making them ideal for projects requiring balanced strength and moisture resistance. Single-side coated options provide a cost-effective solution when only one surface demands functional treatment, such as waterproofing or printability. Consider the environmental exposure and performance needs of your project to select the appropriate coating that ensures optimal results and longevity.

double-side coated vs single-side coated Infographic

libmatt.com

libmatt.com