Machine glazed surfaces have a shiny, smooth appearance created by reheating and pressing the clay, making them less durable but more economical for decorative purposes. Machine finished surfaces undergo additional mechanical processes like sanding or polishing, resulting in a more consistent, refined texture that enhances durability and functionality.

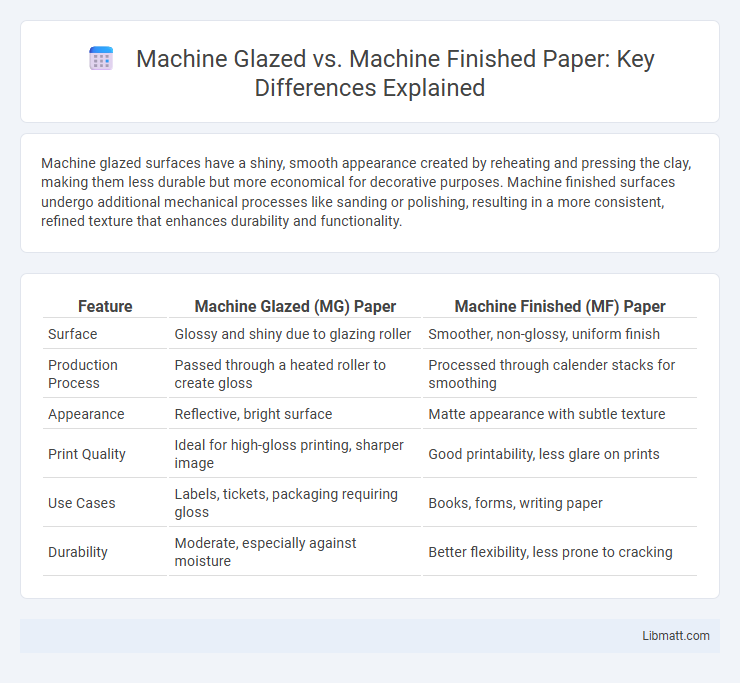

Table of Comparison

| Feature | Machine Glazed (MG) Paper | Machine Finished (MF) Paper |

|---|---|---|

| Surface | Glossy and shiny due to glazing roller | Smoother, non-glossy, uniform finish |

| Production Process | Passed through a heated roller to create gloss | Processed through calender stacks for smoothing |

| Appearance | Reflective, bright surface | Matte appearance with subtle texture |

| Print Quality | Ideal for high-gloss printing, sharper image | Good printability, less glare on prints |

| Use Cases | Labels, tickets, packaging requiring gloss | Books, forms, writing paper |

| Durability | Moderate, especially against moisture | Better flexibility, less prone to cracking |

Introduction to Machine Glazed and Machine Finished Papers

Machine glazed paper features a high-gloss surface achieved by pressing the paper against a highly polished roller during production, enhancing smoothness and printability for packaging and labels. Machine finished paper undergoes surface treatments on both sides, resulting in a uniform finish with improved strength and print quality, commonly used in printing and writing applications. These production techniques optimize paper properties by controlling fiber alignment and surface texture to meet specific end-use requirements.

Defining Machine Glazed Paper

Machine glazed paper features a smooth, shiny surface created during manufacturing by pressing the paper against a highly polished cylinder, enhancing its gloss and making it ideal for printing crisp images. This machine finishing technique differs from standard machine finished paper, which has a matte appearance and uniform texture without the reflective sheen. Understanding the definition of machine glazed paper helps you choose the right finish for projects requiring vibrant visual appeal and smooth touch.

Defining Machine Finished Paper

Machine finished paper refers to paper that undergoes a smoothing process on a machine, enhancing surface texture and improving printability without applying additional coatings. This finishing technique uses mechanical calendering to compress the fibers, resulting in a uniform and slightly glossy surface suitable for various printing applications. Unlike machine glazed paper, which produces a highly glossy finish on one side, machine finished paper offers a balanced surface ideal for both sides, maintaining durability and versatility.

Key Differences Between Machine Glazed and Machine Finished

Machine glazed surfaces have a glossy, reflective finish created by passing the ceramic through a highly polished roller, resulting in a smooth but less durable coating prone to scratching. Machine finished tiles undergo mechanical polishing that enhances texture and durability without adding a gloss, offering a more natural, matte appearance resistant to wear. Your choice depends on whether you prioritize surface shine or long-term resilience in high-traffic areas.

Production Processes: Machine Glazing vs. Machine Finishing

Machine glazing involves reheating a previously fired ceramic surface, then polishing it with heavy rollers to create a smooth, reflective finish that enhances the tile's appearance and water resistance. Machine finishing, on the other hand, refines the surface texture through mechanical abrasion or grinding without reheating, resulting in a more tactile, matte, or textured effect with increased slip resistance. You can choose between these production processes based on whether you prioritize glossy aesthetics or functional surface characteristics for your tiles.

Surface Characteristics and Appearance Comparison

Machine glazed surfaces exhibit a glossy, reflective finish created by passing the ceramic tile through a high-temperature roller, resulting in a smooth and polished appearance with slight variations in texture. Machine finished tiles are mechanically honed or ground to achieve a uniform, matte, or semi-matte surface with consistent texture and less shine, offering enhanced slip resistance. Understanding the differences helps you choose the ideal surface for aesthetic preferences and practical applications in your space.

Common Applications of Machine Glazed Paper

Machine glazed paper is commonly used in applications requiring high brightness and a smooth, glossy finish, such as gift wrapping, book covers, and food packaging. Its one-sided sheen enhances print quality and visual appeal, making it ideal for labels and tags in retail settings. The durability and moisture resistance of machine glazed paper also suit it for photographic paper and other specialty printing needs.

Typical Uses for Machine Finished Paper

Machine finished paper is commonly used in printing, book publishing, and stationery due to its smooth surface that enhances ink adhesion and print clarity. It is ideal for high-quality text documents, magazines, and brochures where sharp image reproduction is essential. This type of paper balances cost and performance, making it suitable for everyday commercial applications requiring precise and professional printing results.

Advantages and Disadvantages of Each Paper Type

Machine glazed paper offers a high-gloss finish with enhanced smoothness and moisture resistance, making it ideal for packaging and labels, but its stiffness and limited opacity can be drawbacks. Machine finished paper provides better printability and flexibility due to its smoother surface on both sides, though it may lack the shiny appeal and water resistance found in machine glazed options. Your choice depends on whether you prioritize visual impact and durability or versatility and ease of printing.

Choosing the Right Paper: Factors to Consider

Selecting between machine glazed and machine finished paper depends on your project's needs, as machine glazed paper offers a glossy, smooth surface ideal for high-quality printing and packaging, while machine finished paper provides a more matte, uniform texture suited for writing and general use. Consider the desired finish, print quality, and application to determine which paper will enhance Your product's appearance and functionality. Understanding the differences in surface treatment and durability will help you make an informed decision tailored to Your specific requirements.

machine glazed vs machine finished Infographic

libmatt.com

libmatt.com