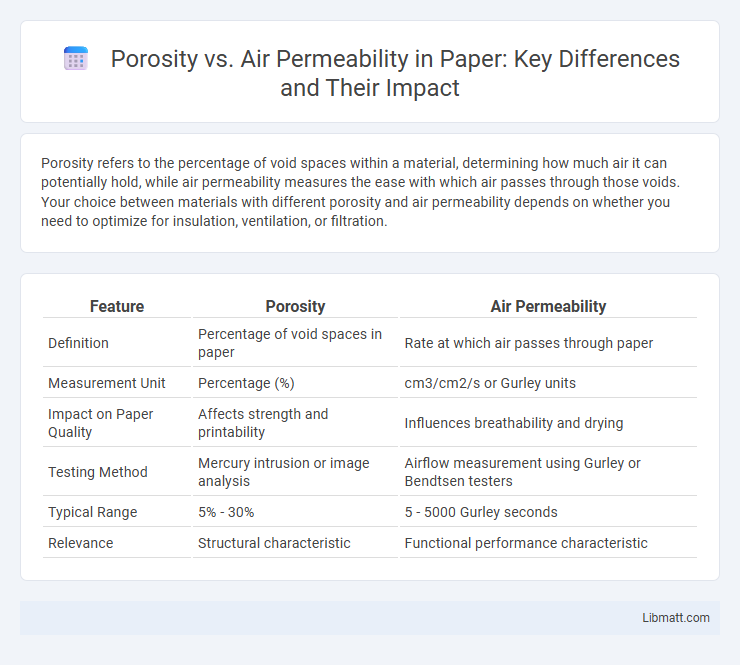

Porosity refers to the percentage of void spaces within a material, determining how much air it can potentially hold, while air permeability measures the ease with which air passes through those voids. Your choice between materials with different porosity and air permeability depends on whether you need to optimize for insulation, ventilation, or filtration.

Table of Comparison

| Feature | Porosity | Air Permeability |

|---|---|---|

| Definition | Percentage of void spaces in paper | Rate at which air passes through paper |

| Measurement Unit | Percentage (%) | cm3/cm2/s or Gurley units |

| Impact on Paper Quality | Affects strength and printability | Influences breathability and drying |

| Testing Method | Mercury intrusion or image analysis | Airflow measurement using Gurley or Bendtsen testers |

| Typical Range | 5% - 30% | 5 - 5000 Gurley seconds |

| Relevance | Structural characteristic | Functional performance characteristic |

Understanding Porosity: Definition and Importance

Porosity refers to the measure of void spaces within a material, influencing its capacity to store and transmit fluids like air or water. Understanding porosity is crucial for evaluating air permeability, as higher porosity typically indicates greater potential for air flow through a substance. You can optimize material selection and design by accurately assessing porosity to ensure desired ventilation and breathability performance.

Air Permeability Explained: Key Concepts

Air permeability measures a material's ability to allow air to pass through its porous structure, directly influenced by porosity, which quantifies the volume percentage of void spaces within a material. High porosity typically increases air permeability, but factors like pore size, shape, and connectivity critically determine the rate of airflow. Understanding these relationships is essential for applications in construction, filtration, and textile engineering, where material breathability and ventilation efficiency are prioritized.

How Porosity and Air Permeability Are Related

Porosity and air permeability are closely related properties of materials that influence airflow and filtration efficiency. Porosity refers to the volume fraction of void spaces within a material, while air permeability measures the ease with which air passes through these voids. Higher porosity generally indicates greater air permeability, but factors such as pore size distribution and connectivity also critically affect airflow rates.

Measurement Techniques for Porosity

Measurement techniques for porosity include mercury intrusion porosimetry, which assesses pore size distribution and volume by forcing mercury into the material under controlled pressure. Gas pycnometry calculates porosity by measuring the volume of gas displaced by the sample, providing precise data on interconnected pore space. Optical microscopy and image analysis also quantify porosity by directly visualizing and measuring pore structures in materials.

Methods for Assessing Air Permeability

Air permeability is assessed through standardized methods such as the Gurley method, which measures the time required for a specific volume of air to pass through a fabric under controlled pressure conditions, and the Constant Pressure method that evaluates airflow rate at a constant differential pressure. These techniques provide quantitative data on material porosity but focus specifically on air flow characteristics rather than total void volume. Understanding these methods helps you accurately gauge a material's breathability and filtration efficiency in applications like textiles and filtration media.

Factors Influencing Porosity in Materials

Porosity in materials is primarily influenced by factors such as particle size, distribution, and the compaction process during manufacturing, which determine the void spaces within the structure. Air permeability, although related, depends more on the connectivity and size of these voids rather than just their volume. Understanding these factors helps optimize your material's efficiency in applications requiring specific airflow or insulation properties.

Variables Affecting Air Permeability

Air permeability is influenced by factors such as pore size distribution, pore connectivity, and fabric thickness, which control the ease of air flow through a material. Porosity alone does not determine air permeability since the shape and arrangement of pores critically affect resistance to airflow. Material density and fiber orientation also play significant roles in modifying how air permeates porous structures.

Comparative Analysis: Porosity vs Air Permeability

Porosity measures the volume fraction of void spaces in a material, directly influencing its capacity to hold fluids or gases, while air permeability quantifies how easily air flows through these void spaces under a pressure gradient. High porosity does not always guarantee high air permeability, as pore size distribution and connectivity critically affect airflow dynamics. Understanding the comparative differences between porosity and air permeability helps optimize material selection for applications requiring precise control over gas exchange and filtration.

Applications: Why Porosity and Air Permeability Matter

Porosity determines a material's ability to hold fluids, making it crucial in filtration, soil science, and construction where fluid retention impacts performance. Air permeability measures how easily air passes through a material, essential for applications in ventilation, breathable textiles, and insulation to regulate airflow and maintain comfort. Understanding both properties enables engineers to design systems that balance moisture control and ventilation for optimal efficiency and durability.

Practical Examples in Industry and Research

Porosity and air permeability play critical roles in industries such as filtration, construction, and textiles, where materials like ceramic filters, concrete, and breathable fabrics are optimized for specific applications. Porosity determines the total void space within a material, influencing properties like insulation and fluid storage, while air permeability measures the ease with which air passes through those voids, directly impacting ventilation and filtration efficiency. Understanding the relationship between these properties allows researchers and engineers to tailor materials for improved performance in sectors ranging from environmental monitoring to protective clothing.

porosity vs air permeability Infographic

libmatt.com

libmatt.com