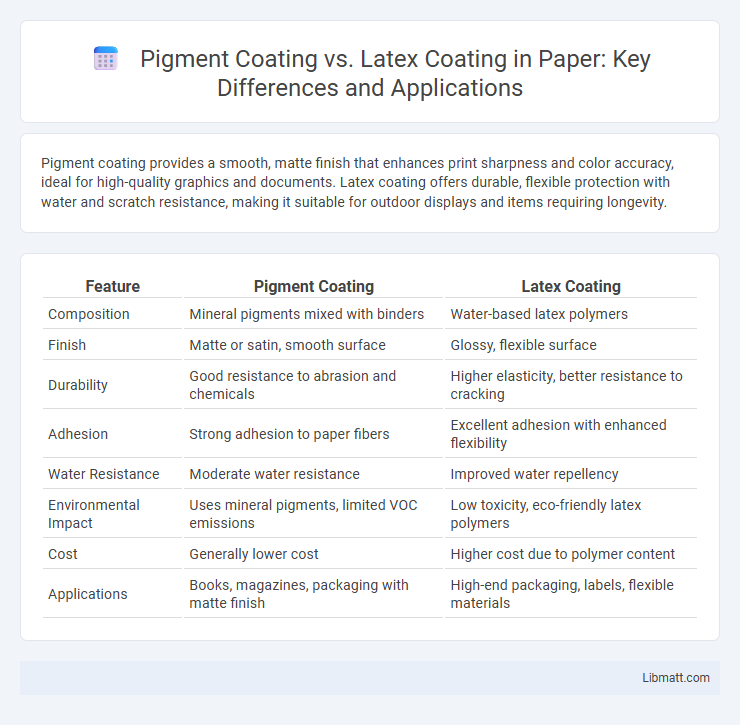

Pigment coating provides a smooth, matte finish that enhances print sharpness and color accuracy, ideal for high-quality graphics and documents. Latex coating offers durable, flexible protection with water and scratch resistance, making it suitable for outdoor displays and items requiring longevity.

Table of Comparison

| Feature | Pigment Coating | Latex Coating |

|---|---|---|

| Composition | Mineral pigments mixed with binders | Water-based latex polymers |

| Finish | Matte or satin, smooth surface | Glossy, flexible surface |

| Durability | Good resistance to abrasion and chemicals | Higher elasticity, better resistance to cracking |

| Adhesion | Strong adhesion to paper fibers | Excellent adhesion with enhanced flexibility |

| Water Resistance | Moderate water resistance | Improved water repellency |

| Environmental Impact | Uses mineral pigments, limited VOC emissions | Low toxicity, eco-friendly latex polymers |

| Cost | Generally lower cost | Higher cost due to polymer content |

| Applications | Books, magazines, packaging with matte finish | High-end packaging, labels, flexible materials |

Overview of Pigment Coating and Latex Coating

Pigment coating creates a smooth, glossy surface by applying a layer of fine mineral pigments bonded with a binder, enhancing print quality and durability. Latex coating uses a water-based polymer dispersion that forms a flexible, protective film, improving resistance to scuffing and moisture. Your choice depends on the desired finish and functional requirements, with pigment coating favored for sharp image clarity and latex coating preferred for durability and eco-friendliness.

Key Differences Between Pigment and Latex Coatings

Pigment coatings primarily provide color and opacity with excellent UV resistance, making them ideal for outdoor applications, while latex coatings offer superior flexibility, adhesion, and resistance to cracking, suitable for indoor and exterior surfaces. Pigment coatings are based on solid color particles suspended in a binder, whereas latex coatings consist of water-based polymers that form a durable film. Latex coatings typically dry faster and are easier to clean up, whereas pigment coatings create a more matte finish with enhanced durability against fading and weathering.

Composition and Chemical Properties

Pigment coating primarily consists of fine mineral particles such as calcium carbonate or kaolin, bonded with binders like latex or starch, providing a smooth, matte surface with enhanced printability and opacity. Latex coating is based on synthetic polymer emulsions, typically acrylic or styrene-butadiene latex, which create a flexible, water-resistant film that improves durability and gloss. Chemically, pigment coatings focus on opacity and surface texture through inorganic fillers, while latex coatings emphasize polymer film formation for moisture resistance and elasticity.

Application Methods for Each Coating Type

Pigment coatings are commonly applied using roll coating or curtain coating methods, which ensure uniform coverage and are ideal for smooth, high-gloss finishes on paper and cardboard. Latex coatings, on the other hand, often utilize spray or air-knife coating techniques, providing excellent adhesion and flexibility suited for textiles, packaging, and flexible materials. Your choice of application method should align with the substrate type and desired durability to optimize coating performance.

Surface Finish and Appearance Comparison

Pigment coating offers a smooth, vibrant surface finish with excellent opacity and color uniformity, ideal for high-quality printing and detailed graphics. Latex coating provides a flexible, glossy finish that enhances durability and water resistance while maintaining consistent color and brightness. Your choice depends on whether you prioritize sharper visual clarity with pigment or enhanced sheen and protection with latex.

Durability and Performance Factors

Pigment coating offers superior scratch resistance and UV stability, making it ideal for outdoor applications requiring long-lasting color retention and protection. Latex coating provides excellent flexibility and water resistance, which enhances durability under frequent handling and exposure to moisture. Your choice depends on whether you prioritize hard surface durability with pigment coatings or the adaptable, resilient performance of latex coatings.

Environmental Impact and VOC Emissions

Pigment coating typically involves solvent-based formulations that can emit higher levels of volatile organic compounds (VOCs), contributing to air pollution and health risks. Latex coatings, derived from water-based formulas, generally produce significantly lower VOC emissions, making them more environmentally friendly and safer for indoor air quality. The reduced environmental impact of latex coatings aligns with stricter regulatory standards and growing industry demands for sustainable building materials.

Cost Analysis: Pigment vs Latex Coatings

Pigment coatings generally offer a lower upfront cost compared to latex coatings, making them a budget-friendly option for large-scale applications. Latex coatings, while more expensive initially, provide better durability and resistance to environmental factors, potentially reducing long-term maintenance expenses. Your choice should balance initial cost savings with the extended lifespan benefits of latex to optimize overall expenditure.

Best Use Cases and Industry Applications

Pigment coating excels in packaging and printing industries where high opacity and colorfastness are essential for product labels and cartons. Latex coating is preferred in textiles, automotive, and furniture sectors due to its flexibility, water resistance, and durability on fabrics and surfaces. Both coatings serve niche applications; pigment coatings emphasize visual quality and protection, while latex coatings provide enhanced adhesion and environmental resistance.

Making the Right Choice: Pigment or Latex Coating?

Choosing between pigment coating and latex coating depends on your specific application needs and desired finish durability. Pigment coatings offer superior color stability and UV resistance, making them ideal for outdoor surfaces requiring long-lasting vibrancy, while latex coatings provide excellent flexibility, adhesion, and are more environmentally friendly, suitable for interior walls and surfaces prone to movement. Understanding your project's exposure conditions and aesthetic goals will help you make the right choice between pigment or latex coating.

pigment coating vs latex coating Infographic

libmatt.com

libmatt.com