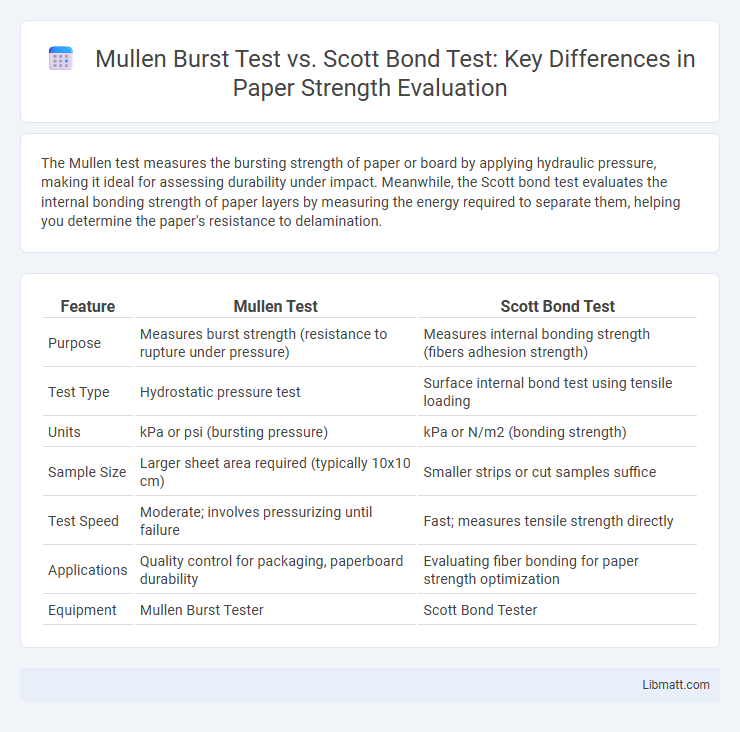

The Mullen test measures the bursting strength of paper or board by applying hydraulic pressure, making it ideal for assessing durability under impact. Meanwhile, the Scott bond test evaluates the internal bonding strength of paper layers by measuring the energy required to separate them, helping you determine the paper's resistance to delamination.

Table of Comparison

| Feature | Mullen Test | Scott Bond Test |

|---|---|---|

| Purpose | Measures burst strength (resistance to rupture under pressure) | Measures internal bonding strength (fibers adhesion strength) |

| Test Type | Hydrostatic pressure test | Surface internal bond test using tensile loading |

| Units | kPa or psi (bursting pressure) | kPa or N/m2 (bonding strength) |

| Sample Size | Larger sheet area required (typically 10x10 cm) | Smaller strips or cut samples suffice |

| Test Speed | Moderate; involves pressurizing until failure | Fast; measures tensile strength directly |

| Applications | Quality control for packaging, paperboard durability | Evaluating fiber bonding for paper strength optimization |

| Equipment | Mullen Burst Tester | Scott Bond Tester |

Introduction to Mullen and Scott Bond Tests

The Mullen test measures the bursting strength of paper by applying hydraulic pressure to a sample until it ruptures, offering critical data on material durability for packaging and printing industries. The Scott Bond test assesses the internal bonding strength of paper by determining the energy required to delaminate paper plies, providing insights into paper's structural integrity and resistance to delamination. Both tests are essential for evaluating paper quality but focus on different mechanical properties, with Mullen addressing burst resistance and Scott Bond emphasizing internal fiber bonding.

Overview of Paper Strength Testing Methods

Mullen test and Scott bond test are essential methods for evaluating paper strength, with the Mullen test measuring burst strength by applying hydraulic pressure until rupture, indicating the paper's resistance to stress. Scott bond test assesses internal bond strength by quantifying the force required to delaminate paper layers, providing critical data on cohesion and bonding quality. Both tests offer complementary insights for quality control and product development in the paper industry.

What is the Mullen Test?

The Mullen Test measures the bursting strength of paper or cardboard by applying uniform pressure until the sample ruptures, providing critical data on material durability. This test complements the Scott Bond Test, which assesses internal bond strength between fibers through a rapid impact method, highlighting different aspects of paper performance. Understanding the Mullen Test helps you evaluate the resistance of packaging materials to pressure, essential for quality control in manufacturing.

What is the Scott Bond Test?

The Scott Bond Test measures the internal bonding strength of paper by determining the energy required to propagate a crack within the sheet, expressed in joules per square meter (J/m2). This test evaluates paper's resistance to delamination, making it critical for packaging and printing quality. Understanding your material's Scott Bond value ensures better durability and performance in its intended application.

Key Differences Between Mullen and Scott Bond Tests

The Mullen test measures the bursting strength of paper and cardboard by applying hydraulic pressure until the sample ruptures, making it ideal for evaluating packaging materials' resistance to sudden stress. The Scott Bond test assesses internal tearing resistance by applying repeated pendulum impacts to measure the energy required to propagate a tear, providing insights into paper's toughness and durability under dynamic forces. Unlike the Mullen test's focus on ultimate strength, the Scott Bond test emphasizes tear resistance, crucial for quality control in paper converting processes.

Applications of Mullen Test in Industry

The Mullen Test is widely applied in the paper and packaging industries to measure the burst strength of paperboard, ensuring material durability for packaging heavy or sharp-edged goods. Its ability to evaluate the resistance of paper to rupture under pressure makes it essential for quality control in manufacturing corrugated cartons and multi-ply packaging materials. Industries rely on the Mullen Test to guarantee product safety and compliance with international packaging standards.

Uses of Scott Bond Test in Paper Quality Assessment

The Scott Bond test evaluates the internal bond strength of paper by measuring the energy needed to rupture the paper layers, crucial for assessing packaging materials' durability. This test helps determine the paper's resistance to delamination, making it vital for quality control in corrugated boards and laminated products. In contrast, while the Mullen test focuses on bursting strength related to tensile stress, the Scott Bond test provides insights into the paper's internal adhesion and structural integrity.

Advantages and Limitations of Each Test

The Mullen test offers quick and straightforward measurement of paper bursting strength, making it ideal for assessing packaging durability in various industries. However, it may not accurately reflect the material's resistance to localized forces or flexing, limiting its effectiveness for certain applications. The Scott bond test excels at determining the internal bond strength of paper and board, providing valuable insight into material integrity and printability, but it is less suited for evaluating overall tensile strength or resistance to surface impact.

Choosing the Right Test for Your Paper Product

Selecting the appropriate test between the Mullen and Scott Bond tests depends on the specific strength characteristics you need to evaluate for your paper product. The Mullen test measures burst strength, indicating resistance to pressure and puncture, while the Scott Bond test assesses internal bond strength, reflecting the paper's ability to withstand internal stresses. Your choice should align with the performance requirements of your product, ensuring optimal durability and quality control.

Future Trends in Paper Strength Testing

Future trends in paper strength testing emphasize integrating digital technologies like AI and machine learning to enhance the precision of Mullen and Scott Bond tests. These advancements aim to provide real-time, automated analysis of tensile strength, burst strength, and internal bonding, enabling you to optimize paper quality more efficiently. Innovations in sensor technology and data analytics are expected to drive more accurate material characterization and predictive maintenance in the paper manufacturing industry.

Mullen test vs Scott bond test Infographic

libmatt.com

libmatt.com