Machine direction (MD) refers to the orientation parallel to the flow of material during manufacturing, impacting properties like tensile strength and elongation, while cross direction (CD) is perpendicular to MD and affects characteristics such as width stability and tear resistance. Understanding the differences between MD and CD is crucial for optimizing the performance and durability of materials in applications like paper, textiles, and films.

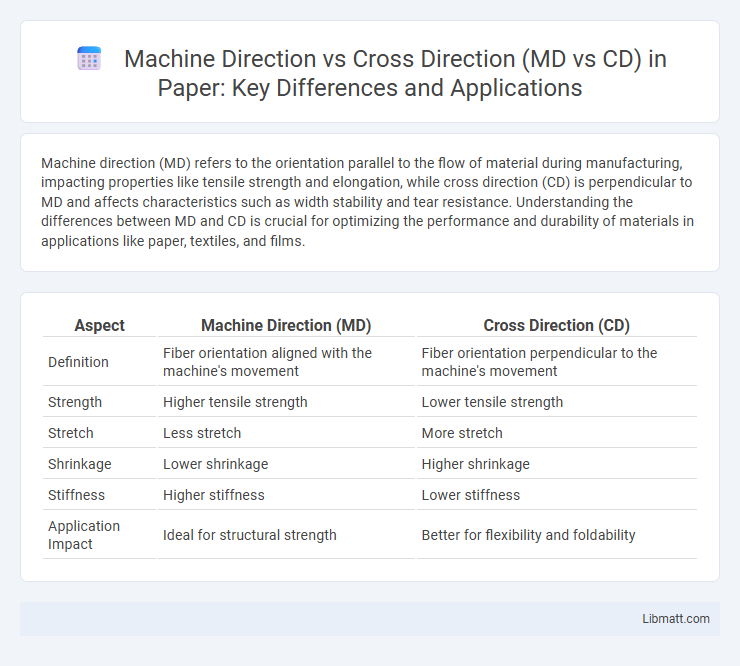

Table of Comparison

| Aspect | Machine Direction (MD) | Cross Direction (CD) |

|---|---|---|

| Definition | Fiber orientation aligned with the machine's movement | Fiber orientation perpendicular to the machine's movement |

| Strength | Higher tensile strength | Lower tensile strength |

| Stretch | Less stretch | More stretch |

| Shrinkage | Lower shrinkage | Higher shrinkage |

| Stiffness | Higher stiffness | Lower stiffness |

| Application Impact | Ideal for structural strength | Better for flexibility and foldability |

Introduction to Machine Direction (MD) and Cross Direction (CD)

Machine Direction (MD) refers to the orientation of fibers or material flow along the length of a web or sheet, influencing tensile strength and elongation properties in that direction. Cross Direction (CD) runs perpendicular to MD, affecting widthwise stability and resistance to tearing or deformation. Understanding the differences between MD and CD is crucial for optimizing your manufacturing processes and ensuring the desired strength and flexibility of materials like paper, textiles, or films.

Defining MD and CD in Material Processing

Machine Direction (MD) refers to the orientation parallel to the flow of a material as it moves through the production line, significantly impacting tensile strength, elongation, and stiffness due to fiber alignment or polymer chain orientation. Cross Direction (CD) is perpendicular to the machine direction and influences the widthwise properties of the finished product, such as tear resistance and dimensional stability. Understanding the differences between MD and CD is crucial for optimizing manufacturing parameters and ensuring consistent material performance in applications like paper, film, and textile production.

Importance of MD and CD in Manufacturing

Machine direction (MD) and cross direction (CD) are critical in manufacturing processes as they determine the mechanical properties and behavior of materials like paper, textiles, and films. Understanding the differences between MD and CD allows you to optimize product strength, flexibility, and dimensional stability by aligning manufacturing techniques with the material's stress orientation. Precise control over MD and CD ensures enhanced performance, quality consistency, and reduced waste in production lines.

Differences Between MD and CD Properties

Machine direction (MD) refers to the orientation parallel to the production flow in manufacturing processes such as paper or fabric production, while cross direction (CD) is perpendicular to MD. MD properties typically exhibit higher tensile strength and elongation due to fiber alignment and continuous stress during processing, whereas CD properties generally show lower strength but greater dimensional stability and tear resistance. Understanding the differences between MD and CD properties is crucial for optimizing product performance in applications like packaging, textiles, and printing.

Factors Influencing MD vs CD Characteristics

Factors influencing machine direction (MD) versus cross direction (CD) characteristics include fiber orientation, production speed, and drying conditions, which impact tensile strength and stretch properties. Fiber alignment along the machine direction results from the papermaking process, enhancing stiffness and resistance parallel to the flow, while fibers in the cross direction contribute to dimensional stability and tear resistance. Understanding these factors helps optimize product performance for your specific application needs.

MD vs CD in Paper and Film Production

Machine Direction (MD) and Cross Direction (CD) represent two principal orientations in paper and film production, impacting mechanical properties and processing behavior. MD aligns with the machine's roller movement, offering greater tensile strength and stiffness, while CD runs perpendicular, providing better dimensional stability and tear resistance. Understanding the balance between MD and CD properties helps you optimize product performance and manufacturing efficiency.

Impact on Product Performance: MD vs CD

Machine direction (MD) aligns with the flow of fibers or materials during manufacturing, resulting in higher tensile strength and stiffness along this axis, which enhances product durability and resistance to elongation. Cross direction (CD), perpendicular to MD, generally exhibits lower tensile strength but offers improved tear resistance and flexibility, influencing product performance in applications requiring multidirectional strength. Understanding the balance between MD and CD properties is crucial for optimizing material selection in packaging, textiles, and paper products to meet specific mechanical and functional requirements.

Testing Methods for MD and CD Strength

Testing methods for Machine Direction (MD) and Cross Direction (CD) strength typically involve tensile strength tests and tearing resistance evaluations. MD strength tests assess the material's ability to withstand forces parallel to the manufacturing process, usually performed using strip tests aligned with the machine direction. CD strength evaluations focus on forces perpendicular to the machine flow, often measured through cross-machine direction strip tests or Elmendorf tearing methods to ensure Your product's durability and quality meet industry standards.

Applications and Industries Affected by MD vs CD

Machine direction (MD) and cross direction (CD) significantly influence material properties in industries such as paper manufacturing, textile production, and plastic film extrusion. MD controls longitudinal strength and stiffness, crucial for applications requiring high tensile strength along the production line, while CD governs transverse characteristics, essential for dimensional stability and flexibility in packaging and labeling. Understanding MD vs CD behavior is vital for optimizing product performance in sectors like printing, converting, and composite materials.

Best Practices for Managing MD and CD Alignment

Ensuring optimal machine direction (MD) and cross direction (CD) alignment requires precise monitoring using advanced sensors to detect tension variations and dimensional changes in real time. Implementing automated control systems can adjust tension and speed dynamically, minimizing web breaks and improving product uniformity. Your production efficiency benefits significantly from regular calibration and consistent maintenance of alignment equipment, preventing costly defects and downtime.

Machine direction vs cross direction (MD vs CD) Infographic

libmatt.com

libmatt.com