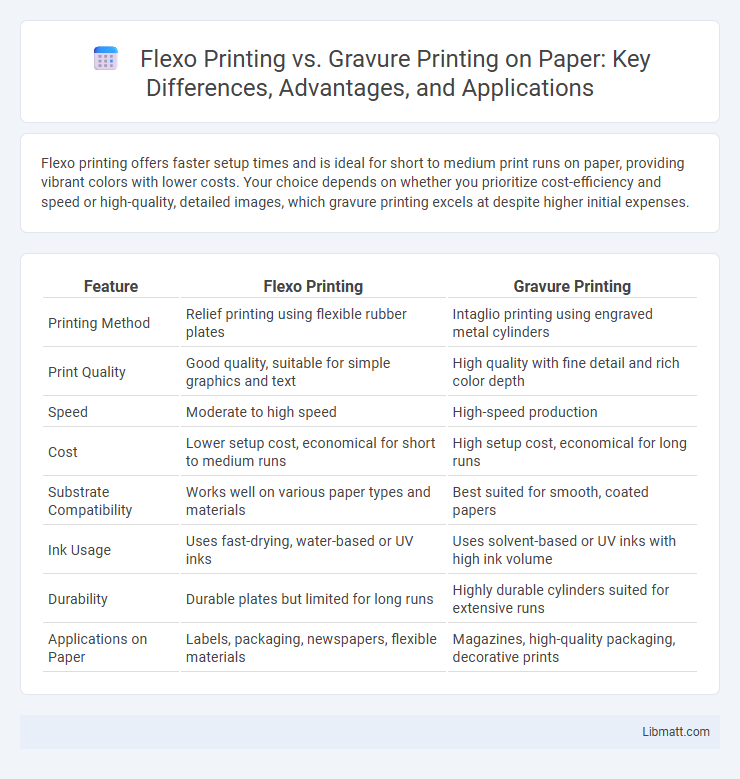

Flexo printing offers faster setup times and is ideal for short to medium print runs on paper, providing vibrant colors with lower costs. Your choice depends on whether you prioritize cost-efficiency and speed or high-quality, detailed images, which gravure printing excels at despite higher initial expenses.

Table of Comparison

| Feature | Flexo Printing | Gravure Printing |

|---|---|---|

| Printing Method | Relief printing using flexible rubber plates | Intaglio printing using engraved metal cylinders |

| Print Quality | Good quality, suitable for simple graphics and text | High quality with fine detail and rich color depth |

| Speed | Moderate to high speed | High-speed production |

| Cost | Lower setup cost, economical for short to medium runs | High setup cost, economical for long runs |

| Substrate Compatibility | Works well on various paper types and materials | Best suited for smooth, coated papers |

| Ink Usage | Uses fast-drying, water-based or UV inks | Uses solvent-based or UV inks with high ink volume |

| Durability | Durable plates but limited for long runs | Highly durable cylinders suited for extensive runs |

| Applications on Paper | Labels, packaging, newspapers, flexible materials | Magazines, high-quality packaging, decorative prints |

Introduction to Flexo and Gravure Printing

Flexo printing utilizes flexible relief plates and fast-drying inks, making it ideal for high-speed production on various paper types with consistent quality. Gravure printing employs engraved cylinders to transfer ink, offering superior image detail and color depth, especially suited for long print runs on smooth paper surfaces. Both methods excel in different applications, with flexo favored for packaging and labels, while gravure is preferred for magazines and high-volume publications.

Printing Process Overview: Flexo vs Gravure

Flexo printing uses flexible relief plates and fast-drying inks to transfer images onto paper, making it ideal for high-speed production runs and packaging materials. Gravure printing employs engraved cylinders to etched cells filled with ink, producing high-resolution images with excellent detail and consistency, especially for long-term, large-volume print jobs. Both processes differ in plate preparation and ink application, affecting print quality, cost, and suitable paper types.

Equipment and Technology Comparison

Flexo printing uses flexible relief plates and fast-drying inks, making it ideal for high-speed production on various paper types with relatively low setup costs. Gravure printing employs engraved cylinders that transfer rich, precise images with superior color depth and fine detail, though it requires more expensive, complex equipment and longer setup times. Your choice depends on balancing initial investment against print quality and production volume, with flexo suited for cost-efficiency and gravure favored for premium, high-resolution paper printing.

Suitable Paper Types for Each Method

Flexo printing is ideal for porous paper types such as kraft paper, paperboard, and coated papers commonly used in packaging and labels due to its flexibility and quick drying inks. Gravure printing excels on smooth, high-quality coated papers and specialty stocks where fine detail and rich color reproduction are essential, often used for magazines and premium packaging. Selecting the appropriate printing method depends on your paper's texture and coating to achieve optimal print quality and durability.

Print Quality and Resolution Differences

Flexo printing typically offers moderate print quality with resolution ranging from 150 to 300 DPI, suitable for large runs of packaging and labels on paper. Gravure printing provides superior print quality with higher resolution capabilities up to 1200 DPI, resulting in sharper images and finer details ideal for high-end paper products. Your choice depends on the desired print clarity and the level of detail required for your specific paper printing project.

Speed and Productivity Analysis

Flexo printing offers higher speed capabilities, reaching up to 1,000 feet per minute, making it suitable for large-volume production runs with quick turnaround times. Gravure printing, while slower at speeds around 500 to 800 feet per minute, delivers superior image quality and consistency, ideal for high-detail and long-duration jobs. Productivity in flexo is enhanced by faster plate changes and setup times, whereas gravure requires longer setup but excels in high-volume runs due to durable engraved cylinders.

Cost Effectiveness: Flexo vs Gravure

Flexo printing offers greater cost-effectiveness for short to medium print runs due to lower plate-making expenses and faster setup times. Gravure printing becomes more economical for high-volume projects, as its durable cylinders reduce per-unit costs over large quantities despite higher initial investment. Your choice should depend on print run length and budget priorities, balancing upfront costs against long-term efficiency.

Environmental Impact and Sustainability

Flexo printing uses water-based inks and consumes less energy, resulting in a lower environmental footprint compared to gravure printing, which relies heavily on solvent-based inks and generates more hazardous waste. Gravure printing involves extensive chemical usage and longer setup times, increasing its environmental impact and making it less sustainable for short to medium runs. Choosing flexo printing for your paper projects supports better sustainability through reduced emissions, less waste, and faster job turnover.

Application Suitability and Market Trends

Flexo printing excels in short to medium runs and is widely used for packaging, labels, and flexible materials due to its fast setup and cost-effectiveness. Gravure printing, preferred for high-volume production on paper, delivers superior image quality and consistency, making it ideal for magazines, catalogs, and premium packaging. Market trends indicate a growing demand for sustainable and eco-friendly inks, with flexo printing adapting quickly to these shifts, while gravure maintains dominance in high-quality, large-scale commercial printing.

Choosing the Right Printing Method for Your Project

Flexo printing excels in cost-effective short to medium runs and quick turnaround times, making it ideal for flexible packaging and labels on paper. Gravure printing offers superior image quality and consistency over long runs, especially for high-volume projects requiring fine detail and vibrant colors. Evaluating your project's print volume, budget, and quality needs will help you determine whether flexo or gravure printing is the best choice for your paper printing requirements.

Flexo printing vs gravure printing (on paper) Infographic

libmatt.com

libmatt.com