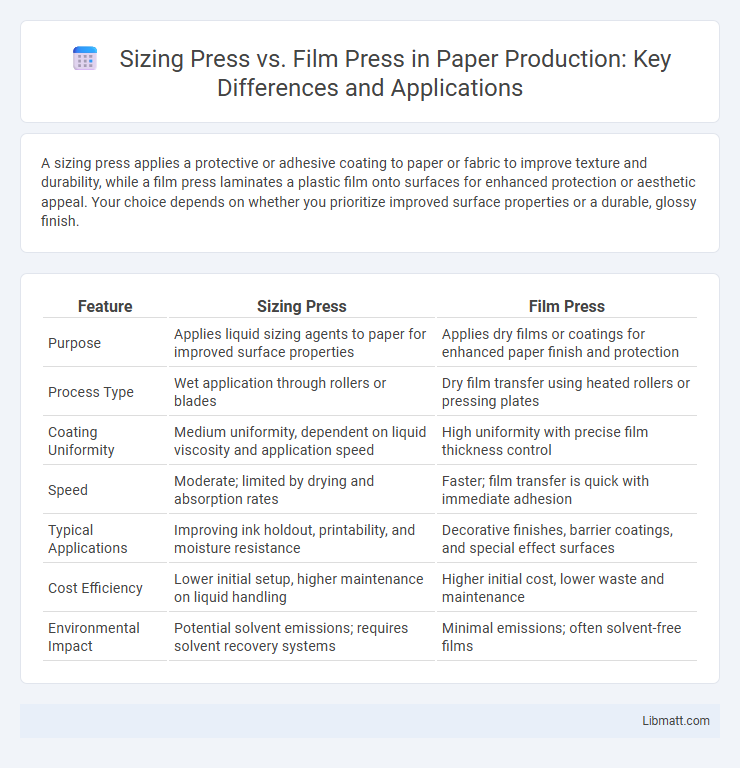

A sizing press applies a protective or adhesive coating to paper or fabric to improve texture and durability, while a film press laminates a plastic film onto surfaces for enhanced protection or aesthetic appeal. Your choice depends on whether you prioritize improved surface properties or a durable, glossy finish.

Table of Comparison

| Feature | Sizing Press | Film Press |

|---|---|---|

| Purpose | Applies liquid sizing agents to paper for improved surface properties | Applies dry films or coatings for enhanced paper finish and protection |

| Process Type | Wet application through rollers or blades | Dry film transfer using heated rollers or pressing plates |

| Coating Uniformity | Medium uniformity, dependent on liquid viscosity and application speed | High uniformity with precise film thickness control |

| Speed | Moderate; limited by drying and absorption rates | Faster; film transfer is quick with immediate adhesion |

| Typical Applications | Improving ink holdout, printability, and moisture resistance | Decorative finishes, barrier coatings, and special effect surfaces |

| Cost Efficiency | Lower initial setup, higher maintenance on liquid handling | Higher initial cost, lower waste and maintenance |

| Environmental Impact | Potential solvent emissions; requires solvent recovery systems | Minimal emissions; often solvent-free films |

Introduction to Sizing Press and Film Press

Sizing press applies a controlled amount of liquid sizing agent onto paper or textile surfaces to enhance strength and smoothness, optimizing material properties for further processing. Film press uses a thin polymer film that bonds to substrates under heat and pressure, creating a protective or functional layer that improves durability and appearance. Both presses are critical in manufacturing, yet they differ in methodology: sizing press emphasizes liquid absorption while film press focuses on surface lamination.

Definition and Basic Operation of Sizing Press

A sizing press is a machine used to apply a protective coating or adhesive layer on textiles or paper to enhance strength and surface properties. It operates by passing the material through rollers that evenly distribute the sizing agent, ensuring consistent absorption and film formation. In contrast, a film press mainly focuses on laminating or bonding films onto substrates, often employing heat and pressure without the application of liquid sizing agents.

Definition and Basic Operation of Film Press

A film press is a specialized machine designed to laminate or bond thin plastic films onto various substrates using heat and pressure, ensuring uniform adhesion and surface finish. Unlike sizing presses that evenly coat paper or textiles with liquid solutions to enhance surface properties, film presses operate by feeding films through heated rollers to achieve precise lamination. The process in a film press involves controlled temperature, pressure, and speed settings to optimize film adhesion and prevent defects such as bubbles or wrinkles.

Key Differences Between Sizing Press and Film Press

Sizing press applies a liquid starch or sizing agent onto fabric to improve strength and surface smoothness, while film press involves laminating a thin polymer film onto textile to enhance durability and provide specific functional properties. Sizing press primarily targets yarn or fabric preparation before weaving or finishing, whereas film press is used post-production for adding protective or decorative layers. Your choice depends on whether the goal is fiber reinforcement or surface modification through polymer lamination.

Applications and Uses of Sizing Press

Sizing presses are primarily used in textile manufacturing to apply a protective adhesive coating to warp yarns, enhancing their strength and abrasion resistance before weaving. This process improves fabric quality by reducing breakage and ensuring smoother weaving operations. Your production efficiency benefits as sizing presses enable better yarn handling, whereas film presses are typically applied in laminating thin plastic films onto substrates for packaging or labeling purposes.

Applications and Uses of Film Press

Film presses are primarily used in packaging industries to laminate films onto various substrates, enhancing product durability and appearance. Unlike sizing presses that treat fabrics to improve texture and strength, film presses specialize in bonding plastic films for applications such as food packaging, labels, and protective covers. Your choice of a film press can significantly impact the efficiency and quality of film lamination in high-volume manufacturing processes.

Advantages of Sizing Press Over Film Press

Sizing press offers superior moisture control and consistent application of sizing agents, resulting in enhanced fabric strength and improved surface smoothness compared to film press. It reduces chemical consumption and processing time by evenly distributing sizing chemicals directly onto the fabric, minimizing waste. The technology also supports better fabric breathability and higher productivity, making it advantageous for large-scale textile manufacturing.

Advantages of Film Press Over Sizing Press

Film press offers enhanced precision and uniformity in coating applications compared to sizing press, enabling consistent film thickness and minimizing material waste. It supports a broader range of coating materials and formulations, providing better control over product properties such as gloss, adhesion, and barrier performance. Film press technology also reduces drying time and energy consumption, leading to increased production efficiency and cost savings in industrial processes.

Factors to Consider When Choosing Between Sizing Press and Film Press

When choosing between a sizing press and a film press, key factors include the type of substrates being processed, desired film thickness, and production speed. Sizing presses are ideal for applying liquid coatings with high penetration on porous materials, while film presses excel in producing uniform, precise polymer films on various substrates. Consider equipment maintenance requirements, process consistency, and cost-effectiveness aligned with specific industrial applications to optimize performance.

Future Trends in Sizing Press and Film Press Technology

Future trends in sizing press and film press technology emphasize increased automation and integration of AI-driven quality control systems to enhance fabric treatment precision and efficiency. Advancements in eco-friendly materials and energy-efficient machinery are driving sustainable production practices, reducing environmental impact. Emerging developments include real-time monitoring sensors and adaptive control mechanisms that optimize chemical application and drying processes for superior fabric performance and reduced waste.

Sizing press vs film press Infographic

libmatt.com

libmatt.com