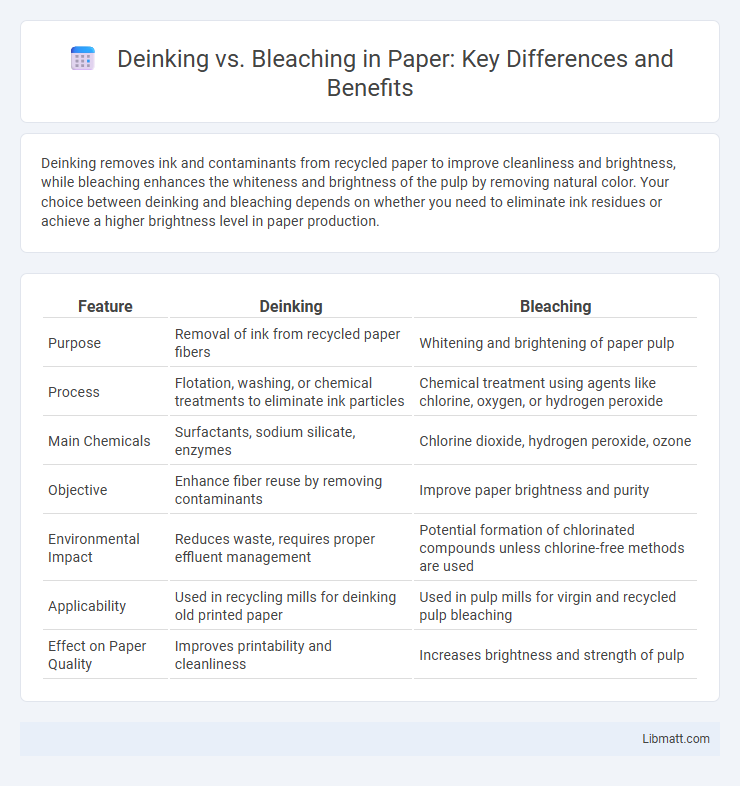

Deinking removes ink and contaminants from recycled paper to improve cleanliness and brightness, while bleaching enhances the whiteness and brightness of the pulp by removing natural color. Your choice between deinking and bleaching depends on whether you need to eliminate ink residues or achieve a higher brightness level in paper production.

Table of Comparison

| Feature | Deinking | Bleaching |

|---|---|---|

| Purpose | Removal of ink from recycled paper fibers | Whitening and brightening of paper pulp |

| Process | Flotation, washing, or chemical treatments to eliminate ink particles | Chemical treatment using agents like chlorine, oxygen, or hydrogen peroxide |

| Main Chemicals | Surfactants, sodium silicate, enzymes | Chlorine dioxide, hydrogen peroxide, ozone |

| Objective | Enhance fiber reuse by removing contaminants | Improve paper brightness and purity |

| Environmental Impact | Reduces waste, requires proper effluent management | Potential formation of chlorinated compounds unless chlorine-free methods are used |

| Applicability | Used in recycling mills for deinking old printed paper | Used in pulp mills for virgin and recycled pulp bleaching |

| Effect on Paper Quality | Improves printability and cleanliness | Increases brightness and strength of pulp |

Introduction to Deinking and Bleaching

Deinking removes inks and contaminants from recycled paper fibers to produce cleaner pulp, essential in paper recycling processes. Bleaching enhances the brightness and whiteness of pulp by chemically treating it, improving the paper's visual and quality standards. Both deinking and bleaching optimize pulp quality, balancing environmental impact with manufacturing efficiency.

Understanding the Purpose of Deinking

Deinking is a critical process in paper recycling that removes ink, adhesives, and other contaminants from printed paper fibers to produce clean pulp suitable for reuse. Unlike bleaching, which primarily enhances whiteness and brightness by chemically altering fiber color, deinking focuses on ink particle separation to maintain fiber strength and quality. Understanding the purpose of deinking helps you optimize recycled paper production by ensuring a cleaner, higher-quality pulp before any bleaching treatments.

The Role of Bleaching in Pulp and Paper Industry

Bleaching plays a crucial role in the pulp and paper industry by enhancing the brightness and purity of pulp fibers, which directly impacts the quality of the final paper product. Unlike deinking, which primarily removes ink particles from recycled paper to facilitate repulping, bleaching chemically alters pulp to remove lignin and other impurities, resulting in whiter, more durable paper. Your choice between bleaching and deinking depends on whether you are processing virgin pulp or recycled fibers for optimal paper production efficiency and quality.

Key Differences Between Deinking and Bleaching

Deinking primarily removes ink and contaminants from recycled paper fibers, enhancing pulp cleanliness and print quality, while bleaching focuses on brightening pulp by eliminating residual lignin and other color-causing substances to achieve high whiteness levels. Deinking involves processes like flotation, washing, and enzymatic treatments tailored to ink particle separation, whereas bleaching employs chemical agents such as chlorine dioxide, oxygen, or hydrogen peroxide to improve brightness without necessarily altering fiber purity. The key difference lies in deinking's role in recycled fiber preparation for reuse, contrasted with bleaching's goal of enhancing pulp whiteness in both virgin and recycled materials.

Common Methods Used in Deinking

Common methods used in deinking include flotation, washing, and enzymatic treatments, each targeting the removal of ink particles from recycled paper fibers. Flotation relies on injecting air bubbles that attach to hydrophobic ink particles, lifting them to the surface for removal. Washing employs water and mechanical agitation to detach and wash away ink, while enzymatic treatments use specific enzymes to break down ink binders, enhancing deinking efficiency.

Popular Bleaching Techniques Explained

Popular bleaching techniques include chlorine bleaching, oxygen-based bleaching, and enzymatic bleaching, each offering unique benefits for pulp whitening. Chlorine bleaching uses chlorine or chlorine dioxide for effective lignin removal, while oxygen-based methods like hydrogen peroxide reduce environmental impact by avoiding harmful byproducts. Your choice of bleaching technique affects the paper's brightness, strength, and sustainability, making it essential to balance performance with eco-friendly practices.

Environmental Impact: Deinking vs Bleaching

Deinking significantly reduces environmental impact by recycling paper fibers, lowering the need for virgin pulp and minimizing deforestation. Bleaching, especially with chlorine-based chemicals, generates harmful byproducts like dioxins, which contribute to water pollution and ecosystem damage. Choosing deinking over traditional bleaching methods supports sustainable papermaking and reduces the carbon footprint associated with paper production.

Technological Advances in Deinking and Bleaching

Technological advances in deinking have introduced enzymatic treatments and ultrasonic processes that effectively remove inks from recycled paper fibers while preserving fiber quality. Bleaching technology has progressed with the adoption of oxygen-based and chlorine-free methods, such as hydrogen peroxide and ozone bleaching, reducing environmental impact and enhancing pulp brightness. You can now benefit from these innovations to achieve higher quality recycled paper products with improved environmental sustainability.

Cost Comparison: Deinking vs Bleaching

Deinking generally offers a cost-effective solution compared to bleaching, as it requires less chemical usage and energy consumption during the paper recycling process. Bleaching, while providing a higher brightness level, often involves expensive chemicals like chlorine or hydrogen peroxide, increasing operational expenses. Your choice between deinking and bleaching should consider the balance between cost efficiency and the desired quality of the recycled paper.

Future Trends in Paper Recycling and Whitening

Future trends in paper recycling and whitening emphasize sustainable methods such as enzymatic deinking and oxygen-based bleaching, which reduce environmental impact while maintaining high paper quality. Innovative technologies like nanotechnology and bio-bleaching agents are emerging to enhance fiber recovery and whiteness without harsh chemicals. Your choice of recycled paper products will increasingly benefit from these eco-friendly advancements, promoting greener production in the paper industry.

Deinking vs bleaching Infographic

libmatt.com

libmatt.com