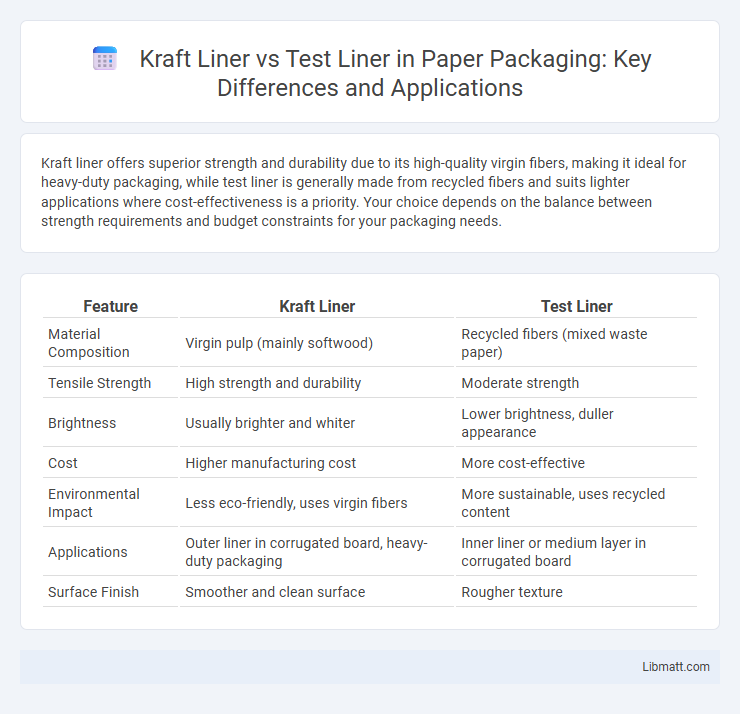

Kraft liner offers superior strength and durability due to its high-quality virgin fibers, making it ideal for heavy-duty packaging, while test liner is generally made from recycled fibers and suits lighter applications where cost-effectiveness is a priority. Your choice depends on the balance between strength requirements and budget constraints for your packaging needs.

Table of Comparison

| Feature | Kraft Liner | Test Liner |

|---|---|---|

| Material Composition | Virgin pulp (mainly softwood) | Recycled fibers (mixed waste paper) |

| Tensile Strength | High strength and durability | Moderate strength |

| Brightness | Usually brighter and whiter | Lower brightness, duller appearance |

| Cost | Higher manufacturing cost | More cost-effective |

| Environmental Impact | Less eco-friendly, uses virgin fibers | More sustainable, uses recycled content |

| Applications | Outer liner in corrugated board, heavy-duty packaging | Inner liner or medium layer in corrugated board |

| Surface Finish | Smoother and clean surface | Rougher texture |

Introduction to Kraft Liner and Test Liner

Kraft liner is a high-quality paperboard made from virgin wood fibers known for its superior strength and durability, commonly used in packaging applications requiring toughness. Test liner is a recycled paperboard produced primarily from recovered fibers, offering an economical and sustainable option with decent stiffness for everyday packaging needs. Your choice between kraft liner and test liner depends on the balance of strength, environmental impact, and cost efficiency required for your specific project.

What is Kraft Liner?

Kraft liner is a high-strength paperboard used primarily as the outer layer in corrugated cardboard, made from virgin kraft pulp that provides superior durability and resistance to moisture. It offers excellent tensile strength, making it ideal for packaging applications that require robust protection and stacking strength. Your packaging solutions benefit from kraft liner's ability to maintain integrity under heavy loads and rough handling.

What is Test Liner?

Test liner is a type of paperboard made primarily from recycled fibers, used mainly for the outer layers of corrugated cardboard. It offers moderate strength and surface quality compared to kraft liner, making it suitable for packaging that requires cost-effective, eco-friendly materials. Test liner's recycled content enhances sustainability but generally results in lower durability and moisture resistance than virgin fiber kraft liner.

Key Differences Between Kraft Liner and Test Liner

Kraft liner is produced from virgin wood fibers, offering superior strength, durability, and resistance to moisture, making it ideal for heavy-duty packaging applications. Test liner, on the other hand, is made primarily from recycled fibers, providing a more economical and environmentally friendly option with moderate strength and printability. The key differences lie in the fiber composition, with kraft liner providing higher tensile strength and stiffness, while test liner emphasizes sustainability and cost-effectiveness for less demanding uses.

Raw Materials and Composition

Kraft liner primarily consists of virgin fibers derived from softwood pulp, offering superior strength and durability due to its long fibers and high-quality chemical treatment. Test liner, on the other hand, is made from a combination of recycled fibers and recovered paper, resulting in a cost-effective but less durable material compared to kraft liner. Your choice between kraft liner and test liner depends on the balance between required strength and budget constraints in packaging applications.

Strength and Durability Comparison

Kraft liner offers superior strength and durability due to its high-quality virgin fibers, making it ideal for heavy-duty packaging and demanding applications. Test liner, typically composed of recycled fibers, provides moderate strength suited for lightweight or less critical uses but is more prone to wear and tear over time. Your choice between kraft liner and test liner should depend on the packaging requirements, balancing cost efficiency with the need for robust performance.

Environmental Impact and Sustainability

Kraft liner demonstrates a lower environmental impact due to its higher strength and durability, which reduces the need for frequent replacements and supports efficient recycling processes. Test liner, while often made from recycled fibers, may have a higher environmental footprint because its lower performance can lead to increased material consumption and reduced longevity. Sustainable packaging solutions favor kraft liner for its superior fiber quality, enhanced recyclability, and contribution to circular economy goals.

Cost Comparison: Kraft Liner vs Test Liner

Kraft liner typically incurs higher production costs due to its superior strength and durability derived from virgin wood fibers, making it more expensive than test liner, which is primarily made from recycled fibers. Test liner offers a cost-efficient alternative with acceptable performance for applications requiring moderate strength, significantly reducing material expenses. Businesses prioritize kraft liner when durability and performance justify the investment, while test liner is favored for budget-conscious projects demanding lower-cost linerboard options.

Common Uses and Applications

Kraft liner is commonly used as the outermost layer in corrugated cardboard boxes due to its high strength, durability, and excellent resistance to tearing and punctures, making it ideal for packaging heavy or fragile items. Test liner is typically employed for the inner layers or as a middle ply in corrugated board because it offers good compressive strength at a lower cost, suitable for general packaging and cartons. Your choice between kraft liner and test liner depends on the specific packaging requirements, including durability, appearance, and budget constraints.

Which Liner is Best for Your Packaging Needs?

Kraft liner offers superior strength and durability, making it ideal for heavy-duty packaging requiring high load-bearing capacity and resistance to tearing. Test liner provides a cost-effective alternative with moderate strength, suitable for lighter packaging applications where budget considerations are key. Assess Your packaging requirements for weight, protection, and budget to determine whether kraft liner or test liner best meets Your needs.

kraft liner vs test liner Infographic

libmatt.com

libmatt.com