Yankee dryers provide efficient drying with a large heated cylinder used primarily in tissue and paper production, offering excellent steam heat transfer and uniform drying. Your choice between a Yankee dryer and an MG cylinder depends on factors like production speed, sheet quality, and moisture content requirements.

Table of Comparison

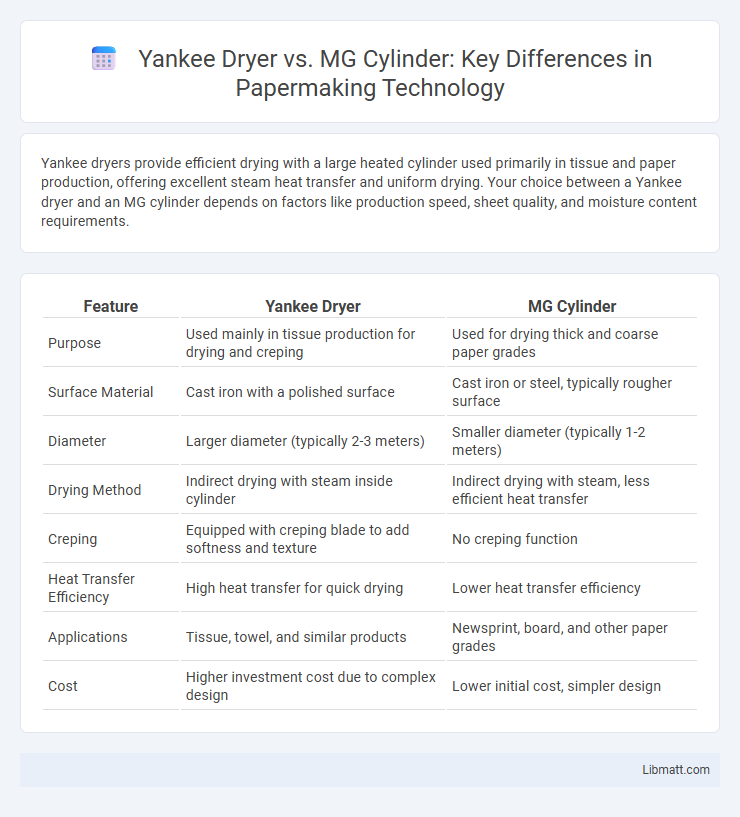

| Feature | Yankee Dryer | MG Cylinder |

|---|---|---|

| Purpose | Used mainly in tissue production for drying and creping | Used for drying thick and coarse paper grades |

| Surface Material | Cast iron with a polished surface | Cast iron or steel, typically rougher surface |

| Diameter | Larger diameter (typically 2-3 meters) | Smaller diameter (typically 1-2 meters) |

| Drying Method | Indirect drying with steam inside cylinder | Indirect drying with steam, less efficient heat transfer |

| Creping | Equipped with creping blade to add softness and texture | No creping function |

| Heat Transfer Efficiency | High heat transfer for quick drying | Lower heat transfer efficiency |

| Applications | Tissue, towel, and similar products | Newsprint, board, and other paper grades |

| Cost | Higher investment cost due to complex design | Lower initial cost, simpler design |

Introduction to Yankee Dryer and MG Cylinder

Yankee dryers and MG cylinders are essential components in paper production, specifically in the drying process of tissue and paper webs. The Yankee dryer is a large, heated steel cylinder used primarily in tissue manufacturing to dry and crepe the paper, enhancing softness and bulk. MG cylinders, or machine glazed cylinders, produce a smoother surface finish by drying paper webs against a polished surface, improving printability and appearance in graphic papers.

Key Differences Between Yankee Dryer and MG Cylinder

Yankee dryers feature a large, steam-heated cast iron or steel cylinder used primarily in tissue production for high-speed drying and creping, while MG cylinders are smaller, specially designed drying cylinders integrated into the Multi-Grade (MG) paper machine for enhanced moisture control and surface smoothness. Yankee dryers provide superior creping and drying efficiency due to their larger diameter and steam capacity, whereas MG cylinders focus on improving paper quality and uniform drying in the final product. The operational temperature, drying surface area, and functional role in the paper machine cycle distinctly separate Yankee dryers from MG cylinders, influencing both production speed and paper characteristics.

Working Principles of Yankee Dryers

Yankee dryers operate by directing steam into a large, rotating cast iron cylinder, which transfers heat to the paper web pressed against its surface, effectively evaporating moisture during tissue production. The MG (Metallized Gas) cylinder, unlike the Yankee, relies on a metal-coated drum heated indirectly through internal steam channels that enhance thermal conductivity and drying efficiency. Both technologies optimize drying through contact with heated rotating surfaces, but Yankee dryers are specifically designed for high-speed creping, improving sheet softness and bulk.

Mechanism of MG Cylinders

MG cylinders operate through a steam-heated drum mechanism that efficiently removes moisture from paper by transferring heat via conduction and convection. The cylinder surface, typically coated with a high-quality cast iron, provides consistent steam distribution and thermal stability, enhancing drying uniformity and speed. Unlike Yankee dryers, MG cylinders deliver superior temperature control and energy efficiency due to their robust steam chest design that minimizes heat loss during the drying process.

Applications in Paper Manufacturing

Yankee dryers and MG cylinders serve distinct roles in paper manufacturing, with Yankee dryers primarily used for drying tissue and towel grades requiring high moisture removal and creping capabilities. MG cylinders, or machine glaze cylinders, enhance the surface smoothness and gloss of paper, making them essential for producing coated and uncoated graphic papers. The choice between Yankee dryers and MG cylinders depends on the desired paper quality, with Yankee dryers favored for softness and bulk, while MG cylinders target surface finish and printability.

Advantages of Yankee Dryer Technology

Yankee dryer technology offers superior energy efficiency by directly drying tissue webs through a large, steam-heated cylinder, resulting in faster production speeds and enhanced paper softness compared to MG cylinders. Its creping process improves bulk and absorbency, creating a premium quality tissue product ideal for consumer comfort. By choosing a Yankee dryer, your operation benefits from reduced steam consumption and improved drying capacity, optimizing overall manufacturing performance.

Benefits of Using MG Cylinders

MG cylinders offer superior drying efficiency compared to Yankee dryers by providing a larger heated surface area, which accelerates moisture removal from paper webs. They enhance energy savings due to lower steam pressure requirements and reduced heat loss, making your paper production process more cost-effective. MG cylinders also improve sheet quality by delivering uniform drying, minimizing defects like curl and brittleness.

Performance Comparison: Yankee Dryer vs MG Cylinder

Yankee dryers offer superior drying efficiency with high thermal transfer rates due to their large heated surface, making them ideal for tissue paper production. MG cylinders, while providing slower drying speeds, deliver more uniform heat distribution for better sheet quality in applications like fine paper and linerboard. Your choice depends on balancing the need for speed versus the desired product finish in the paper manufacturing process.

Cost and Energy Efficiency Analysis

Yankee dryers generally have higher initial costs but offer superior energy efficiency by effectively condensing steam and recycling heat, reducing overall energy consumption in paper drying processes. MG cylinders often require lower upfront investment but tend to consume more energy due to less effective heat transfer and condensation systems. Understanding your specific production needs will help determine which drying technology balances cost and energy efficiency for optimal operational savings.

Factors to Consider When Choosing Between Yankee Dryer and MG Cylinder

When choosing between a Yankee dryer and an MG cylinder, key factors include drying capacity, energy efficiency, and product quality requirements. Yankee dryers excel in high-speed tissue drying with superior creping capabilities, enhancing softness and bulk, while MG cylinders offer greater versatility in drying fabrics with uniform heat distribution. Operational costs, maintenance complexity, and compatibility with existing machinery should also influence the decision to optimize production efficiency and end-product characteristics.

Yankee dryer vs MG cylinder Infographic

libmatt.com

libmatt.com