Melamine paper offers a decorative and durable surface commonly used for furniture and cabinetry, while phenolic paper provides superior resistance to moisture, heat, and chemicals, making it ideal for industrial applications and laminate countertops. Your choice depends on whether aesthetics or enhanced durability in harsh conditions is the priority.

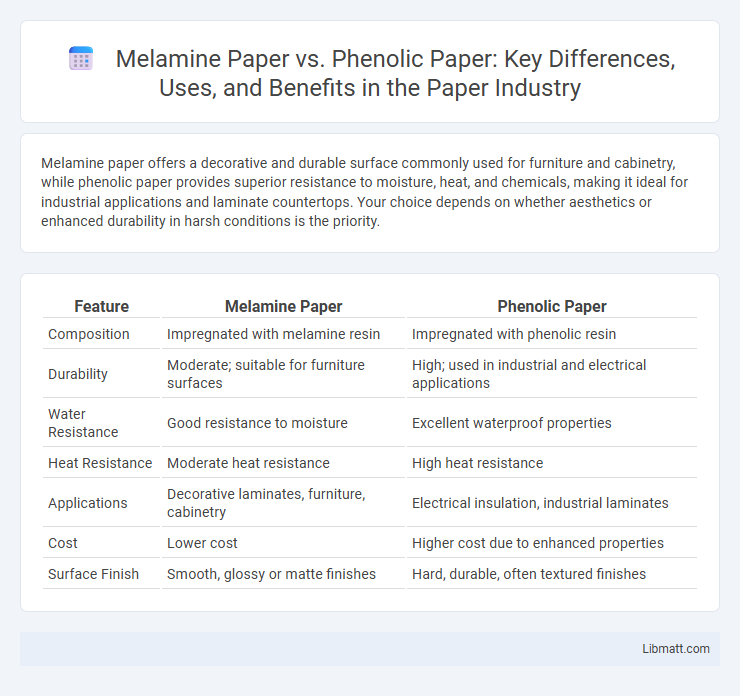

Table of Comparison

| Feature | Melamine Paper | Phenolic Paper |

|---|---|---|

| Composition | Impregnated with melamine resin | Impregnated with phenolic resin |

| Durability | Moderate; suitable for furniture surfaces | High; used in industrial and electrical applications |

| Water Resistance | Good resistance to moisture | Excellent waterproof properties |

| Heat Resistance | Moderate heat resistance | High heat resistance |

| Applications | Decorative laminates, furniture, cabinetry | Electrical insulation, industrial laminates |

| Cost | Lower cost | Higher cost due to enhanced properties |

| Surface Finish | Smooth, glossy or matte finishes | Hard, durable, often textured finishes |

Introduction to Melamine Paper and Phenolic Paper

Melamine paper is a decorative surface material impregnated with melamine resin, known for its smooth texture and resistance to scratches and stains, commonly used in furniture and laminate flooring. Phenolic paper, on the other hand, is a high-strength composite material made by saturating paper with phenolic resin, offering superior durability, heat resistance, and chemical stability, often utilized in industrial and electrical applications. Both materials serve distinct purposes, with melamine paper emphasizing aesthetic appeal and phenolic paper prioritizing structural resilience.

What is Melamine Paper?

Melamine paper is a decorative overlay impregnated with melamine resin, widely used in furniture and cabinetry for its durability and resistance to scratches and stains. This paper undergoes a high-pressure, high-temperature curing process to create a hard, protective surface that maintains color and pattern integrity over time. You can expect melamine paper to provide an affordable, aesthetically pleasing finish compared to phenolic paper, which offers superior strength for industrial applications.

What is Phenolic Paper?

Phenolic paper is a high-pressure laminate composed of cellulose fibers impregnated with phenolic resin, known for its exceptional durability, heat resistance, and moisture resistance. It is widely used in industrial applications such as countertops, electrical insulation, and exterior cladding due to its strong mechanical properties and chemical stability. When choosing between melamine paper and phenolic paper, your decision should consider phenolic paper's superior strength and longevity in demanding environments.

Key Differences Between Melamine and Phenolic Paper

Melamine paper features a decorative layer impregnated with melamine resin, ideal for surfaces like furniture and cabinetry, offering moderate durability and resistance to scratches. Phenolic paper is impregnated with phenolic resin, resulting in a tougher, more heat-resistant material suited for industrial applications such as countertops and laboratory work surfaces. You should choose melamine paper for aesthetic appeal and cost-effectiveness, while phenolic paper excels in strength, moisture resistance, and long-term performance.

Manufacturing Processes Compared

Melamine paper is produced by impregnating paper with melamine resin and curing it under heat and pressure, resulting in a durable, decorative surface commonly used in laminates and furniture. Phenolic paper involves soaking paper sheets in phenolic resin followed by a pressing process at high temperature and pressure, creating a robust, heat-resistant material ideal for industrial applications. Your choice depends on the desired strength, durability, and application environment, as phenolic paper offers higher mechanical and chemical resistance compared to melamine paper.

Strength and Durability: Melamine vs Phenolic

Phenolic paper exhibits superior strength and durability compared to melamine paper due to its higher resin content and enhanced resistance to impact, moisture, and heat. Melamine paper, while durable for decorative surfaces, is more prone to wear and less resistant to chemicals and abrasion. Phenolic paper's robust structure makes it ideal for heavy-duty applications requiring long-term performance and structural integrity.

Applications and Use Cases

Melamine paper is widely used in decorative laminates for furniture, cabinetry, and wall panels due to its high durability and resistance to scratches and stains. Phenolic paper is primarily employed in industrial applications such as electrical insulation, circuit boards, and structural components because of its superior heat resistance and mechanical strength. Both materials offer distinct benefits, with melamine paper excelling in aesthetic surfaces while phenolic paper supports heavy-duty, high-performance requirements.

Cost Comparison: Melamine vs Phenolic Paper

Melamine paper generally offers a lower cost compared to phenolic paper, making it a budget-friendly option for decorative laminates and surface applications. Phenolic paper, with its higher resin content and enhanced durability, commands a premium price but provides superior resistance to heat, chemicals, and wear. When balancing cost against performance, your choice depends on whether budget constraints or long-term durability are the priority.

Environmental Impact and Safety

Melamine paper produces fewer volatile organic compounds (VOCs) during manufacturing, reducing environmental pollution compared to phenolic paper, which relies on phenol-based resins known for their higher toxicity. Phenolic paper poses greater health risks due to formaldehyde emissions, whereas melamine paper offers improved indoor air quality, enhancing safety for Your living or working space. Both materials are durable, but choosing melamine paper supports lower ecological footprint and safer environmental conditions.

Choosing the Right Material for Your Project

Melamine paper offers a budget-friendly option with good scratch resistance and aesthetic versatility, ideal for decorative surfaces in furniture and cabinetry. Phenolic paper provides superior durability, chemical resistance, and heat resistance, making it the preferred choice for heavy-use environments like laboratory countertops and industrial applications. Understanding these material properties helps you select the right paper to ensure lasting performance and visual appeal in your project.

melamine paper vs phenolic paper Infographic

libmatt.com

libmatt.com