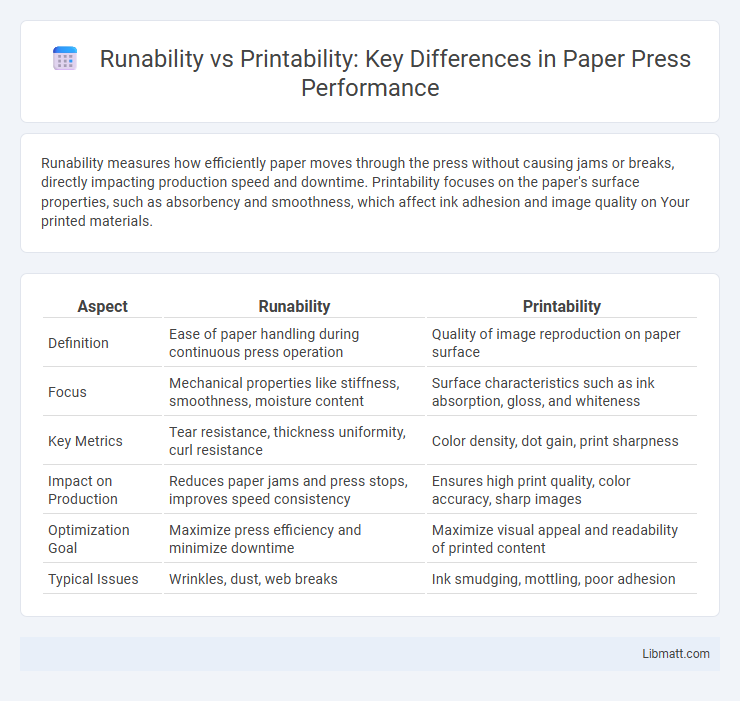

Runability measures how efficiently paper moves through the press without causing jams or breaks, directly impacting production speed and downtime. Printability focuses on the paper's surface properties, such as absorbency and smoothness, which affect ink adhesion and image quality on Your printed materials.

Table of Comparison

| Aspect | Runability | Printability |

|---|---|---|

| Definition | Ease of paper handling during continuous press operation | Quality of image reproduction on paper surface |

| Focus | Mechanical properties like stiffness, smoothness, moisture content | Surface characteristics such as ink absorption, gloss, and whiteness |

| Key Metrics | Tear resistance, thickness uniformity, curl resistance | Color density, dot gain, print sharpness |

| Impact on Production | Reduces paper jams and press stops, improves speed consistency | Ensures high print quality, color accuracy, sharp images |

| Optimization Goal | Maximize press efficiency and minimize downtime | Maximize visual appeal and readability of printed content |

| Typical Issues | Wrinkles, dust, web breaks | Ink smudging, mottling, poor adhesion |

Understanding Runability in Paper Press Operations

Runability in paper press operations refers to the ease and efficiency with which paper travels through the press without causing stoppages or defects, directly impacting production speed and quality. Unlike printability, which focuses on how well the paper accepts ink and produces clear images, runability emphasizes mechanical performance and consistency during high-speed runs. Your knowledge of runability helps optimize operational efficiency by minimizing downtime and maintaining smooth paper feed, essential for maximizing output in industrial printing environments.

Defining Printability for Quality Output

Printability defines the ability of paper to accept ink uniformly, ensuring sharp images and consistent color reproduction on a paper press. Runability relates to the paper's performance during the printing process, including smooth feeding and minimal jams, but printability specifically targets the quality of the final output. Your choice of paper with high printability guarantees clear, vibrant prints and reduces post-press defects, maximizing overall production quality.

Key Factors Affecting Runability

Key factors affecting runability in paper press include paper quality, moisture content, and surface finish, which directly impact machine speed and waste reduction. Proper calibration of press settings and consistent paper tension are essential to maintain smooth operations and minimize downtime. Your ability to control these variables improves runability, ensuring efficient production and optimal printability results.

Essential Elements Influencing Printability

Essential elements influencing printability on a paper press include paper smoothness, ink absorption, and moisture content, each directly impacting the clarity and consistency of printed images. Runability hinges on factors such as tensile strength, thickness, and surface texture, which determine the paper's ability to withstand the mechanical stresses during high-speed press runs. Optimizing these attributes ensures your printing process achieves high-quality outputs without frequent paper breaks or print defects.

Runability vs Printability: Core Differences

Runability in paper press refers to the paper's ability to smoothly pass through the press without causing jams, breaks, or misfeeds, ensuring consistent machine speed and minimal downtime. Printability focuses on the paper's surface properties such as absorbency, smoothness, and ink adhesion, which affect image quality, color accuracy, and drying time. While runability emphasizes mechanical compatibility with the press, printability prioritizes the final print output's clarity and fidelity.

Impact of Substrate Properties on Performance

Substrate properties such as porosity, surface energy, and smoothness significantly influence runability and printability on paper presses. Higher porosity can enhance ink absorption, improving dry time but potentially causing ink spread and reduced image sharpness. Smooth, low-porosity substrates promote precise ink transfer and sharp print quality, but may challenge runability by increasing the risk of paper jams or wrinkles during high-speed presses.

Role of Machine Conditions in Runability

Machine conditions critically influence runability in paper press operations by affecting sheet tension, alignment, and moisture content. Optimal machine settings ensure smooth web handling and reduce breaks, directly enhancing printability by maintaining consistent paper quality. Proper adjustment of dryers, calenders, and press rolls minimizes defects, enabling better ink absorption and sharp image reproduction for Your final printed product.

Importance of Ink-Paper Interaction for Printability

Ink-paper interaction critically influences printability by determining how well ink adheres, spreads, and dries on the paper surface, affecting print quality and durability. Proper runability ensures your press operates smoothly by minimizing ink smudging, set-off, and paper jams caused by suboptimal ink absorption and drying times. Optimizing this interaction enhances color vibrancy, sharpness, and print consistency, essential for high-quality, efficient paper press operations.

Enhancing Both Runability and Printability: Best Practices

Optimizing runability and printability on paper presses requires selecting high-quality substrates with consistent thickness and surface smoothness to reduce sheet breaks and improve ink adhesion. Maintaining precise press calibration, including correct tension settings and ink viscosity, ensures stable paper feed and sharp image reproduction. Regular equipment maintenance combined with real-time monitoring systems minimizes downtime and maximizes both production efficiency and print quality.

Troubleshooting Common Issues in Paper Press Processes

Troubleshooting common issues in paper press processes involves understanding the balance between runability and printability to optimize production efficiency and print quality. Paper with poor runability may cause frequent web breaks, misfeeds, or jamming, while compromised printability can lead to ink smudging, uneven coating, or poor image resolution. You can improve outcomes by selecting papers with suitable surface texture, moisture content, and stiffness that match both press specifications and printing requirements.

Runability vs printability (paper press) Infographic

libmatt.com

libmatt.com