Lightweight coated paper offers a thinner, more flexible feel suitable for high-volume printing and mailing, while mediumweight coated paper provides greater durability and a premium finish ideal for brochures and catalogs. Choosing the right coating weight impacts the tactile experience and longevity of your printed materials.

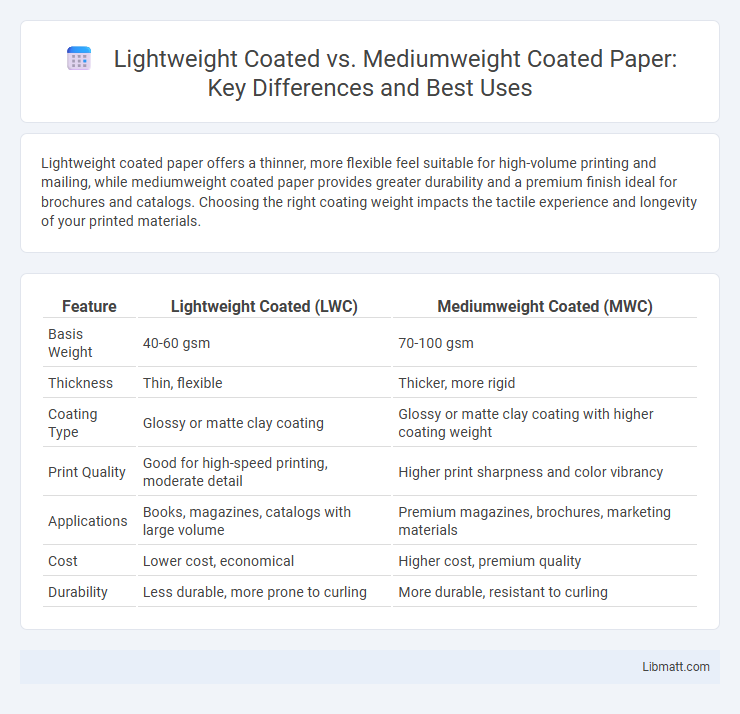

Table of Comparison

| Feature | Lightweight Coated (LWC) | Mediumweight Coated (MWC) |

|---|---|---|

| Basis Weight | 40-60 gsm | 70-100 gsm |

| Thickness | Thin, flexible | Thicker, more rigid |

| Coating Type | Glossy or matte clay coating | Glossy or matte clay coating with higher coating weight |

| Print Quality | Good for high-speed printing, moderate detail | Higher print sharpness and color vibrancy |

| Applications | Books, magazines, catalogs with large volume | Premium magazines, brochures, marketing materials |

| Cost | Lower cost, economical | Higher cost, premium quality |

| Durability | Less durable, more prone to curling | More durable, resistant to curling |

Introduction to Coated Paper Types

Lightweight coated paper typically ranges between 60 to 90 gsm, offering a smooth surface ideal for high-quality printing with reduced bulk, making it perfect for flyers and catalogs. Mediumweight coated paper generally falls between 100 to 150 gsm, providing enhanced durability and a premium feel suitable for brochures, magazines, and presentations. Understanding the differences helps you select the optimal coated paper type for your printing project, balancing quality, texture, and cost-effectiveness.

Defining Lightweight and Mediumweight Coated Papers

Lightweight coated papers typically weigh between 60-90 gsm, offering a thinner, more flexible finish ideal for magazines and catalogs that require high-quality print with reduced bulk. Mediumweight coated papers usually range from 91-130 gsm, providing a sturdier feel with enhanced opacity and durability, making them suitable for brochures and flyers where a balance of quality and substance is essential. Choosing between lightweight and mediumweight coated paper depends on your project's need for portability versus tactile impression.

Key Differences in Thickness and Weight

Lightweight coated paper typically ranges from 50 to 90 gsm, making it thinner and more flexible compared to mediumweight coated paper, which usually falls between 100 to 170 gsm and offers greater durability and heft. The thickness of lightweight coated paper often results in a smoother finish ideal for high-quality printing with less bulk, while mediumweight coated paper provides a sturdier feel suitable for brochures and magazines. Your choice between these two depends on the balance you need between portability and substance for your print projects.

Printing Quality and Image Reproduction

Lightweight coated paper offers smooth surfaces that enhance printing quality with sharp details and vibrant colors, making it ideal for high-volume brochures and flyers. Mediumweight coated paper provides superior opacity and durability, resulting in richer image reproduction with deeper color saturation and better contrast, suitable for premium catalogs and art books. Both types are engineered for offset and digital printing but differ in tactile feel and visual impact based on their coating weight and caliper.

Durability and Resistance to Handling

Lightweight coated paper offers moderate durability, suitable for projects with minimal handling such as flyers and brochures, but it may show wear and tear more quickly under frequent use. Mediumweight coated paper provides enhanced resistance to handling, making it ideal for materials like catalogs, magazines, and annual reports that require more robustness and longer lifespan. Its thicker composition improves resistance to creasing, tearing, and surface damage during extended handling and transport.

Cost Considerations for Lightweight vs Mediumweight

Lightweight coated paper typically costs less than mediumweight coated paper due to lower material usage and reduced manufacturing expenses. Mediumweight coated paper demands higher production costs because of its increased thickness and durability, which can impact overall project budgets. Choosing between lightweight and mediumweight coated paper depends on balancing cost efficiency with the specific requirements for print quality and paper sturdiness.

Environmental Impact and Sustainability

Lightweight coated papers consume fewer raw materials and energy during production, significantly reducing their carbon footprint compared to mediumweight coated papers. They also result in less waste during transportation due to lower weight, leading to decreased greenhouse gas emissions. Mediumweight coated papers, although more durable, often require more resources and energy, making them less favorable for environmentally sustainable printing solutions.

Common Applications in Publishing and Packaging

Lightweight coated paper is primarily used for high-quality magazines, catalogs, and brochures where vibrant color reproduction and smooth finish are essential. Mediumweight coated paper is favored in packaging applications such as folding cartons and labels due to its increased durability and stiffness. Both types support offset and digital printing methods, optimizing visual appeal and functionality based on the intended end use.

Choosing the Right Coated Paper for Your Project

Choosing the right coated paper for your project depends on the balance between durability and print quality you require; lightweight coated paper offers a thinner, more flexible option ideal for flyers and brochures, while mediumweight coated paper provides enhanced sturdiness suited for premium marketing materials and booklets. Your project will benefit from considering factors such as gloss level, opacity, and thickness, where lightweight options promote cost-efficiency and easier handling, and mediumweight papers improve color vibrancy and resistance to wear. Assessing the specific needs of your print job ensures optimal presentation and functionality, guiding your selection between lightweight and mediumweight coated options.

Final Recommendations and Industry Best Practices

Lightweight coated paper, typically ranging from 60 to 90 gsm, is ideal for high-volume printing requiring cost-efficiency and vibrant color reproduction, such as magazines and catalogs. Mediumweight coated paper, usually between 100 to 150 gsm, offers enhanced durability and a premium feel, making it suitable for brochures, flyers, and direct mail pieces demanding higher perceived value. Industry best practices recommend selecting paper weight based on the balance between budget constraints, print quality, and end-use durability, with lightweight coated favored for large-scale runs and mediumweight coated prioritized for marketing materials that benefit from tactile quality.

Lightweight coated vs mediumweight coated Infographic

libmatt.com

libmatt.com