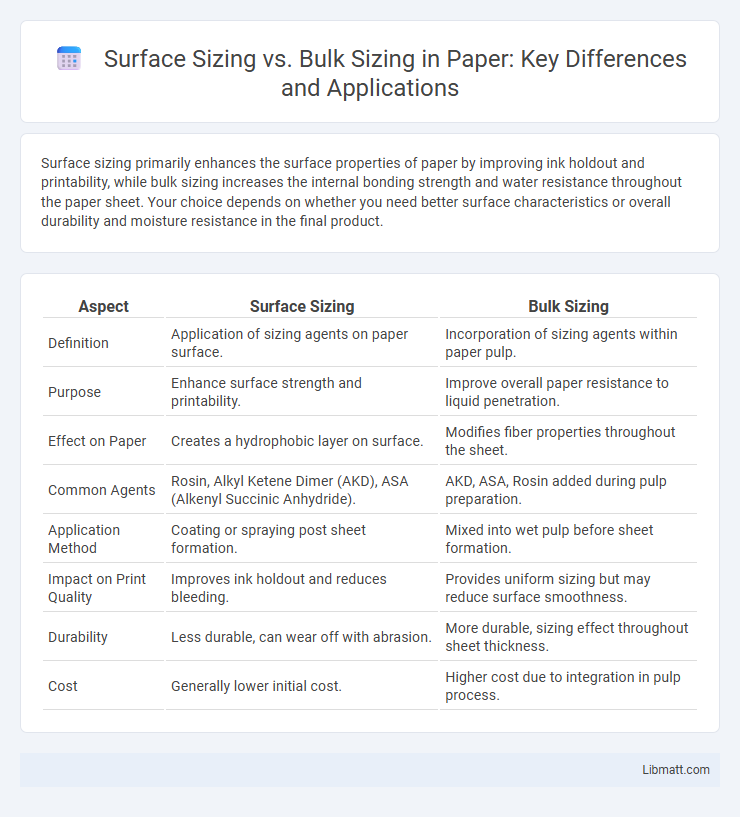

Surface sizing primarily enhances the surface properties of paper by improving ink holdout and printability, while bulk sizing increases the internal bonding strength and water resistance throughout the paper sheet. Your choice depends on whether you need better surface characteristics or overall durability and moisture resistance in the final product.

Table of Comparison

| Aspect | Surface Sizing | Bulk Sizing |

|---|---|---|

| Definition | Application of sizing agents on paper surface. | Incorporation of sizing agents within paper pulp. |

| Purpose | Enhance surface strength and printability. | Improve overall paper resistance to liquid penetration. |

| Effect on Paper | Creates a hydrophobic layer on surface. | Modifies fiber properties throughout the sheet. |

| Common Agents | Rosin, Alkyl Ketene Dimer (AKD), ASA (Alkenyl Succinic Anhydride). | AKD, ASA, Rosin added during pulp preparation. |

| Application Method | Coating or spraying post sheet formation. | Mixed into wet pulp before sheet formation. |

| Impact on Print Quality | Improves ink holdout and reduces bleeding. | Provides uniform sizing but may reduce surface smoothness. |

| Durability | Less durable, can wear off with abrasion. | More durable, sizing effect throughout sheet thickness. |

| Cost | Generally lower initial cost. | Higher cost due to integration in pulp process. |

Introduction to Paper Sizing: Surface vs Bulk

Surface sizing enhances paper's strength and printability by applying a thin adhesive layer to the exterior, improving ink absorption and reducing dusting. Bulk sizing, integrated during the pulp stage, increases internal fiber bonding, resulting in improved water resistance and stiffness throughout the entire sheet. Your choice between surface or bulk sizing affects paper durability, print quality, and suitability for specific applications such as packaging or high-quality printing.

Definition and Purpose of Surface Sizing

Surface sizing refers to the application of a thin layer of sizing agent on the exterior of paper to enhance its surface strength, printability, and resistance to ink absorption, improving overall finish quality. Unlike bulk sizing, which is added during the pulp mixing process to alter the paper's internal properties such as stiffness and water resistance, surface sizing specifically targets surface characteristics without significantly affecting the paper's thickness or flexibility. The purpose of surface sizing is to create a smoother, more uniform surface that optimizes ink holdout, reduces feathering, and enhances the sharpness of printed images and text.

Definition and Purpose of Bulk (Internal) Sizing

Bulk sizing, also known as internal sizing, refers to the process of adding sizing agents directly into the pulp before sheet formation to improve the paper's resistance to water and other liquids. Its primary purpose is to enhance the paper's overall strength, printability, and durability by modifying the fiber properties throughout the sheet. You benefit from bulk sizing when needing consistent liquid repellency and structural integrity throughout the entire paper thickness.

Key Differences Between Surface and Bulk Sizing

Surface sizing involves applying a thin layer of sizing agents on the paper's exterior to improve printability, surface strength, and resistance to ink penetration, while bulk sizing incorporates sizing agents within the paper fibers to enhance overall water resistance and dimensional stability. Surface-sized papers tend to have smoother surfaces and better ink holdout, making them ideal for high-quality printing applications, whereas bulk-sized papers demonstrate improved stiffness and durability suitable for packaging and industrial uses. The choice between surface and bulk sizing depends on the desired balance of surface characteristics and internal fiber properties to meet specific end-use requirements.

Materials and Chemicals Used in Surface and Bulk Sizing

Surface sizing typically involves the application of starches, synthetic polymers like polyvinyl acetate, and natural gums onto the paper surface to enhance strength and printability, while bulk sizing incorporates internal additives such as alkyl ketene dimer (AKD) and alkenyl succinic anhydride (ASA) during the papermaking process to improve water resistance and stiffness throughout the sheet. Materials used in bulk sizing must be well-dispersed to ensure uniform penetration, whereas surface sizing chemicals are applied in controlled amounts to avoid altering the paper's thickness significantly. Your choice between surface and bulk sizing chemicals depends on the desired paper properties, such as surface smoothness versus internal strength and moisture resistance.

Application Methods: Surface vs Bulk Sizing Processes

Surface sizing is applied after the sheet is formed, typically by coating or spraying the sizing agent directly onto the paper surface, enhancing surface strength, smoothness, and printability. Bulk sizing involves adding sizing chemicals directly into the pulp slurry before sheet formation, which improves internal bonding and overall paper strength throughout the sheet. Your choice between surface and bulk sizing depends on the desired paper properties and production process efficiency.

Impacts on Paper Properties: Strength, Printability, and Absorbency

Surface sizing enhances your paper's printability and strength by creating a thin, protective layer that reduces ink absorbency, resulting in sharper images and less feathering. Bulk sizing, added during pulp processing, increases internal fiber bonding, improving overall paper strength and stiffness while maintaining higher absorbency for tasks like writing or watercolor. Balancing surface and bulk sizing optimizes paper properties for specific uses, ensuring durability and desired print quality.

Typical Industry Applications for Each Sizing Type

Surface sizing is primarily used in the production of printing paper, fine art paper, and packaging where enhanced surface strength and printability are essential. Bulk sizing is common in manufacturing paperboard, cardboard, and corrugated materials, where improved internal fiber bonding and stiffness are prioritized. Both sizing methods are critical in papermaking, ensuring the final product meets specific performance criteria for its intended industrial application.

Environmental Considerations of Sizing Approaches

Surface sizing uses less material and energy compared to bulk sizing, leading to a lower environmental footprint in paper production. Bulk sizing involves incorporating chemicals directly into the pulp, which can increase wastewater treatment demands and impact biodegradability. You can reduce your environmental impact by selecting surface sizing methods that optimize paper performance with minimal ecological disruption.

Choosing the Right Sizing Method for Your Paper Products

Surface sizing enhances the external properties of paper, such as printability and water resistance, by applying a thin coating on the surface, making it ideal for high-quality printing and packaging applications. Bulk sizing integrates additives into the paper pulp, improving internal strength, stiffness, and opacity, which benefits products requiring durability and rigidity like cardboard and specialty papers. Your choice between surface and bulk sizing depends on the specific performance requirements, balancing print quality with mechanical strength for optimal paper product functionality.

surface sizing vs bulk sizing Infographic

libmatt.com

libmatt.com