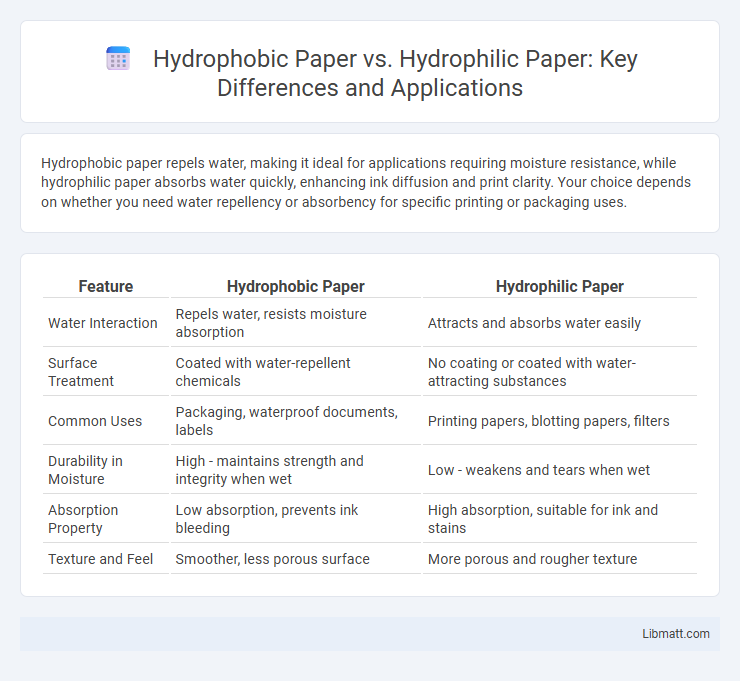

Hydrophobic paper repels water, making it ideal for applications requiring moisture resistance, while hydrophilic paper absorbs water quickly, enhancing ink diffusion and print clarity. Your choice depends on whether you need water repellency or absorbency for specific printing or packaging uses.

Table of Comparison

| Feature | Hydrophobic Paper | Hydrophilic Paper |

|---|---|---|

| Water Interaction | Repels water, resists moisture absorption | Attracts and absorbs water easily |

| Surface Treatment | Coated with water-repellent chemicals | No coating or coated with water-attracting substances |

| Common Uses | Packaging, waterproof documents, labels | Printing papers, blotting papers, filters |

| Durability in Moisture | High - maintains strength and integrity when wet | Low - weakens and tears when wet |

| Absorption Property | Low absorption, prevents ink bleeding | High absorption, suitable for ink and stains |

| Texture and Feel | Smoother, less porous surface | More porous and rougher texture |

Introduction to Hydrophobic and Hydrophilic Papers

Hydrophobic paper repels water due to its surface properties, making it ideal for moisture-resistant packaging and outdoor applications, while hydrophilic paper absorbs water, enhancing ink adhesion and absorption in printing and medical uses. Hydrophobic papers often utilize coatings like fluoropolymers or silica nanoparticles, whereas hydrophilic papers employ cellulose fibers with high affinity to water molecules. Understanding the contrast in water interaction between hydrophobic and hydrophilic papers is essential for selecting appropriate materials in industries such as packaging, printing, and biomedical fields.

Defining Hydrophobic and Hydrophilic Properties

Hydrophobic paper possesses surface properties that repel water, causing droplets to bead up and resist absorption, due to low surface energy materials or coatings like fluoropolymers. Hydrophilic paper, in contrast, readily absorbs water through its porous cellulose fibers, promoting wetting and fluid penetration because of its high surface energy and affinity for polar molecules. Understanding these intrinsic surface interactions is essential for applications in filtration, packaging, and biosensors where moisture management is critical.

Manufacturing Processes: How Each Paper is Made

Hydrophobic paper is manufactured by integrating water-repellent agents such as wax, silicone, or fluorochemicals into the cellulose fibers during the papermaking process, often through surface coating or impregnation techniques. Hydrophilic paper is produced by maintaining or enhancing the natural affinity of cellulose fibers for water, typically using untreated pulp or additives like starch and sizing agents to promote water absorption. The key distinction lies in hydrophobic paper's chemical modifications that prevent water penetration, whereas hydrophilic paper's formulation supports moisture retention and absorption.

Surface Chemistry: Understanding Water Interactions

Hydrophobic paper features a surface chemistry that repels water, preventing absorption by creating a barrier with low surface energy, often treated with fluorinated or silicone-based compounds. In contrast, hydrophilic paper naturally attracts and absorbs water due to its high surface energy and polar functional groups like hydroxyls, promoting wetting and fluid dispersion. Understanding these water interactions is crucial for selecting the right paper type for applications involving moisture control, ink absorption, or fluid resistance to optimize Your project's performance.

Key Applications of Hydrophobic Paper

Hydrophobic paper is widely used in packaging industries to provide moisture resistance and enhance product durability, especially for food packaging and electronics protection. Its water-repellent properties make it ideal for outdoor applications, such as maps, labels, and signage that require durability under wet conditions. Your choice of hydrophobic paper can improve product longevity by preventing moisture absorption and reducing the risk of damage in humid environments.

Key Applications of Hydrophilic Paper

Hydrophilic paper excels in key applications such as medical diagnostics, where its water-attracting properties enhance fluid absorption for rapid test results. It is widely used in chromatography and water filtration, leveraging its ability to interact with aqueous solutions for efficient separation and purification processes. Environmental sensors also benefit from hydrophilic paper by enabling accurate detection of moisture and pollutants through improved fluid retention and interaction.

Performance Comparison: Absorption and Repellency

Hydrophobic paper exhibits superior repellency by resisting water absorption, making it ideal for applications requiring moisture protection and durability. In contrast, hydrophilic paper demonstrates high absorption rates, allowing efficient fluid uptake valuable in filtration, medical, and printing uses. The performance comparison highlights hydrophobic paper's ability to maintain structural integrity in wet conditions, whereas hydrophilic paper excels in liquid retention and interaction.

Environmental Impact and Sustainability Concerns

Hydrophobic paper utilizes water-repellent coatings, often based on synthetic chemicals, which can challenge biodegradability and complicate recycling processes, raising environmental concerns. Hydrophilic paper, typically untreated or minimally processed, offers better compostability and easier integration into recycling streams, enhancing sustainability. Choosing hydrophilic paper supports reduced chemical use and lowers ecological footprints compared to hydrophobic counterparts.

Selecting the Right Paper for Specific Industries

Hydrophobic paper resists water and moisture, making it ideal for packaging in food, pharmaceuticals, and electronics industries where protection from liquids is crucial. Hydrophilic paper absorbs moisture quickly, enhancing applications in medical diagnostics, hygiene products, and filtration where fluid interaction is necessary. Selecting the right paper depends on industry requirements for moisture resistance or absorption to ensure product functionality and durability.

Future Trends in Advanced Paper Technologies

Future trends in advanced paper technologies emphasize the development of hydrophobic paper with enhanced water resistance for packaging and electronics, driven by innovations in nanocoatings and biodegradable materials. Hydrophilic paper advancements focus on improving absorption rates and biocompatibility for medical and filtration applications through functionalized cellulose fibers and superabsorbent polymers. Emerging research combines both properties in hybrid papers for smart packaging and environmental sensing, leveraging tunable surface chemistry and sustainable production methods.

Hydrophobic paper vs hydrophilic paper Infographic

libmatt.com

libmatt.com