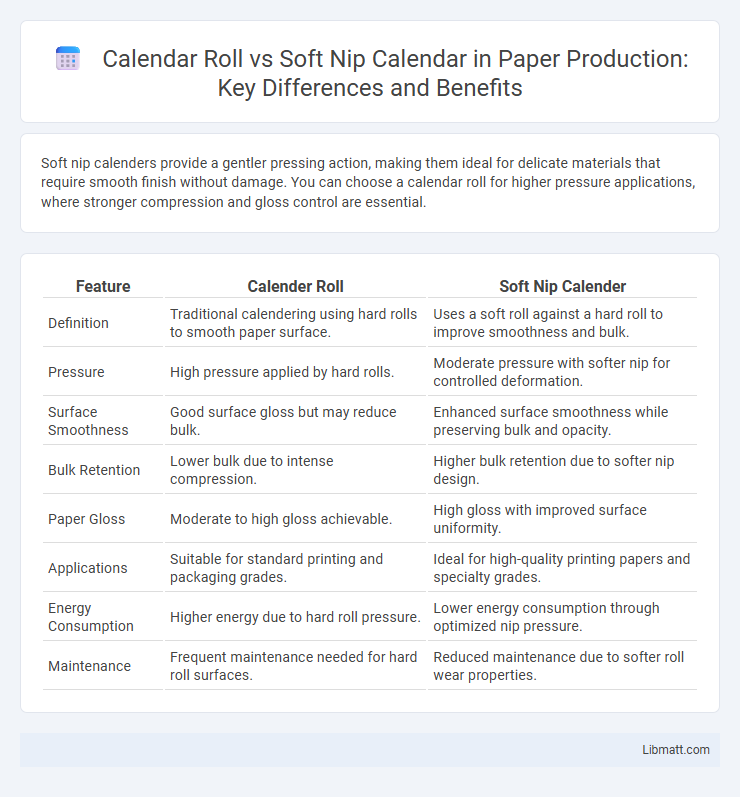

Soft nip calenders provide a gentler pressing action, making them ideal for delicate materials that require smooth finish without damage. You can choose a calendar roll for higher pressure applications, where stronger compression and gloss control are essential.

Table of Comparison

| Feature | Calender Roll | Soft Nip Calender |

|---|---|---|

| Definition | Traditional calendering using hard rolls to smooth paper surface. | Uses a soft roll against a hard roll to improve smoothness and bulk. |

| Pressure | High pressure applied by hard rolls. | Moderate pressure with softer nip for controlled deformation. |

| Surface Smoothness | Good surface gloss but may reduce bulk. | Enhanced surface smoothness while preserving bulk and opacity. |

| Bulk Retention | Lower bulk due to intense compression. | Higher bulk retention due to softer nip design. |

| Paper Gloss | Moderate to high gloss achievable. | High gloss with improved surface uniformity. |

| Applications | Suitable for standard printing and packaging grades. | Ideal for high-quality printing papers and specialty grades. |

| Energy Consumption | Higher energy due to hard roll pressure. | Lower energy consumption through optimized nip pressure. |

| Maintenance | Frequent maintenance needed for hard roll surfaces. | Reduced maintenance due to softer roll wear properties. |

Introduction to Calender Roll and Soft Nip Calender

Calender rolls are essential components in paper manufacturing, providing smoothness and gloss by passing the paper web between hard, heated rolls under high pressure. Soft nip calenders differ by incorporating a flexible, compliant roll paired with a hard roll, enabling more uniform pressure distribution and improved surface finishing without damaging the paper structure. Your selection between these calender types impacts paper quality, gloss, and bulk, with soft nip calenders offering enhanced control for delicate or specialty papers.

Defining Calender Roll Technology

Calender roll technology involves applying controlled pressure and heat using a series of rollers to smooth or finish materials like paper and textiles. Soft nip calenders use a combination of hard and soft rolls to enhance surface properties by providing gentle, uniform pressure, which reduces defects and improves gloss and smoothness. Understanding these technologies helps optimize your finishing processes for improved product quality and efficiency.

Understanding Soft Nip Calendering

Soft nip calendering uses a softer roller material combined with a harder backup roller to enhance paper smoothness and gloss while reducing sheet marking. This process improves surface finish without excessive pressure, preserving your product's structural integrity and strength. Compared to calendar rolls, soft nip calenders offer better control over thickness and surface quality, optimizing paper properties for high-performance applications.

Key Differences Between Calender Roll and Soft Nip Calender

Calender roll and soft nip calender differ mainly in their roll composition and nip pressure, which significantly affect paper surface quality and texture. Calender rolls are typically hard and provide higher pressure, resulting in smoother, glossier surfaces, while soft nip calenders use a combination of a hard roll and a compliant roll to create a gentler nip that enhances bulk and reduces surface damage. Your choice depends on the desired balance between gloss, smoothness, and paper bulk for specific end-use applications.

Advantages of Calender Roll Systems

Calender roll systems offer superior uniform pressure distribution, enhancing surface smoothness and gloss in paper production. These systems provide higher mechanical stability and precise control over thickness, leading to consistent product quality. You benefit from increased operational efficiency and reduced maintenance compared to soft nip calenders, making them ideal for large-scale industrial use.

Benefits of Soft Nip Calender Processes

Soft nip calender processes enhance surface smoothness and gloss by applying controlled pressure through a flexible roll, reducing sheet defects and improving printability. You benefit from increased bulk retention and better moisture uniformity compared to traditional calendar rolls, which often compress the material more aggressively. The soft nip method also extends equipment life and lowers energy consumption by minimizing mechanical stress and heat buildup during production.

Applications in the Paper and Textile Industries

Calendar roll systems are widely used in the paper industry to enhance surface smoothness and gloss by applying controlled pressure and heat, ideal for producing high-quality printing paper and coated paper grades. Soft nip calendar technology, featuring a resilient material roll combined with a hard roll, offers superior control over calendering pressure, making it well-suited for delicate textile fabrics and specialty papers requiring uniform thickness and improved surface properties. Both technologies optimize product characteristics, but soft nip calendars excel in handling sensitive materials without damaging fibers, enhancing applications in textiles and premium paper production.

Impact on Product Quality and Surface Properties

Soft nip calenders apply controlled pressure and temperature, resulting in enhanced surface smoothness and gloss, which improves the product's visual appeal and printability. Calendar rolls, with harder surfaces, provide higher calendering pressure for better thickness control but can cause surface imperfections or reduced gloss. Your choice between soft nip calender and calendar roll directly affects product quality by balancing smoothness, gloss, and dimensional stability.

Energy Efficiency and Operational Considerations

Calender roll systems typically consume more energy due to higher pressure requirements and friction between rolls, whereas soft nip calenders use elastic covers to achieve similar or better surface finish with reduced energy input. Soft nip calenders offer operational advantages by minimizing wear on both rolls and paper, leading to lower maintenance costs and less downtime. Your choice between these two should consider overall energy savings and smoother operational cycles that soft nip technology provides.

Future Trends in Calendering Technologies

Future trends in calendering technologies emphasize enhanced precision and energy efficiency, with innovations focusing on advanced roll materials and smart temperature control systems to improve product quality and reduce waste. Soft nip calenders are gaining traction for their ability to apply uniform pressure without damaging sensitive materials, offering better surface finishing and flexibility for diverse applications. You can expect ongoing integration of AI-driven monitoring and adaptive controls to optimize calender roll performance and extend equipment lifespan.

calender roll vs soft nip calender Infographic

libmatt.com

libmatt.com