Multiwall sack paper offers superior strength and durability compared to single wall sack paper, making it ideal for heavy-duty packaging and protection of bulk materials. Your choice depends on the weight and type of contents, with single wall suitable for lighter loads and multiwall providing enhanced resistance to tearing and moisture.

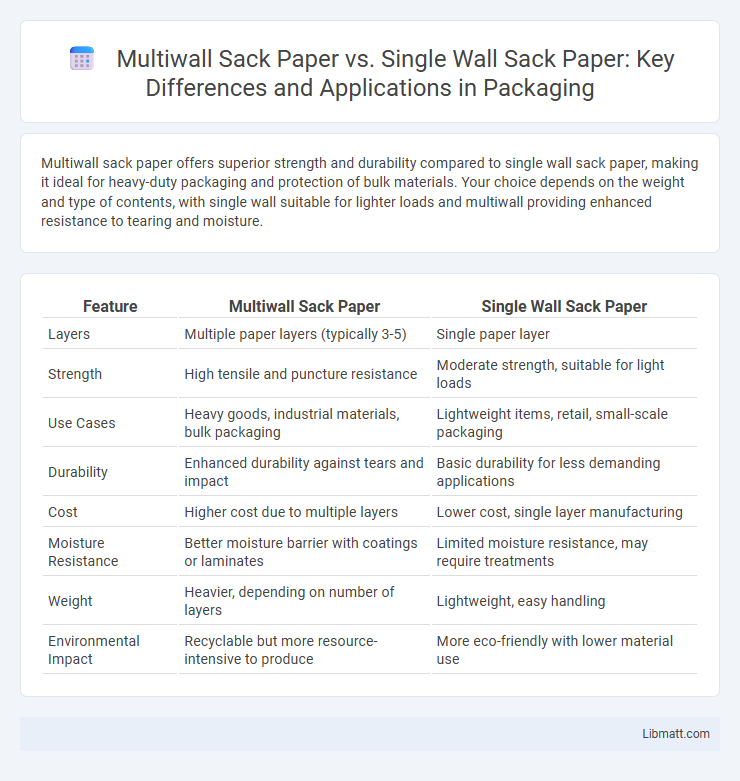

Table of Comparison

| Feature | Multiwall Sack Paper | Single Wall Sack Paper |

|---|---|---|

| Layers | Multiple paper layers (typically 3-5) | Single paper layer |

| Strength | High tensile and puncture resistance | Moderate strength, suitable for light loads |

| Use Cases | Heavy goods, industrial materials, bulk packaging | Lightweight items, retail, small-scale packaging |

| Durability | Enhanced durability against tears and impact | Basic durability for less demanding applications |

| Cost | Higher cost due to multiple layers | Lower cost, single layer manufacturing |

| Moisture Resistance | Better moisture barrier with coatings or laminates | Limited moisture resistance, may require treatments |

| Weight | Heavier, depending on number of layers | Lightweight, easy handling |

| Environmental Impact | Recyclable but more resource-intensive to produce | More eco-friendly with lower material use |

Introduction to Sack Paper Types

Single wall sack paper consists of a single layer of kraft or linerboard, offering basic strength and durability for packaging lightweight to medium-weight goods. Multiwall sack paper features multiple layers bonded together, enhancing tear resistance, puncture strength, and moisture protection, making it ideal for heavy-duty or industrial packaging. The choice between single wall and multiwall sack paper depends on the product's weight, handling requirements, and environmental exposure during transportation and storage.

What is Multiwall Sack Paper?

Multiwall sack paper consists of several layers of kraft paper combined to create enhanced strength and durability, commonly used for packaging heavy or bulky materials like cement, flour, and animal feed. This multi-layer structure provides superior tear resistance, moisture protection, and puncture strength compared to single wall sack paper, which has only one layer and is suitable for lighter loads. The layered design of multiwall sacks ensures better performance in handling, shipping, and storage conditions, making them ideal for industrial and agricultural applications.

What is Single Wall Sack Paper?

Single wall sack paper consists of a single layer of kraft paper typically used for packaging lightweight goods such as flour, sugar, or cement. Its strength and durability come from the high-quality fibers and specialized pulping process, making it resistant to tearing and moisture. This type of paper is ideal for applications requiring moderate protection and flexibility.

Key Material Differences

Multiwall sack paper consists of multiple layers of kraft paper or liners, providing enhanced strength, durability, and puncture resistance compared to single wall sack paper, which uses only a single layer. Multiwall paper is suitable for heavy or bulk materials requiring extra protection, while single wall paper is often used for lighter loads with less demanding storage conditions. Your choice depends on the weight and fragility of the contents, as well as the transportation needs.

Strength and Durability Comparison

Multiwall sack paper offers superior strength and durability compared to single wall sack paper due to its layered construction, which enhances tear resistance and load-bearing capacity. The multiple layers in multiwall sacks provide better protection against moisture, punctures, and abrasion, making them ideal for transporting heavy or abrasive materials. In contrast, single wall sack paper, with only one layer, is less robust and more prone to damage under heavy loads or harsh handling conditions.

Weight and Handling Considerations

Multiwall sack paper offers enhanced durability and weight distribution due to its multiple layers, making it ideal for heavy or bulkier materials, while single wall sack paper is lighter and easier to handle but less resistant to punctures and tears. The increased weight of multiwall sacks requires more robust handling equipment and storage solutions, whereas single wall sacks provide greater flexibility for manual handling and transportation. Choosing between the two depends on balancing the need for protection against the ease of handling and overall weight efficiency.

Common Applications of Multiwall Sack Paper

Multiwall sack paper is commonly used for packaging heavy or bulk materials such as cement, flour, animal feed, and chemicals due to its superior strength and durability compared to single wall sack paper. Its multiple layers provide enhanced tear resistance and moisture protection, making it ideal for industrial and agricultural applications. Your choice of multiwall sack paper ensures reliable performance in transporting and storing products that demand robust packaging solutions.

Typical Uses for Single Wall Sack Paper

Single wall sack paper is commonly used for packaging lightweight materials such as flour, cement, and animal feed due to its adequate strength and cost-efficiency. It is suitable for single-layer bags that require moderate durability and protection during handling and transportation. This type of paper is ideal for packaging applications where moisture resistance and puncture protection are less critical.

Environmental Impact and Sustainability

Multiwall sack paper offers enhanced environmental benefits by using multiple layers of recyclable kraft paper, increasing durability while reducing the need for plastic liners commonly used in single wall sacks. Single wall sack paper, though lighter, often requires coatings or additives that can hinder recyclability and contribute to landfill waste. Choosing multiwall sacks can support your sustainability goals by maximizing material efficiency and promoting a circular economy in packaging.

Choosing the Right Sack Paper for Your Needs

Multiwall sack paper offers superior strength, moisture resistance, and durability compared to single wall sack paper, making it ideal for heavy or bulky products such as cement, chemicals, and grains. Single wall sack paper is lightweight and cost-effective, best suited for lighter, less demanding applications like packaging food or small hardware. Assess your product's weight, handling conditions, and environmental exposure to determine whether multiwall or single wall sack paper aligns with your packaging requirements.

Multiwall sack paper vs single wall sack paper Infographic

libmatt.com

libmatt.com