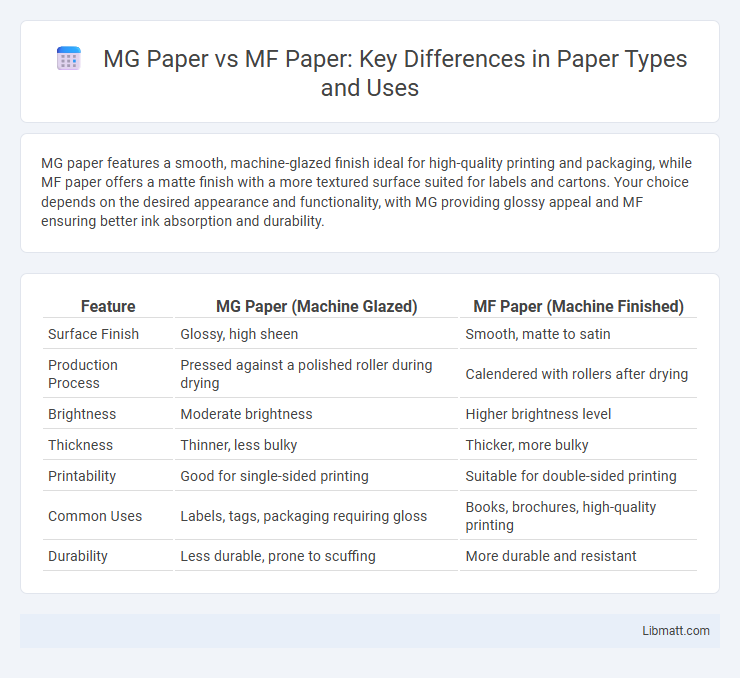

MG paper features a smooth, machine-glazed finish ideal for high-quality printing and packaging, while MF paper offers a matte finish with a more textured surface suited for labels and cartons. Your choice depends on the desired appearance and functionality, with MG providing glossy appeal and MF ensuring better ink absorption and durability.

Table of Comparison

| Feature | MG Paper (Machine Glazed) | MF Paper (Machine Finished) |

|---|---|---|

| Surface Finish | Glossy, high sheen | Smooth, matte to satin |

| Production Process | Pressed against a polished roller during drying | Calendered with rollers after drying |

| Brightness | Moderate brightness | Higher brightness level |

| Thickness | Thinner, less bulky | Thicker, more bulky |

| Printability | Good for single-sided printing | Suitable for double-sided printing |

| Common Uses | Labels, tags, packaging requiring gloss | Books, brochures, high-quality printing |

| Durability | Less durable, prone to scuffing | More durable and resistant |

Understanding MG Paper and MF Paper

MG paper, or Machine Glazed paper, features one shiny, smooth side achieved through a high-speed calendar roll in papermaking, making it ideal for packaging and labels requiring a glossy finish. MF paper, or Machine Finished paper, has a uniform matte texture on both sides, produced by a mechanical finishing process, suitable for printing materials that demand better ink absorption and a non-reflective surface. The choice between MG and MF papers depends on the desired aesthetic and functional properties, with MG paper emphasizing gloss and MF paper prioritizing print quality and texture.

Key Differences Between MG and MF Paper

MG (Machine Glazed) paper features a glossy, smooth finish on one side achieved through a calendaring process, while MF (Machine Finished) paper offers a matte, non-coated surface with uniform texture on both sides. MG paper is commonly used for labels and packaging requiring high gloss and printability, whereas MF paper suits applications needing good bulk and stiffness, such as book pages and offset printing. The key differences lie in surface finish, gloss level, and suitability for printing processes, with MG providing higher gloss and moisture resistance compared to the smoother, less reflective MF paper.

Manufacturing Process of MG Paper

Machine Glazed (MG) paper is produced through a manufacturing process that involves pressing the paper pulp against a highly polished steel cylinder, resulting in one smooth, glossy side and one rough side. This manufacturing technique enhances the paper's strength and stiffness by compacting the fibers on the glazed side, making it ideal for applications such as packaging and labels. Compared to Machine Finished (MF) paper, which undergoes additional calendering for both sides, MG paper offers a cost-effective solution with distinct texture and durability attributes.

How MF Paper is Produced

MF paper is produced through a meticulous mechanical pulping process that involves grinding wood chips with water to separate fibers without chemical treatment, preserving most of the wood's lignin. This results in a paper with higher opacity, bulk, and stiffness compared to MG paper, which is coated and made using chemical pulp. Your choice of MF paper supports printing needs requiring durability and opacity without the smooth, glossy finish typical of MG paper.

Physical Properties: MG vs. MF Paper

Machine Glazed (MG) paper features a smooth, glossy surface on one side, created by pressing the paper pulp against a highly polished cylinder, resulting in excellent brightness and stiffness ideal for packaging applications. Machine Finished (MF) paper offers a more uniform finish on both sides, providing moderate smoothness and strength, commonly used for printing and general-purpose tasks. MG paper generally exhibits higher caliper and surface gloss, while MF paper delivers better printability and flexibility due to its balanced surface texture.

Common Applications of MG Paper

MG paper, or machine-glazed paper, is widely used for packaging applications like grocery bags, food wrapping, and paper sacks due to its smooth, glossy surface on one side and rough texture on the other. Its moisture resistance and durability make it ideal for products requiring protection from dust and humidity. Your choice of MG paper ensures a balance between cost-efficiency and functional performance in packaging solutions.

Typical Uses of MF Paper

MF paper, short for machine-finished paper, is commonly used in printing books, magazines, and catalogs due to its smooth surface and durability. Its suitability for high-speed printing processes makes MF paper ideal for mass production of documents requiring sharp text and consistent image quality. You'll typically find MF paper in educational materials, commercial printing, and everyday office use.

Cost Comparison: MG Paper vs. MF Paper

Machine Glazed (MG) paper generally costs less than Machine Finished (MF) paper due to its simpler production process and lower finishing requirements. MG paper is produced by drying the paper on a highly polished cylinder, which imparts a glossy finish on one side while keeping the reverse rough, reducing manufacturing expenses. In contrast, MF paper undergoes a calendaring process on both sides to achieve a smooth finish, increasing production costs and resulting in a higher market price.

Environmental Impact and Sustainability

MG paper (Machine Glazed) is typically coated with a shiny surface that can make it less biodegradable compared to MF paper (Machine Finished), which undergoes minimal coatings and maintains higher recyclability. The manufacturing process of MG paper often involves more energy and chemical usage, leading to a larger carbon footprint relative to MF paper, which is considered more environmentally friendly due to its simpler production. MF paper's better compostability and lower resource consumption contribute significantly to sustainability efforts by reducing waste and promoting eco-friendly packaging solutions.

Choosing the Right Paper: MG or MF?

Choosing the right paper between MG (machine glazed) and MF (machine finished) depends on your printing requirements and desired finish. MG paper features a smooth, shiny surface ideal for labels and packaging needing high gloss and sharp print quality, while MF paper offers a duller, matte finish suitable for applications requiring better ink adhesion and easier writing. Your selection should consider the aesthetic impact, printing method, and post-printing processes to ensure the best performance for your project.

MG paper vs MF paper Infographic

libmatt.com

libmatt.com