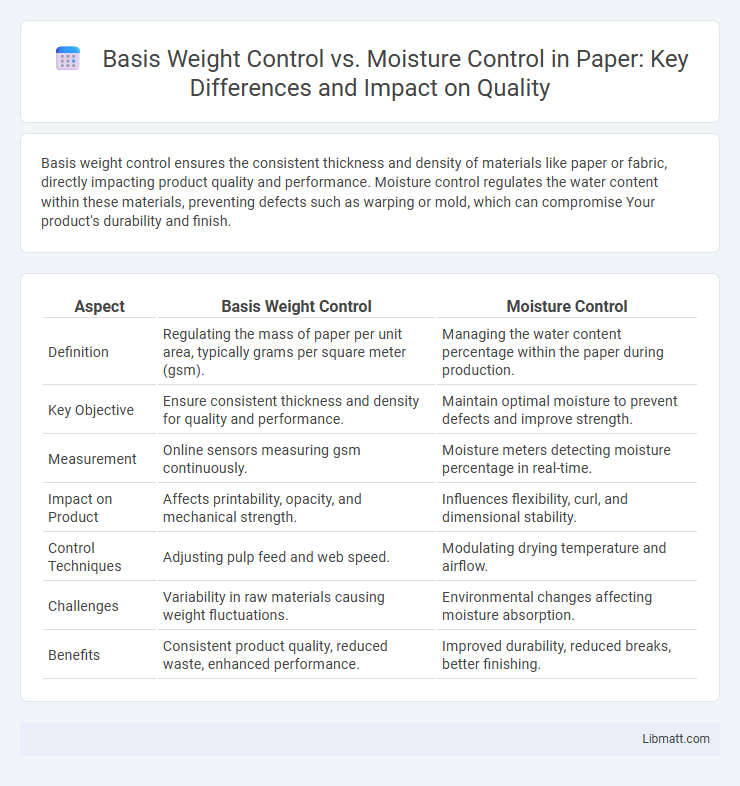

Basis weight control ensures the consistent thickness and density of materials like paper or fabric, directly impacting product quality and performance. Moisture control regulates the water content within these materials, preventing defects such as warping or mold, which can compromise Your product's durability and finish.

Table of Comparison

| Aspect | Basis Weight Control | Moisture Control |

|---|---|---|

| Definition | Regulating the mass of paper per unit area, typically grams per square meter (gsm). | Managing the water content percentage within the paper during production. |

| Key Objective | Ensure consistent thickness and density for quality and performance. | Maintain optimal moisture to prevent defects and improve strength. |

| Measurement | Online sensors measuring gsm continuously. | Moisture meters detecting moisture percentage in real-time. |

| Impact on Product | Affects printability, opacity, and mechanical strength. | Influences flexibility, curl, and dimensional stability. |

| Control Techniques | Adjusting pulp feed and web speed. | Modulating drying temperature and airflow. |

| Challenges | Variability in raw materials causing weight fluctuations. | Environmental changes affecting moisture absorption. |

| Benefits | Consistent product quality, reduced waste, enhanced performance. | Improved durability, reduced breaks, better finishing. |

Understanding Basis Weight Control

Basis weight control ensures consistent paper or fabric thickness by precisely measuring mass per unit area, which directly impacts product quality and manufacturing efficiency. Accurate basis weight measurement optimizes resource usage and reduces material waste, essential for process stability in industries such as paper production and textiles. Moisture control complements this by managing water content, but basis weight control remains central to maintaining dimensional accuracy and product specifications.

Defining Moisture Control in Paper Manufacturing

Moisture control in paper manufacturing refers to the precise regulation of water content within the paper web to ensure product quality, stability, and consistency during production. Effective moisture control prevents issues such as warping, dimensional instability, and poor printability by maintaining optimal moisture levels throughout drying and calendaring processes. Unlike basis weight control, which focuses on the mass of paper per unit area, moisture control directly impacts the mechanical properties and final performance characteristics of the paper.

Importance of Basis Weight in Product Quality

Basis weight control directly impacts product quality by ensuring consistent material density, which affects strength, thickness, and durability. Precise control of basis weight minimizes variability in the final product, enhancing uniformity and customer satisfaction. Moisture control complements this by stabilizing the physical properties, but maintaining accurate basis weight is critical for achieving reliable and predictable quality standards.

Role of Moisture Content in Paper Performance

Moisture content plays a critical role in paper performance by influencing dimensional stability, printability, and strength properties. Maintaining precise moisture levels ensures consistent basis weight control, which directly affects the paper's weight uniformity and overall quality. Effective moisture control prevents issues like curl, cockling, and ink set-off, enhancing the paper's functionality during printing and converting processes.

Measurement Techniques for Basis Weight

Measurement techniques for basis weight primarily include beta-ray absorption, infrared sensors, and nuclear gauge methods, which provide accurate, real-time data crucial for quality control in paper and textile production. These techniques detect the mass per unit area by measuring the attenuation of radiation or the reflection of light, ensuring consistent product density and strength. Accurate basis weight control enhances Your production efficiency by reducing material waste and maintaining product specifications.

Methods of Monitoring Moisture Levels

Methods of monitoring moisture levels in basis weight control include infrared sensors, capacitance sensors, and microwave moisture meters. These technologies provide real-time, accurate measurements of moisture content in paper or textile production, enabling precise adjustments to maintain product quality. Implementing advanced moisture monitoring systems reduces waste and enhances process efficiency by ensuring consistent material properties.

Challenges in Basis Weight Regulation

In papermaking, challenges in basis weight regulation stem from variations in raw material properties and machine speed fluctuations that affect sheet formation consistency. Precise control demands real-time monitoring systems capable of detecting subtle changes in basis weight to adjust fiber flow accurately. Unlike moisture control, which relies on drying and evaporation processes, basis weight control focuses on fiber mass per unit area, requiring sophisticated feedback loops and advanced sensors for optimal performance.

Impact of Moisture Fluctuations on Production

Moisture fluctuations directly influence basis weight control by causing variations in sheet density and thickness, leading to inconsistent product quality. Your production efficiency can decline as moisture-induced dimensional changes require frequent adjustments to maintain tolerances, increasing downtime. Precise moisture control stabilizes the papermaking process, reducing waste and ensuring more accurate basis weight measurements.

Integrating Basis Weight and Moisture Control Systems

Integrating basis weight and moisture control systems enhances production efficiency by ensuring consistent paper quality and reducing waste. Advanced sensors monitor both basis weight and moisture in real-time, enabling precise adjustments to maintain optimal sheet properties. Your manufacturing process benefits from improved stability, lower energy consumption, and higher product uniformity through synchronized control strategies.

Optimizing Efficiency: Basis Weight vs. Moisture Control

Optimal paper production efficiency depends on precise basis weight control and moisture control, each impacting product quality and process stability differently. Basis weight control ensures consistent sheet density and strength, reducing waste and improving runnability, while moisture control directly influences drying energy consumption and final product moisture equilibrium. Balancing both parameters through integrated sensor technology and real-time feedback systems maximizes operational efficiency and minimizes production costs.

Basis weight control vs moisture control Infographic

libmatt.com

libmatt.com