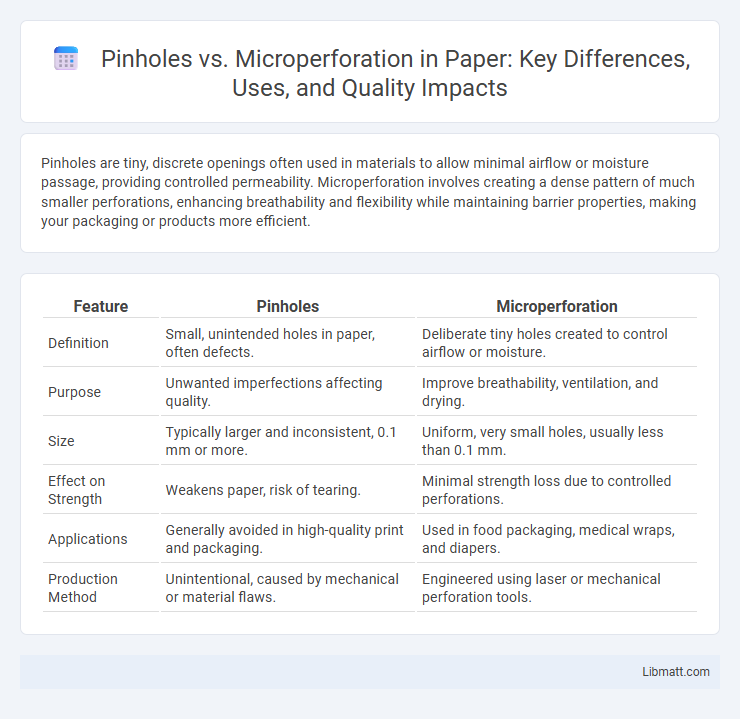

Pinholes are tiny, discrete openings often used in materials to allow minimal airflow or moisture passage, providing controlled permeability. Microperforation involves creating a dense pattern of much smaller perforations, enhancing breathability and flexibility while maintaining barrier properties, making your packaging or products more efficient.

Table of Comparison

| Feature | Pinholes | Microperforation |

|---|---|---|

| Definition | Small, unintended holes in paper, often defects. | Deliberate tiny holes created to control airflow or moisture. |

| Purpose | Unwanted imperfections affecting quality. | Improve breathability, ventilation, and drying. |

| Size | Typically larger and inconsistent, 0.1 mm or more. | Uniform, very small holes, usually less than 0.1 mm. |

| Effect on Strength | Weakens paper, risk of tearing. | Minimal strength loss due to controlled perforations. |

| Applications | Generally avoided in high-quality print and packaging. | Used in food packaging, medical wraps, and diapers. |

| Production Method | Unintentional, caused by mechanical or material flaws. | Engineered using laser or mechanical perforation tools. |

Understanding Pinholes and Microperforation

Pinholes are tiny, microscopic holes that penetrate a material completely, often causing structural weaknesses or unwanted leaks. Microperforation involves creating controlled, uniform tiny holes that allow breathability and moisture passage while maintaining material integrity. Understanding the difference helps you select the right method for applications such as packaging, filtration, or breathable films.

Key Differences Between Pinholes and Microperforation

Pinholes are small, discrete holes typically ranging from 0.1 to 0.5 millimeters in diameter, whereas microperforation consists of numerous tiny perforations measuring less than 0.1 millimeters each, creating a fine mesh-like pattern. Pinholes primarily enhance breathability and moisture control in packaging materials, while microperforation improves air and gas exchange, especially useful in modified atmosphere packaging to extend product shelf life. The production process for pinholes often involves mechanical piercing, whereas microperforation uses laser or precision tools to create uniform, high-density perforations without compromising material integrity.

Manufacturing Processes: Pinholes vs Microperforation

Pinholes are created using laser drilling or mechanical needle penetration, resulting in small, discrete holes that puncture a material for breathability or liquid release. Microperforation involves precision-engineered tools or laser systems that generate numerous tiny holes with consistent size and pattern, enhancing airflow and transparency without compromising strength. The manufacturing process for microperforation generally requires advanced machinery for uniformity, whereas pinhole creation can involve simpler, less precise methods.

Applications in Packaging and Preservation

Pinholes and microperforation play crucial roles in packaging and preservation by controlling gas exchange and moisture levels to extend product shelf life. Pinholes, often microscopic defects, may unintentionally compromise packaging integrity, while microperforation is a deliberate technique that creates tiny, precise holes to enhance breathability and prolong freshness, especially for perishable foods. When optimizing Your packaging design, leveraging microperforation technology ensures balanced ventilation, reduces condensation, and preserves product quality without sacrificing durability.

Impact on Airflow and Moisture Control

Pinholes create larger openings allowing increased airflow but can compromise moisture control by permitting more humidity exchange, whereas microperforation offers finer holes that maintain controlled ventilation while reducing moisture penetration. Your choice depends on balancing airflow needs with moisture barriers, where microperforation provides a more precise regulation for delicate environments. Understanding the differences in permeability helps optimize packaging solutions to protect contents effectively from moisture damage while ensuring adequate breathability.

Advantages of Pinholes in Various Industries

Pinholes offer precise airflow control in packaging, enhancing product freshness and shelf life by allowing gradual gas exchange, crucial in the food industry. Their cost-effective manufacturing and easy integration into materials make them ideal for medical applications, where maintaining sterile environments is vital. Compared to microperforation, pinholes provide greater durability and consistent performance in industrial processes like electronics cooling, ensuring reliable ventilation without compromising structural integrity.

Benefits of Microperforation Techniques

Microperforation techniques improve ventilation and moisture control in packaging, extending the shelf life of fresh produce by preventing condensation and maintaining optimal humidity levels. Unlike pinholes, microperforations offer precise hole size and distribution, ensuring better gas exchange without compromising package integrity. Your products benefit from enhanced freshness and reduced spoilage, leading to increased customer satisfaction and reduced waste.

Choosing the Right Method for Your Needs

Pinholes offer precise, small perforations ideal for packaging that requires breathability without compromising strength, while microperforation provides a finer, more uniform pattern suited for delicate products needing controlled ventilation. Selecting the right method depends on your specific application, material type, and desired airflow rate. Assessing these factors ensures optimal product protection and functionality tailored to your needs.

Quality Control and Detection Methods

Pinholes and microperforations in packaging films are critical defects affecting barrier properties and product shelf life, requiring precise quality control. Detection methods for pinholes include high-voltage leak testers and bubble emission tests, while microperforations often necessitate advanced techniques such as laser scanning microscopy or coated film inspection systems. Ensuring accurate identification of these defects improves packaging integrity and maintains compliance with industry standards.

Future Trends and Innovations in Perforation Technology

Future trends in perforation technology emphasize advanced microperforation techniques that enhance material breathability and strength while reducing waste compared to traditional pinholes. Innovations include laser-based microperforation allowing precise customization for packaging and filtration industries, improving product freshness and environmental sustainability. Your business can benefit from these cutting-edge solutions by adopting more efficient, eco-friendly perforation methods that meet evolving market demands.

Pinholes vs microperforation Infographic

libmatt.com

libmatt.com