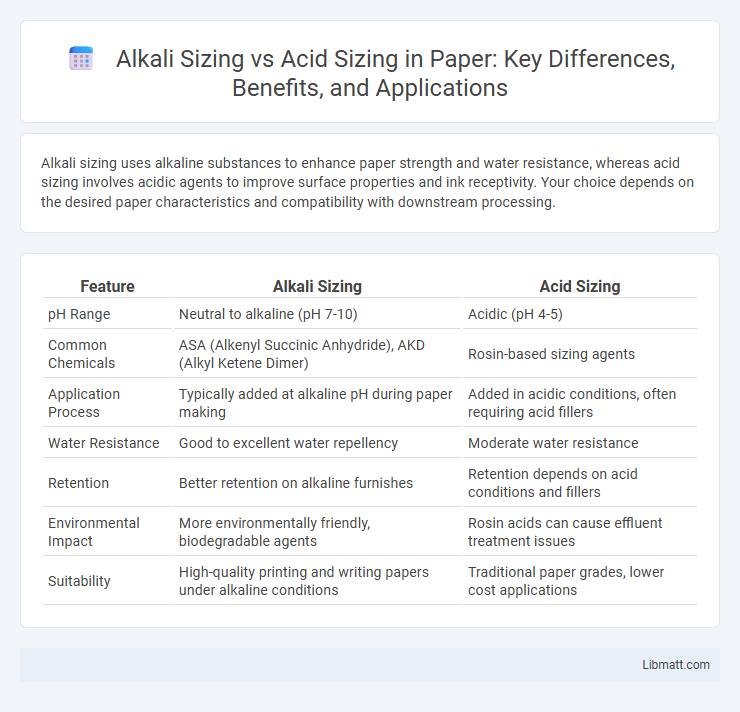

Alkali sizing uses alkaline substances to enhance paper strength and water resistance, whereas acid sizing involves acidic agents to improve surface properties and ink receptivity. Your choice depends on the desired paper characteristics and compatibility with downstream processing.

Table of Comparison

| Feature | Alkali Sizing | Acid Sizing |

|---|---|---|

| pH Range | Neutral to alkaline (pH 7-10) | Acidic (pH 4-5) |

| Common Chemicals | ASA (Alkenyl Succinic Anhydride), AKD (Alkyl Ketene Dimer) | Rosin-based sizing agents |

| Application Process | Typically added at alkaline pH during paper making | Added in acidic conditions, often requiring acid fillers |

| Water Resistance | Good to excellent water repellency | Moderate water resistance |

| Retention | Better retention on alkaline furnishes | Retention depends on acid conditions and fillers |

| Environmental Impact | More environmentally friendly, biodegradable agents | Rosin acids can cause effluent treatment issues |

| Suitability | High-quality printing and writing papers under alkaline conditions | Traditional paper grades, lower cost applications |

Introduction to Alkali Sizing and Acid Sizing

Alkali sizing involves treating paper fibers with alkaline compounds, such as rosin or alkyl ketene dimer (AKD), to improve water resistance and strength under basic conditions, making it suitable for neutral or alkaline papermaking processes. Acid sizing uses acidic substances like rosin in the presence of alum to enhance paper's resistance to water and ink, traditionally favored in acidic papermaking environments. The choice between alkali and acid sizing significantly impacts the paper's durability, printability, and environmental compatibility in industrial applications.

Definition and Basic Principles

Alkali sizing involves treating paper fibers with alkaline substances like sodium hydroxide to improve strength and printability, promoting better fiber bonding and resistance to water. Acid sizing uses acidic agents such as alum and rosin to impart hydrophobic properties, enhancing surface sizing for ink retention and water repellency. The fundamental difference lies in their pH environment: alkali sizing operates in a neutral to alkaline pH, while acid sizing requires an acidic pH, influencing the paper's durability and usability.

Historical Evolution of Sizing Methods

Alkali sizing emerged in the early 20th century as the primary method for improving paper strength by applying starch and other polymers under alkaline conditions, which enhanced retention and durability. Acid sizing followed, dominating mid-century due to its superior resistance to water penetration in acidic papermaking environments, though it caused long-term paper degradation. Your choice between alkali and acid sizing reflects advancements in chemical formulations and environmental considerations that have shaped the historical evolution of sizing techniques in papermaking.

Chemical Composition and Mechanisms

Alkali sizing utilizes cationic starches and synthetic polymers that bond through electrostatic attraction to impart water resistance by forming a hydrophobic layer on cellulose fibers, primarily in alkaline papermaking processes. Acid sizing employs rosin acids combined with alum (aluminum sulfate) to produce insoluble aluminum rosinate, which adheres to fibers and reduces wettability, functioning optimally at low pH levels. The chemical mechanism of alkali sizing centers on adsorption and film formation under alkaline conditions, whereas acid sizing relies on precipitation reactions and chemical retention within an acidic environment.

Process Differences: Alkali vs Acid Sizing

Alkali sizing involves treating paper fibers with alkaline substances such as rosin and soda ash, promoting water resistance and improved strength under neutral or basic pH conditions, while acid sizing utilizes acidic agents like alum and rosin to enhance surface sizing primarily in acidic environments. The alkali sizing process typically results in higher durability and resistance to environmental degradation compared to acid sizing, which may cause paper brittleness over time due to acid hydrolysis. Process control in alkali sizing requires maintaining pH above 7, whereas acid sizing demands precise pH regulation below 7 to optimize resin precipitation and sizing efficiency.

Impact on Paper Properties

Alkali sizing enhances paper strength and durability by improving fiber bonding and increasing resistance to water penetration, resulting in high-quality, writable paper suitable for printing. Acid sizing, typically using rosin and alum, imparts good initial water repellency but can lead to paper brittleness and decreased longevity due to acid-induced degradation over time. The choice between alkali and acid sizing significantly influences paper pH, brightness retention, and archival stability, making alkali sizing preferable for long-lasting, acid-free paper products.

Environmental Implications

Alkali sizing typically involves synthetic resins that can release harmful substances, posing risks to aquatic ecosystems and complicating wastewater treatment compared to acid sizing, which uses natural or less toxic chemicals like rosin and alum. Your choice of sizing method impacts environmental compliance since acid sizing yields biodegradable byproducts and reduces the carbon footprint associated with chemical production. Sustainable paper manufacturing increasingly favors acid sizing due to its lower environmental impact and enhanced recyclability of the paper products.

Cost and Resource Considerations

Alkali sizing typically incurs lower initial costs due to simpler chemical formulations and easier handling compared to acid sizing, which often requires more expensive acid-resistant equipment and chemicals. Resource consumption varies as alkali sizing uses alkaline compounds that can be sourced more sustainably, whereas acid sizing demands strong acids, increasing environmental and safety management expenses. Your choice between alkali and acid sizing should factor in both the upfront investment and long-term operational costs related to resource usage and waste treatment.

Industrial Applications and Suitability

Alkali sizing is predominantly used in the production of alkaline papers and packaging materials due to its enhanced resistance to water and increased durability, making it suitable for industrial applications requiring strong, moisture-resistant products. Acid sizing is favored in applications such as fine art paper and certain printing papers where high brightness and smoothness are essential, though it offers less moisture resistance and is less environmentally stable. Industrial suitability depends on the end-use, with alkali sizing preferred for packaging and commercial applications, and acid sizing chosen for specialty papers requiring superior printability and surface qualities.

Future Trends in Sizing Technologies

Future trends in sizing technologies reveal a shift toward sustainable and bio-based alkali sizing agents, enhancing paper machine efficiency and product durability while reducing environmental impact. Innovations in acid sizing focus on developing acid-free or neutral sizing compounds to improve recyclability and comply with stringent environmental regulations. Advanced nanotechnology and enzyme-based sizing methods are emerging to optimize surface strength and printability, indicating a transformative approach in the paper industry's future.

Alkali sizing vs acid sizing Infographic

libmatt.com

libmatt.com