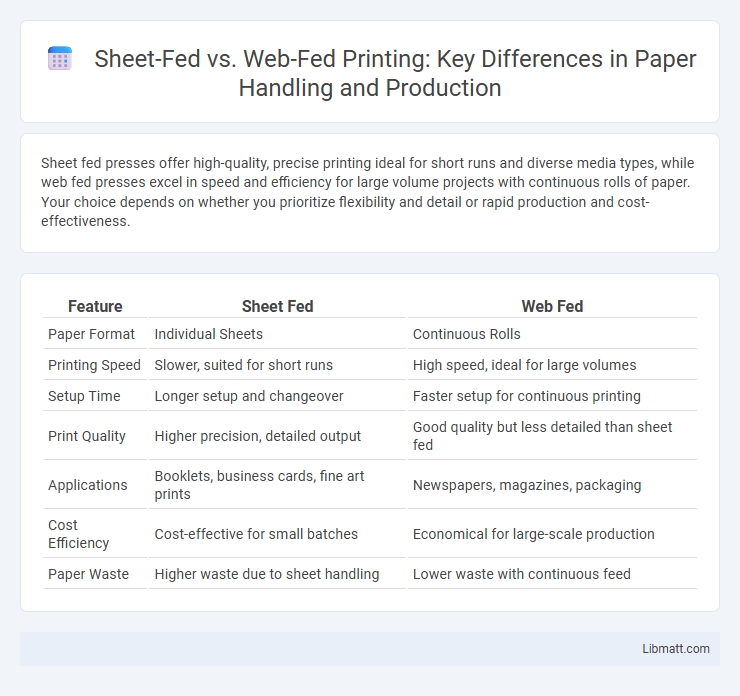

Sheet fed presses offer high-quality, precise printing ideal for short runs and diverse media types, while web fed presses excel in speed and efficiency for large volume projects with continuous rolls of paper. Your choice depends on whether you prioritize flexibility and detail or rapid production and cost-effectiveness.

Table of Comparison

| Feature | Sheet Fed | Web Fed |

|---|---|---|

| Paper Format | Individual Sheets | Continuous Rolls |

| Printing Speed | Slower, suited for short runs | High speed, ideal for large volumes |

| Setup Time | Longer setup and changeover | Faster setup for continuous printing |

| Print Quality | Higher precision, detailed output | Good quality but less detailed than sheet fed |

| Applications | Booklets, business cards, fine art prints | Newspapers, magazines, packaging |

| Cost Efficiency | Cost-effective for small batches | Economical for large-scale production |

| Paper Waste | Higher waste due to sheet handling | Lower waste with continuous feed |

Introduction to Sheet Fed and Web Fed Printing

Sheet fed printing processes individual sheets of paper through the press, ideal for short runs and high-quality prints with precise color control. Web fed printing utilizes continuous rolls of paper, enabling high-speed production suited for large volume jobs like newspapers, catalogs, and direct mail. Your choice between sheet fed and web fed depends on the project's scale, turnaround time, and budget efficiency.

Key Differences Between Sheet Fed and Web Fed

Sheet fed presses process individual sheets of paper, offering superior print quality and versatility for short runs and high-detail jobs. Web fed presses use continuous rolls of paper, enabling faster production speeds and cost efficiency in large-volume printing. Understanding these key differences helps you select the best printing method based on your project's size, speed, and quality requirements.

Advantages of Sheet Fed Printing

Sheet fed printing offers superior image quality and color accuracy, making it ideal for high-end marketing materials and professional publications. It allows for quick job changes and customization with minimal waste, enhancing efficiency for short to medium print runs. This method supports a wide range of paper thicknesses and finishes, providing versatility in product design and presentation.

Benefits of Web Fed Printing

Web fed printing enables high-speed production with continuous rolls of paper, significantly increasing output efficiency for large-volume jobs. It offers superior cost-effectiveness and reduced waste compared to sheet fed printing, making it ideal for newspapers, magazines, and extensive direct mail campaigns. The seamless operation of web fed presses also allows for faster turnaround times and enhanced color consistency across lengthy print runs.

Ideal Applications for Sheet Fed Printing

Sheet fed printing excels in short to medium print runs where high-quality, precise color reproduction is essential, making it ideal for brochures, business cards, and packaging prototypes. Its flexibility in handling various paper sizes and weights suits custom jobs requiring detailed image fidelity and quick turnaround times. This method is preferred for jobs that demand frequent plate changes, variable data printing, and high-end finishes such as embossing or foiling.

Best Uses for Web Fed Printing

Web fed printing excels in high-volume applications such as newspapers, magazines, catalogs, and packaging materials due to its continuous roll of paper that enables faster production speeds. It is ideal for long runs where consistent quality and rapid turnaround are essential, especially in commercial printing environments requiring large-scale output. The ability to handle various substrates and integrate advanced finishing processes further enhances its suitability for mass-market publications and promotional materials.

Cost Considerations: Sheet Fed vs Web Fed

Sheet fed printing generally involves higher setup costs due to individual sheet handling and slower production speeds, making it less cost-effective for large volume runs. Web fed printing offers lower per-unit costs in high-volume projects by continuously feeding rolls of paper, reducing downtime and waste. Businesses targeting mass production prioritize web fed processes to optimize cost efficiency and increase output.

Print Quality Comparison

Sheet-fed printing delivers superior print quality due to precise paper handling and consistent ink application, making it ideal for high-resolution images and detailed graphics. Web-fed printing, while faster and more cost-effective for large volumes, may exhibit slight variations in ink density and alignment, affecting overall sharpness. Advances in web-fed technology have narrowed the quality gap but sheet-fed remains preferred for premium print finishes.

Production Speed and Efficiency

Sheet-fed presses excel in short-run jobs with high print quality but operate at slower speeds, typically up to 18,000 sheets per hour. Web-fed presses, designed for high-volume printing, achieve much higher production speeds, often exceeding 60,000 feet per minute, significantly boosting efficiency for long print runs. Efficiency in web-fed systems is enhanced by continuous roll feeding, reducing downtime and waste compared to the sheet-by-sheet feeding of sheet-fed presses.

Choosing the Right Printing Method for Your Project

Sheet fed printing offers precise color control and high-quality output for shorter print runs and diverse substrates, making it ideal for detailed projects and small to medium volumes. Web fed printing excels in high-speed production and cost-efficiency for large-scale runs, perfect for newspapers, magazines, and bulk packaging. Understanding your project's print volume, color complexity, and turnaround time will help you choose the most effective method.

Sheet fed vs web fed Infographic

libmatt.com

libmatt.com