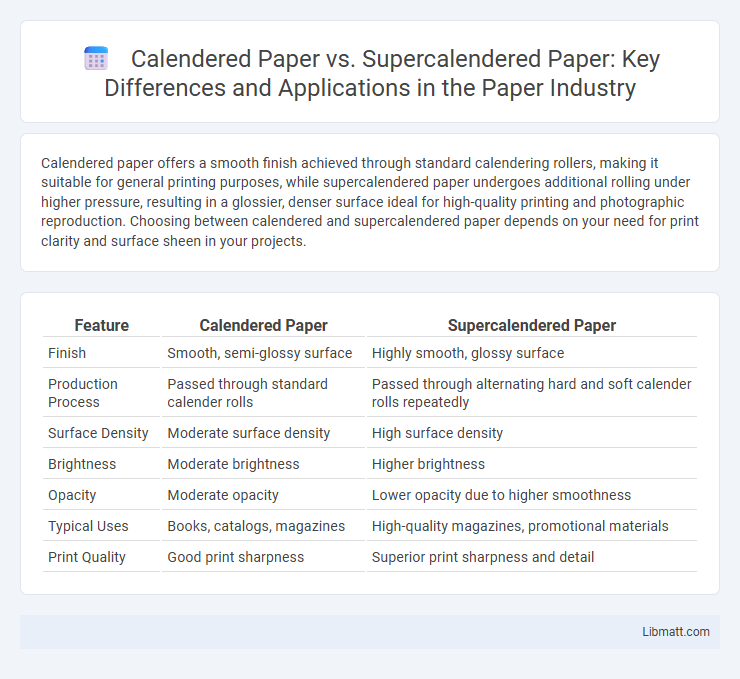

Calendered paper offers a smooth finish achieved through standard calendering rollers, making it suitable for general printing purposes, while supercalendered paper undergoes additional rolling under higher pressure, resulting in a glossier, denser surface ideal for high-quality printing and photographic reproduction. Choosing between calendered and supercalendered paper depends on your need for print clarity and surface sheen in your projects.

Table of Comparison

| Feature | Calendered Paper | Supercalendered Paper |

|---|---|---|

| Finish | Smooth, semi-glossy surface | Highly smooth, glossy surface |

| Production Process | Passed through standard calender rolls | Passed through alternating hard and soft calender rolls repeatedly |

| Surface Density | Moderate surface density | High surface density |

| Brightness | Moderate brightness | Higher brightness |

| Opacity | Moderate opacity | Lower opacity due to higher smoothness |

| Typical Uses | Books, catalogs, magazines | High-quality magazines, promotional materials |

| Print Quality | Good print sharpness | Superior print sharpness and detail |

Introduction to Calendered and Supercalendered Paper

Calendered paper is produced by passing the paper web through a series of rollers to achieve a smooth, glossy surface and uniform thickness, commonly used for high-quality printing and packaging. Supercalendered paper undergoes an extended calendering process with alternating hard and soft rollers, resulting in an even smoother, higher-density finish ideal for magazines, catalogs, and brochures. The key difference lies in the finish and surface properties, where supercalendered paper offers enhanced gloss, smoothness, and printability compared to standard calendered paper.

Definition and Manufacturing Process of Calendered Paper

Calendered paper is a type of coated paper that undergoes a finishing process using calender rolls to achieve a smooth and glossy surface, enhancing its print quality. The manufacturing process of calendered paper involves passing the paper web through a series of hard pressure rollers, which compress the fibers and improve surface uniformity and caliper control. This process differentiates calendered paper from supercalendered paper, which uses additional alternating hard and soft rollers for an even higher gloss and smoothness.

What is Supercalendered Paper?

Supercalendered paper is a type of finishing process applied to paper to create a smooth, glossy surface by compressing the fibers using a series of hard pressure rollers called supercalenders. This process enhances brightness, smoothness, and printability, making it ideal for high-quality publications, magazines, and catalogs compared to standard calendared paper, which has less gloss and smoothness. Your choice of supercalendered paper can significantly improve the visual appeal and tactile experience of printed materials.

Key Differences in Surface Finish

Calendered paper features a smooth surface achieved through moderate pressure rollers, providing a consistent finish suitable for general printing, while supercalendered paper undergoes additional high-pressure rolling between multiple alternating hard and soft rollers, resulting in a glossy, highly polished surface. This enhanced surface finish on supercalendered paper improves ink holdout and sharpness, making it ideal for high-quality image reproduction and fine text. Your choice depends on the desired print clarity and finish, with supercalendered paper offering superior brightness and smoothness compared to the more matte appearance of calendered paper.

Paper Smoothness and Gloss Comparison

Supercalendered paper exhibits higher smoothness and gloss compared to standard calendared paper due to the extended processing through alternating hard and soft rollers. This enhanced treatment produces a denser, more reflective surface ideal for high-quality printing applications. Calendared paper, while smooth, retains a slightly rougher texture and matte finish, making it suitable for less glossy print media.

Printability: Calendered vs. Supercalendered

Calendered paper features a smooth surface achieved through passing the paper web through a series of hard pressure rollers, enhancing printability by ensuring consistent ink absorption and sharp image reproduction. Supercalendered paper undergoes additional finishing with alternating hard and soft rollers, resulting in an ultra-smooth, glossy surface that improves print gloss and detail but may require specific inks to prevent smudging due to its reduced absorbency. Printability differences between calendered and supercalendered paper significantly impact the choice for applications like high-quality magazines and catalogs that demand superior visual appeal and ink adhesion.

Weight, Thickness, and Opacity Factors

Calendered paper typically has a higher weight and thickness compared to supercalendered paper, offering greater durability for printing applications. Supercalendered paper, known for its smoother and glossier finish, usually has lower opacity, making it suitable for magazines and brochures where image clarity is critical. Your choice between the two should balance the need for sturdiness with the desired visual effect, considering that calendered paper provides more opacity and thickness while supercalendered excels in surface smoothness.

Typical Applications in Printing Industry

Calendered paper is commonly used for high-quality printing applications such as magazines, brochures, and flyers where smoothness and gloss are essential but moderate cost is preferred. Supercalendered paper, featuring a higher gloss and smoother surface, is ideal for print jobs requiring superior image clarity and sharpness, including catalogs, advertising inserts, and premium publications. Your choice between these papers impacts print quality and tactile experience, influencing the visual appeal of marketing materials and product packaging.

Cost Considerations and Availability

Calendered paper generally incurs lower production costs due to simpler manufacturing processes, making it more affordable and widely available for standard printing needs. Supercalendered paper, subjected to additional smoothing and compressing stages, commands higher prices but offers superior surface finish suitable for high-quality printing applications. Availability of supercalendered paper can be more limited, often sourced from specialized suppliers, whereas calendered paper remains broadly accessible in various grades across global markets.

Choosing the Right Paper for Your Project

Calendered paper offers a smoother surface with moderate gloss, ideal for projects requiring sharp print quality and vibrant color reproduction. Supercalendered paper undergoes additional finishing, resulting in a higher gloss and even smoother texture, perfect for high-impact marketing materials or detailed imagery. Choosing the right paper for your project depends on your desired finish and budget, with calendered paper providing a cost-effective solution and supercalendered paper delivering superior aesthetic appeal.

Calendered paper vs supercalendered paper Infographic

libmatt.com

libmatt.com