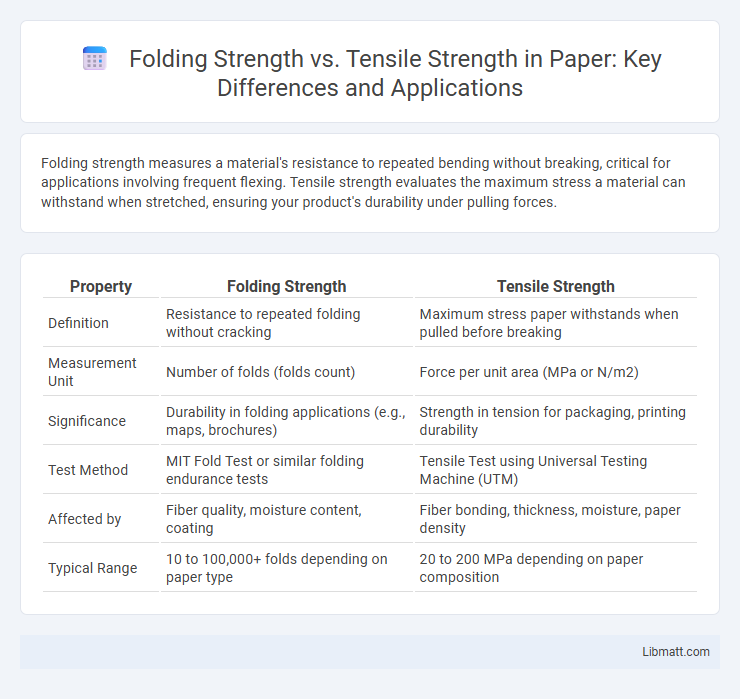

Folding strength measures a material's resistance to repeated bending without breaking, critical for applications involving frequent flexing. Tensile strength evaluates the maximum stress a material can withstand when stretched, ensuring your product's durability under pulling forces.

Table of Comparison

| Property | Folding Strength | Tensile Strength |

|---|---|---|

| Definition | Resistance to repeated folding without cracking | Maximum stress paper withstands when pulled before breaking |

| Measurement Unit | Number of folds (folds count) | Force per unit area (MPa or N/m2) |

| Significance | Durability in folding applications (e.g., maps, brochures) | Strength in tension for packaging, printing durability |

| Test Method | MIT Fold Test or similar folding endurance tests | Tensile Test using Universal Testing Machine (UTM) |

| Affected by | Fiber quality, moisture content, coating | Fiber bonding, thickness, moisture, paper density |

| Typical Range | 10 to 100,000+ folds depending on paper type | 20 to 200 MPa depending on paper composition |

Introduction to Folding Strength and Tensile Strength

Folding strength measures a material's ability to withstand repeated bending without breaking, which is crucial for products like paper and textiles that endure constant flexing. Tensile strength refers to the maximum stress a material can handle when stretched or pulled before breaking, important for construction materials and fabrics under tension. Understanding these two strengths helps you select the right material for durability and performance in applications involving bending or stretching forces.

Defining Folding Strength in Materials

Folding strength measures a material's ability to withstand repeated bending or folding without cracking or breaking, making it crucial for flexible products like paper and textiles. Tensile strength, by contrast, evaluates how much pulling force a material can endure before breaking, indicating its resistance to stretching. Understanding folding strength helps you select materials that maintain durability under cyclic stress, enhancing product longevity.

Understanding Tensile Strength Fundamentals

Tensile strength measures the maximum stress a material withstands while being stretched before breaking, reflecting its ability to resist pulling forces. Folding strength tests a material's resistance to repeated bending or creasing, which affects durability in applications like paper or fabric. Understanding tensile strength fundamentals is crucial for selecting materials in engineering and manufacturing, ensuring structural integrity under tension.

Key Differences Between Folding and Tensile Strength

Folding strength measures a material's resistance to repeated bending without cracking, primarily important in paper, cardboard, and textiles, while tensile strength quantifies the maximum stress a material can withstand when stretched before breaking. Folding strength depends on factors like fiber length and bonding, whereas tensile strength relates to molecular structure and material composition. Understanding these distinctions is crucial for selecting materials in packaging, printing, and manufacturing where flexibility or load-bearing capacity is prioritized.

Importance of Folding Strength in Engineering Applications

Folding strength is crucial in engineering applications involving flexible materials, as it determines how well a material withstands repeated bending without cracking or breaking. Unlike tensile strength, which measures resistance to pulling forces, folding strength directly impacts durability in products subjected to cyclic stress and dynamic loads. Engineers prioritize folding strength to ensure reliability and longevity in components such as packaging, wearable devices, and flexible electronics.

Significance of Tensile Strength in Material Selection

Tensile strength is a critical factor in material selection because it measures a material's ability to withstand pulling forces without breaking, directly impacting durability and performance in structural applications. While folding strength indicates resistance to repeated bending, tensile strength ensures that your material can endure intense stress and load-bearing conditions. Prioritizing tensile strength helps prevent material failure and extend the lifespan of products under tension.

Testing Methods for Folding and Tensile Strength

Folding strength is tested using methods like the MIT Folding Endurance Test, which measures the number of folds a material can withstand before breaking, while tensile strength is evaluated via tensile testing machines that apply controlled tension until the material fails. These tests provide critical data on the durability and elasticity of paper, textiles, and other materials under different stress conditions. Understanding your material's folding and tensile strength ensures optimized performance for applications requiring flexibility and resistance to tearing.

Factors Affecting Folding and Tensile Strength

Folding strength and tensile strength are influenced by factors such as material composition, fiber orientation, and moisture content. Paper with longer fibers and higher density generally exhibits greater folding strength, while tensile strength depends heavily on fiber bonding and internal cohesion. Environmental conditions like humidity also play crucial roles in altering the mechanical properties of both strengths.

Practical Examples: Where Folding vs Tensile Strength Matters

Folding strength is crucial in packaging materials like cardboard boxes, ensuring they withstand repeated bending without breaking during handling and shipping. Tensile strength is vital in applications such as seat belts and ropes, where the material must resist pulling forces to prevent snapping under load. Your choice between folding and tensile strength depends on whether the product faces bending stresses or direct tension in its practical use.

Conclusion: Choosing the Right Strength for Your Application

Folding strength measures a material's ability to withstand repeated bending without cracking, while tensile strength indicates how much pulling force it can endure before breaking. Selecting the right strength depends on your specific application requirements, such as flexibility or load-bearing capacity. Understanding these distinctions ensures optimal performance and durability in your projects.

folding strength vs tensile strength Infographic

libmatt.com

libmatt.com