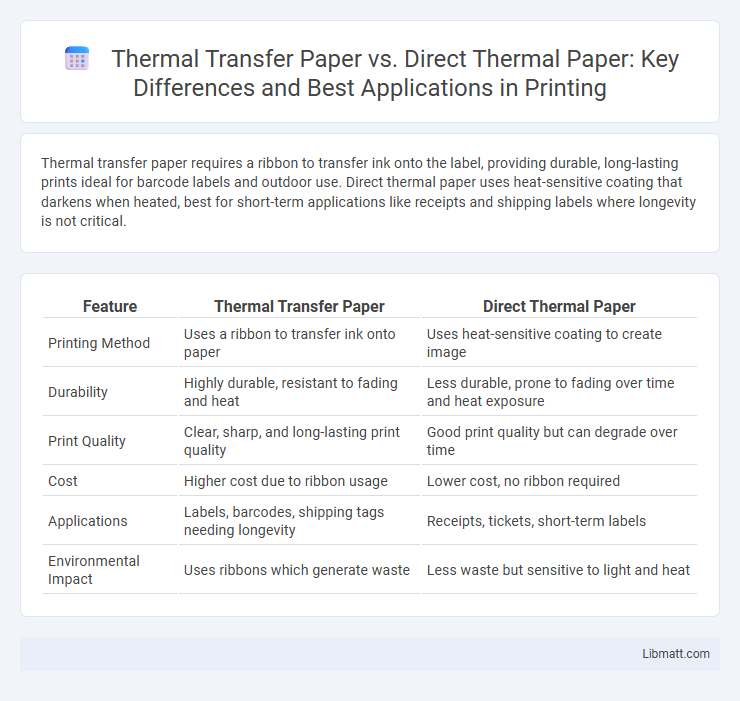

Thermal transfer paper requires a ribbon to transfer ink onto the label, providing durable, long-lasting prints ideal for barcode labels and outdoor use. Direct thermal paper uses heat-sensitive coating that darkens when heated, best for short-term applications like receipts and shipping labels where longevity is not critical.

Table of Comparison

| Feature | Thermal Transfer Paper | Direct Thermal Paper |

|---|---|---|

| Printing Method | Uses a ribbon to transfer ink onto paper | Uses heat-sensitive coating to create image |

| Durability | Highly durable, resistant to fading and heat | Less durable, prone to fading over time and heat exposure |

| Print Quality | Clear, sharp, and long-lasting print quality | Good print quality but can degrade over time |

| Cost | Higher cost due to ribbon usage | Lower cost, no ribbon required |

| Applications | Labels, barcodes, shipping tags needing longevity | Receipts, tickets, short-term labels |

| Environmental Impact | Uses ribbons which generate waste | Less waste but sensitive to light and heat |

Introduction to Thermal Transfer Paper and Direct Thermal Paper

Thermal transfer paper uses a ribbon coated with wax, resin, or a combination to produce durable, high-quality prints on various surfaces, making it ideal for long-lasting labels and barcodes. Direct thermal paper, by contrast, has a heat-sensitive coating that darkens when exposed to a thermal printhead, offering a simpler, ribbon-free printing process suitable for short-term applications like receipts or shipping labels. Your choice depends on durability needs, print quality requirements, and the printer type compatible with your operational workflow.

How Thermal Transfer Printing Works

Thermal transfer printing uses a heated printhead to melt ink from a ribbon onto the paper, creating durable and high-quality images resistant to fading and moisture. This method requires a thermal transfer ribbon that contains wax, resin, or a combination, which transfers the ink onto various label materials. Compared to direct thermal printing, thermal transfer offers greater longevity and is ideal for barcodes, labels, and tags needing extended durability.

How Direct Thermal Printing Works

Direct thermal printing works by applying heat directly to a specially coated thermal paper, causing the paper to change color without the need for ink or ribbon. The thermal layer contains heat-sensitive chemicals that react when exposed to the printer's heating element, creating precise and high-resolution images or text. This method is commonly used for receipts, labels, and shipping tags due to its simplicity and cost-effectiveness.

Key Differences Between Thermal Transfer and Direct Thermal Paper

Thermal transfer paper uses a ribbon to transfer ink onto the paper, producing durable, long-lasting prints ideal for labels exposed to heat or chemicals, while direct thermal paper relies on heat-sensitive coatings that darken when heated, resulting in quicker but less durable prints prone to fading. Your choice depends on label longevity, environmental exposure, and print quality requirements, with thermal transfer offering superior resistance and direct thermal offering faster, cost-effective solutions. Understanding these key differences guarantees optimal performance for your printing needs.

Durability and Longevity of Print

Thermal transfer paper produces prints with superior durability and longevity due to the use of a ribbon that applies ink, resulting in sharper, fade-resistant images ideal for long-term labeling. Direct thermal paper relies on heat-sensitive coated paper that darkens when heated, but the prints are more susceptible to fading, smudging, and damage from heat or light exposure. For applications requiring archival-quality or outdoor labels, thermal transfer printing ensures greater resistance to environmental factors and extended readability.

Cost Comparison: Thermal Transfer vs Direct Thermal

Thermal transfer paper requires a ribbon, increasing material costs compared to direct thermal paper, which uses heat-sensitive coating and eliminates ribbon expenses. Initial printer investment may be higher for thermal transfer systems due to the need for ribbon-compatible hardware, while direct thermal printers are typically more affordable. Over time, direct thermal printing offers lower operational costs but may incur higher replacement expenses due to label fading and shorter durability.

Best Use Cases for Each Paper Type

Thermal transfer paper excels in durable label printing for industrial environments, product labeling, and outdoor applications where longevity and resistance to heat, moisture, and chemicals are critical. Direct thermal paper suits short-term labeling needs such as receipts, shipping labels, and event tickets, where cost-effectiveness and high-speed printing are prioritized without the need for a ribbon. Selecting the appropriate paper type depends on the required print durability, environmental exposure, and expected label lifespan.

Environmental Impact and Sustainability

Thermal transfer paper requires a ribbon made of wax, resin, or a combination, generating more waste and using non-biodegradable materials, which can negatively impact sustainability efforts. Direct thermal paper eliminates the ribbon but relies on chemical coatings, often containing BPA or BPS, raising concerns about environmental toxicity and recycling challenges. Choosing recycled or BPA-free direct thermal paper and exploring eco-friendly ribbon alternatives can mitigate the environmental footprint of both methods.

Choosing the Right Thermal Printing Solution

Thermal transfer paper uses a ribbon to produce durable, long-lasting prints ideal for labels exposed to heat, moisture, or abrasion, while direct thermal paper relies on heat-sensitive coating and is suited for short-term applications like receipts and shipping labels. Selecting the right thermal printing solution depends on the intended use, environmental conditions, and label longevity required. Businesses needing high durability and resistance should opt for thermal transfer, whereas cost-effective, easy-to-use direct thermal offers efficiency for temporary labeling needs.

Frequently Asked Questions (FAQs)

Thermal transfer paper uses a ribbon to transfer ink onto the label, providing durable, long-lasting prints ideal for barcode labels and outdoor use, while direct thermal paper produces images directly on the heat-sensitive surface, suitable for short-term applications like receipts. Common FAQs include inquiries about print longevity, with thermal transfer paper lasting up to several years compared to direct thermal's susceptibility to fading within months. Users often ask about equipment costs, where thermal transfer requires a ribbon and typically higher initial investment, whereas direct thermal printers are more cost-effective but less durable.

thermal transfer paper vs direct thermal paper Infographic

libmatt.com

libmatt.com