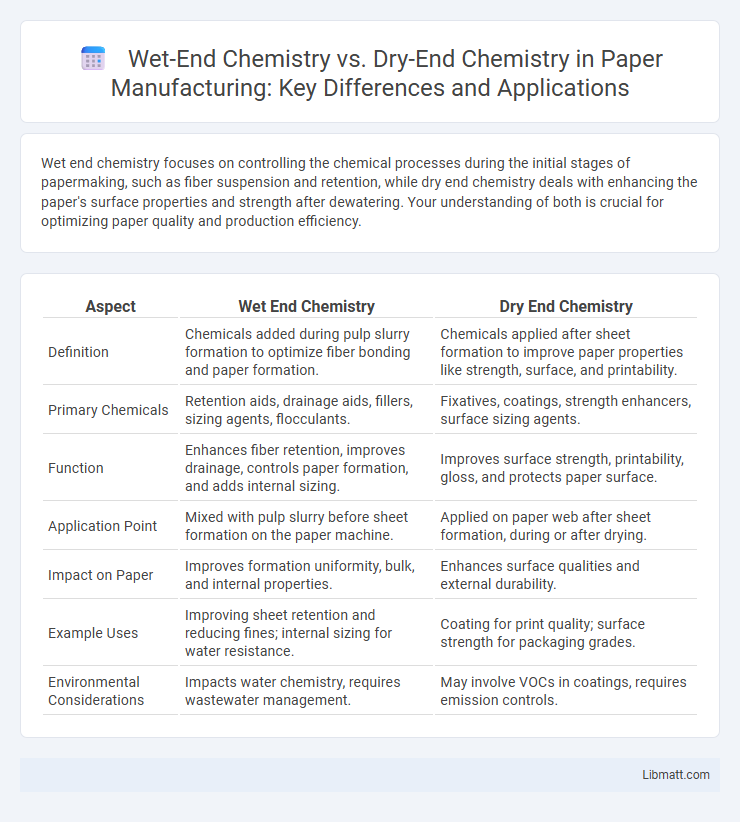

Wet end chemistry focuses on controlling the chemical processes during the initial stages of papermaking, such as fiber suspension and retention, while dry end chemistry deals with enhancing the paper's surface properties and strength after dewatering. Your understanding of both is crucial for optimizing paper quality and production efficiency.

Table of Comparison

| Aspect | Wet End Chemistry | Dry End Chemistry |

|---|---|---|

| Definition | Chemicals added during pulp slurry formation to optimize fiber bonding and paper formation. | Chemicals applied after sheet formation to improve paper properties like strength, surface, and printability. |

| Primary Chemicals | Retention aids, drainage aids, fillers, sizing agents, flocculants. | Fixatives, coatings, strength enhancers, surface sizing agents. |

| Function | Enhances fiber retention, improves drainage, controls paper formation, and adds internal sizing. | Improves surface strength, printability, gloss, and protects paper surface. |

| Application Point | Mixed with pulp slurry before sheet formation on the paper machine. | Applied on paper web after sheet formation, during or after drying. |

| Impact on Paper | Improves formation uniformity, bulk, and internal properties. | Enhances surface qualities and external durability. |

| Example Uses | Improving sheet retention and reducing fines; internal sizing for water resistance. | Coating for print quality; surface strength for packaging grades. |

| Environmental Considerations | Impacts water chemistry, requires wastewater management. | May involve VOCs in coatings, requires emission controls. |

Overview of Wet End and Dry End Chemistry

Wet end chemistry involves the chemical processes and additives applied during the initial stages of papermaking, focusing on fiber bonding, retention, drainage, and fill control to enhance sheet formation and strength. Dry end chemistry refers to treatments applied after sheet formation, such as sizing agents, surface coatings, and fixatives, which improve the paper's surface properties, printability, and durability. Both chemistries are crucial for optimizing paper quality, operational efficiency, and product performance in the papermaking industry.

Fundamental Differences Between Wet End and Dry End Processes

Wet end chemistry involves the manipulation of pulp and fiber suspension properties in aqueous solutions, focusing on additives such as retention aids, sizing agents, and flocculants that influence fiber bonding, drainage, and sheet formation. Dry end chemistry centers on surface treatment and finishing processes, including coating formulation, adhesive application, and surface strength enhancers that improve printability, gloss, and moisture resistance of the final paper product. The fundamental difference lies in wet end chemistry managing fiber interactions in the slurry phase, while dry end chemistry optimizes the paper surface and mechanical properties post-formation.

Key Chemical Reactions in the Wet End

Key chemical reactions in the wet end involve the interaction of fibers, fillers, and additives within the aqueous pulp suspension, where retention aids and flocculants play critical roles in fiber bonding and filler retention. You can observe the formation of hydrogen bonds, ionic interactions, and adsorption processes that directly influence sheet formation and paper strength. These wet end reactions set the foundation for the final paper properties before drying and calendering occur in the dry end.

Primary Functions of Dry End Chemistry

Dry end chemistry primarily enhances paper quality by improving surface properties such as smoothness, gloss, and printability through the application of coatings, binders, and additives. It stabilizes the paper web during drying and calendering processes to prevent defects like dusting and picking. Key chemicals include pigments, binders, sizing agents, and retention aids that ensure consistent finish and performance of the final paper product.

Major Additives Used in Wet End vs. Dry End

Major additives used in wet end chemistry include retention aids, flocculants, fillers like calcium carbonate, and biocides to improve fiber bonding, retention, and sheet formation. Dry end chemistry primarily involves sizing agents such as alkyl ketene dimer (AKD) and wax emulsions to enhance surface strength, water repellency, and printability. Your paper production process relies on optimizing these additive selections to balance performance and cost effectively.

Impact on Paper Quality and Performance

Wet end chemistry controls fiber bonding, retention, and drainage, directly influencing paper strength, formation, and smoothness. Dry end chemistry affects sheet drying, surface sizing, and calendering, enhancing surface properties such as gloss, printability, and stiffness. Optimizing both wet and dry end chemistries ensures balanced paper quality and performance, meeting specific functional and aesthetic requirements.

Control Strategies in Wet End Chemistry

Control strategies in wet end chemistry focus on optimizing pulp and paper formation by regulating fiber dispersion, retention aids, and charge balance to enhance sheet formation and strength. Key parameters such as pH, conductivity, and temperature are continuously monitored to maintain chemical dosages and minimize contaminants that disrupt flocculation and retention processes. Advanced control systems integrate real-time data analytics and feedback loops to adjust chemical inputs dynamically, improving process stability and product quality in the wet end stage.

Enhancing Efficiency Through Dry End Chemical Modifications

Dry end chemical modifications optimize the paper manufacturing process by improving sheet formation, enhancing surface properties, and reducing defects such as dusting and linting. These treatments increase paper strength, printability, and adhesive performance compared to wet end chemistry, which primarily focuses on fiber bonding and retention during early sheet formation. Implementing targeted dry end chemistries can significantly boost your production efficiency and final product quality by tailoring surface characteristics to specific application requirements.

Environmental Considerations in Both Processes

Wet end chemistry in papermaking primarily deals with water-based processes, requiring careful management of effluents and chemical additives to minimize environmental impact, such as reducing water pollution and chemical runoff. Dry end chemistry focuses on surface treatments and finishes that often involve volatile organic compounds (VOCs) and energy-intensive curing methods, which pose air quality and energy consumption concerns. Balancing these environmental considerations in both wet and dry end processes supports sustainable production and helps you achieve eco-friendly paper manufacturing goals.

Future Trends in Wet End and Dry End Chemistry

Future trends in wet end chemistry emphasize eco-friendly additives and bio-based polymers to enhance paper strength and retention while minimizing environmental impact. In dry end chemistry, innovations focus on advanced coating formulations and nano-particle technology to improve surface smoothness, printability, and moisture resistance. Integration of real-time monitoring and AI-driven process optimization is transforming both wet and dry end stages to boost efficiency and product quality in papermaking.

Wet end chemistry vs dry end chemistry Infographic

libmatt.com

libmatt.com