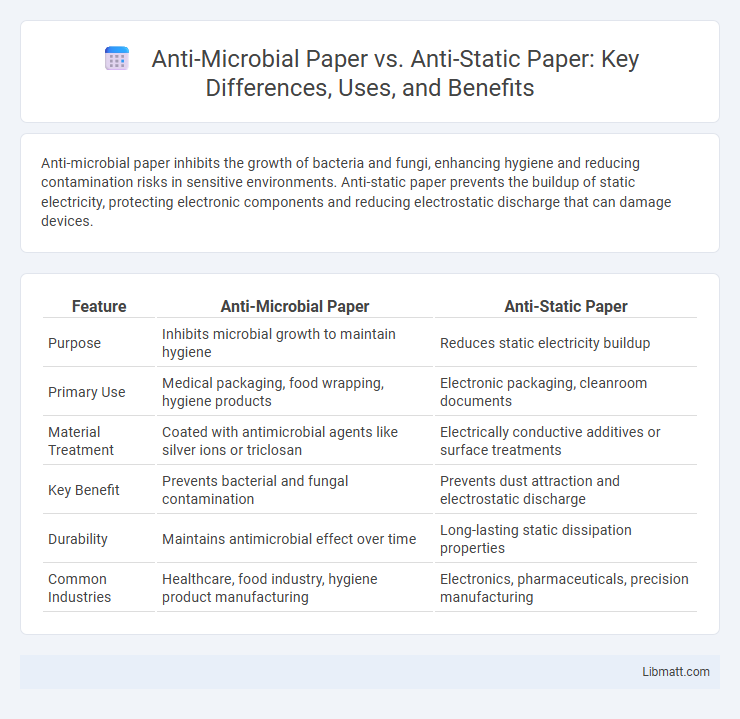

Anti-microbial paper inhibits the growth of bacteria and fungi, enhancing hygiene and reducing contamination risks in sensitive environments. Anti-static paper prevents the buildup of static electricity, protecting electronic components and reducing electrostatic discharge that can damage devices.

Table of Comparison

| Feature | Anti-Microbial Paper | Anti-Static Paper |

|---|---|---|

| Purpose | Inhibits microbial growth to maintain hygiene | Reduces static electricity buildup |

| Primary Use | Medical packaging, food wrapping, hygiene products | Electronic packaging, cleanroom documents |

| Material Treatment | Coated with antimicrobial agents like silver ions or triclosan | Electrically conductive additives or surface treatments |

| Key Benefit | Prevents bacterial and fungal contamination | Prevents dust attraction and electrostatic discharge |

| Durability | Maintains antimicrobial effect over time | Long-lasting static dissipation properties |

| Common Industries | Healthcare, food industry, hygiene product manufacturing | Electronics, pharmaceuticals, precision manufacturing |

Introduction to Specialty Papers: Anti-Microbial vs. Anti-Static

Specialty papers serve unique functions in various industries, with anti-microbial paper designed to inhibit bacterial growth and enhance hygiene, while anti-static paper prevents static electricity buildup to protect sensitive electronic components. Anti-microbial paper incorporates agents like silver ions or copper compounds that disrupt microbial cell membranes, making it ideal for healthcare and food packaging applications. Your choice between these papers depends on whether microbial resistance or electrostatic discharge prevention better suits your specific needs.

Defining Anti-Microbial Paper: Mechanisms and Benefits

Anti-microbial paper incorporates agents that inhibit the growth of bacteria, fungi, and other microorganisms on its surface, providing a hygienic barrier crucial for medical, food packaging, and sanitation applications. These agents work through mechanisms such as releasing biocides, disrupting microbial cell walls, or preventing adhesion, significantly reducing contamination risks and extending product lifespan. Your choice of anti-microbial paper ensures enhanced safety and durability in environments prone to microbial exposure, distinguishing it from anti-static paper that targets electrical charge reduction rather than microbial control.

Understanding Anti-Static Paper: Functions and Applications

Anti-static paper is specially designed to prevent the buildup of static electricity, protecting sensitive electronic components during manufacturing and packaging. Its surface resists electrostatic discharge (ESD), making it essential for use in electronics assembly, cleanrooms, and environments prone to static damage. Understanding your needs for static control can help you choose anti-static paper to safeguard delicate devices and maintain product integrity.

Key Differences Between Anti-Microbial and Anti-Static Papers

Anti-microbial paper is treated with agents that inhibit the growth of bacteria, fungi, and other microbes, ensuring hygiene and reducing contamination risks in medical or food packaging applications. Anti-static paper, on the other hand, is designed to prevent the buildup of static electricity, protecting sensitive electronic components and preventing dust attraction. The key differences lie in their functional properties: microbial inhibition for anti-microbial paper versus electrostatic discharge prevention for anti-static paper.

Common Uses of Anti-Microbial Paper in Various Industries

Anti-microbial paper is widely used in healthcare settings for medical packaging and disposable items to prevent the spread of bacteria and infections. The food industry utilizes this paper for sanitary packaging and wrapping to maintain hygiene and extend shelf life. In the hospitality sector, anti-microbial paper is applied in menus, hotel stationery, and surface covers to enhance cleanliness and safety for guests.

Applications of Anti-Static Paper in Modern Workplaces

Anti-static paper is essential in modern workplaces such as electronics manufacturing and laboratories where static discharge can damage sensitive components or disrupt experiments. Its applications include packaging for static-sensitive devices, protective work surfaces, and documentation that prevents electrostatic build-up. You benefit from enhanced safety and reduced risk of equipment failure in environments prone to static electricity exposure.

Material Composition and Manufacturing Techniques

Anti-microbial paper incorporates additives like silver ions, triclosan, or zinc oxide into cellulose fibers during manufacturing to inhibit microbial growth on its surface. Anti-static paper is typically treated with conductive or dissipative coatings or integrated with carbon-based fillers to prevent static electricity buildup. You can choose between these papers based on their material properties and production methods aligned with your application needs.

Safety, Compliance, and Regulatory Standards

Anti-microbial paper provides enhanced safety by inhibiting the growth of harmful bacteria and viruses, making it ideal for healthcare and food packaging industries that demand strict hygiene compliance. Anti-static paper is essential in electronics manufacturing, preventing static discharge that could damage sensitive components, ensuring compliance with industry regulations such as IEC 61340-5-1. Your choice between these papers should consider the specific regulatory standards relevant to your application to maintain safety and meet compliance requirements effectively.

Environmental Impact and Sustainability Considerations

Anti-microbial paper is treated with biocidal agents that can pose environmental risks during degradation, potentially releasing harmful substances into ecosystems; sustainable alternatives prioritize natural antimicrobial substances to reduce ecological footprints. Anti-static paper, often coated with chemicals to prevent static electricity, may involve synthetic compounds that are less biodegradable, raising concerns about long-term soil and water contamination. Choosing eco-friendly production methods and biodegradable treatments for both paper types enhances sustainability by minimizing toxic residues and supporting circular economy practices.

Choosing the Right Specialty Paper: Factors to Consider

Selecting the right specialty paper depends on the specific application requirements such as hygiene and static control. Anti-microbial paper is ideal for medical and food packaging environments due to its bacteria-inhibiting properties, while anti-static paper suits electronics manufacturing and cleanrooms where preventing static discharge is critical. Consider factors like durability, regulatory compliance, and environmental impact to ensure optimal performance and safety.

Anti-microbial paper vs anti-static paper Infographic

libmatt.com

libmatt.com