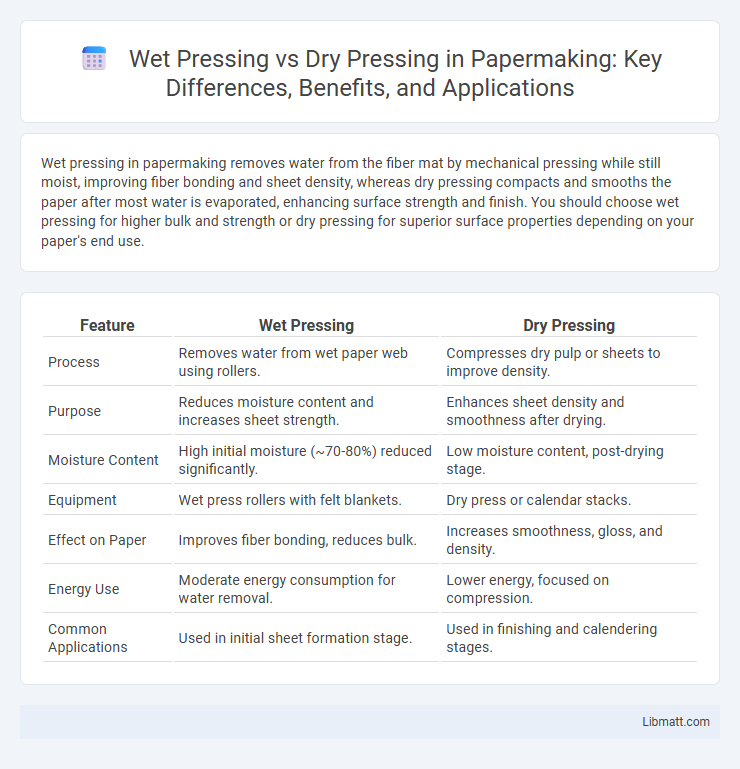

Wet pressing in papermaking removes water from the fiber mat by mechanical pressing while still moist, improving fiber bonding and sheet density, whereas dry pressing compacts and smooths the paper after most water is evaporated, enhancing surface strength and finish. You should choose wet pressing for higher bulk and strength or dry pressing for superior surface properties depending on your paper's end use.

Table of Comparison

| Feature | Wet Pressing | Dry Pressing |

|---|---|---|

| Process | Removes water from wet paper web using rollers. | Compresses dry pulp or sheets to improve density. |

| Purpose | Reduces moisture content and increases sheet strength. | Enhances sheet density and smoothness after drying. |

| Moisture Content | High initial moisture (~70-80%) reduced significantly. | Low moisture content, post-drying stage. |

| Equipment | Wet press rollers with felt blankets. | Dry press or calendar stacks. |

| Effect on Paper | Improves fiber bonding, reduces bulk. | Increases smoothness, gloss, and density. |

| Energy Use | Moderate energy consumption for water removal. | Lower energy, focused on compression. |

| Common Applications | Used in initial sheet formation stage. | Used in finishing and calendering stages. |

Introduction to Wet Pressing and Dry Pressing in Papermaking

Wet pressing in papermaking involves applying mechanical pressure to the wet fiber mat to remove water, enhancing sheet formation and improving paper density and smoothness. Dry pressing removes moisture from partially dried sheets using heated rollers, increasing drying efficiency and strength by consolidating fibers without damaging the material. Your choice between wet and dry pressing impacts the paper's texture, strength, and production speed, crucial factors for various paper grades and applications.

Fundamental Principles of Wet Pressing

Wet pressing in papermaking relies on mechanically compressing the moist paper web to remove water and increase fiber bonding, significantly enhancing paper strength and smoothness. This process exploits the plasticity of fibers in the presence of water to compact and align them efficiently, whereas dry pressing primarily removes water using heat and pressure without the same level of fiber bonding improvement. Understanding the fundamental principles of wet pressing helps optimize Your paper production by balancing moisture content and pressing pressure for maximum sheet formation quality.

Key Processes Involved in Dry Pressing

Dry pressing in papermaking involves mechanically compressing the paper web to remove water through pressure rather than heat, enhancing fiber bonding and improving paper density and smoothness. Key processes include passing the wet paper sheet through a press nip between rollers, which physically squeezes out water, reducing moisture content before drying. Your control over pressing pressure and speed directly affects paper quality, influencing caliper, tensile strength, and surface properties.

Differences in Equipment Used for Wet and Dry Pressing

Wet pressing in papermaking utilizes heavy, water-permeable felts and large, cylindrical or flat presses designed to remove water from the paper web through mechanical pressure, relying on consistent moisture content. Dry pressing employs heated rollers or dryers that apply pressure and heat simultaneously to reduce moisture and improve sheet density and strength. The key difference lies in wet pressing's emphasis on water extraction using absorbent felts and mechanical pressure, while dry pressing combines heat and pressure without felts to achieve moisture reduction and surface finishing.

Impact on Paper Properties: Wet vs. Dry Pressing

Wet pressing in papermaking improves fiber bonding and reduces porosity, resulting in stronger, denser paper with enhanced smoothness and printability. Dry pressing, meanwhile, often leads to higher bulk and porosity but lower strength, affecting the paper's absorbency and texture. Your choice between wet and dry pressing directly influences the final paper's durability, surface quality, and suitability for specific applications.

Energy Consumption Comparison

Wet pressing in papermaking typically consumes less energy compared to dry pressing because it uses mechanical pressure to remove water from the paper fiber mat while it is still wet, reducing the need for extensive drying energy. Dry pressing requires significant thermal energy to evaporate moisture after initial pressing, leading to higher overall energy consumption. Understanding this comparison helps you optimize your papermaking process for improved energy efficiency and cost savings.

Effects on Paper Strength and Quality

Wet pressing in papermaking significantly enhances paper strength by effectively removing water, which compacts fibers and improves fiber bonding, resulting in denser, stronger sheets. Dry pressing, on the other hand, may preserve more surface texture but generally produces paper with lower tensile strength because it lacks the intensive compression needed to align fibers tightly. The choice between wet and dry pressing directly influences paper quality parameters such as smoothness, brightness, and durability, with wet pressing favored for high-strength, high-quality paper products.

Suitability for Various Paper Grades

Wet pressing is highly suitable for producing high-quality, smooth paper grades such as printing and writing papers due to its ability to effectively remove water and improve fiber bonding. Dry pressing is more appropriate for coarser paper grades like newsprint and packaging materials, where rapid drying and bulk retention are prioritized over surface finish. The choice between wet and dry pressing directly impacts the final paper characteristics, including strength, texture, and printability.

Environmental Considerations in Wet and Dry Pressing

Wet pressing in papermaking uses significant water volumes, leading to higher energy consumption for drying and water treatment, impacting environmental footprint. Dry pressing greatly reduces water usage, decreasing wastewater generation and energy demand, contributing to more sustainable production. Your choice between wet and dry pressing influences resource efficiency and environmental sustainability in paper manufacturing.

Selecting the Optimal Pressing Method in Papermaking

Selecting the optimal pressing method in papermaking depends on the desired paper quality and production efficiency. Wet pressing enhances water removal from the fiber web, improving sheet formation and mechanical strength, while dry pressing is suited for materials with higher solids content, reducing energy consumption during drying. Understanding your specific paper grade and production goals ensures the choice between wet and dry pressing maximizes product performance and process sustainability.

Wet pressing vs dry pressing (in papermaking) Infographic

libmatt.com

libmatt.com