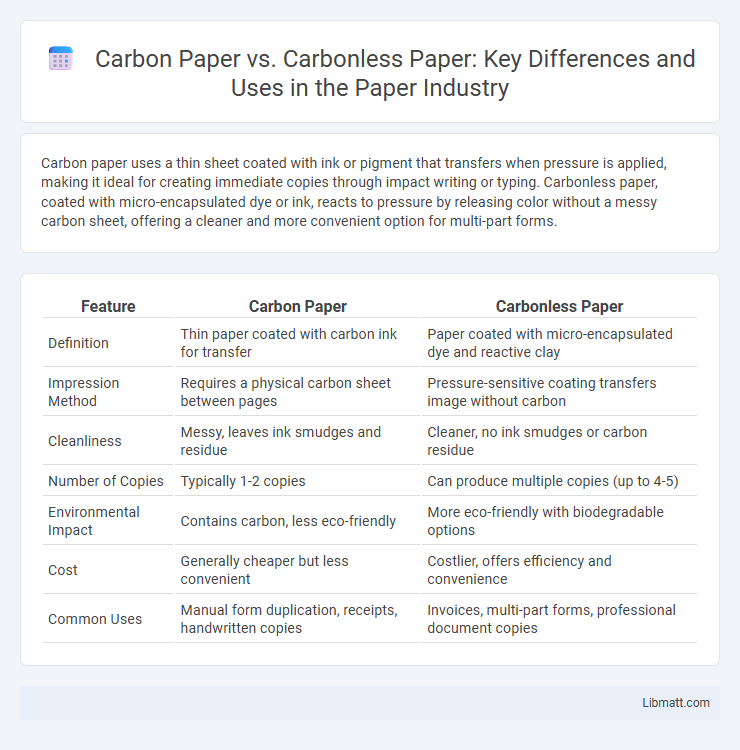

Carbon paper uses a thin sheet coated with ink or pigment that transfers when pressure is applied, making it ideal for creating immediate copies through impact writing or typing. Carbonless paper, coated with micro-encapsulated dye or ink, reacts to pressure by releasing color without a messy carbon sheet, offering a cleaner and more convenient option for multi-part forms.

Table of Comparison

| Feature | Carbon Paper | Carbonless Paper |

|---|---|---|

| Definition | Thin paper coated with carbon ink for transfer | Paper coated with micro-encapsulated dye and reactive clay |

| Impression Method | Requires a physical carbon sheet between pages | Pressure-sensitive coating transfers image without carbon |

| Cleanliness | Messy, leaves ink smudges and residue | Cleaner, no ink smudges or carbon residue |

| Number of Copies | Typically 1-2 copies | Can produce multiple copies (up to 4-5) |

| Environmental Impact | Contains carbon, less eco-friendly | More eco-friendly with biodegradable options |

| Cost | Generally cheaper but less convenient | Costlier, offers efficiency and convenience |

| Common Uses | Manual form duplication, receipts, handwritten copies | Invoices, multi-part forms, professional document copies |

Introduction to Carbon Paper and Carbonless Paper

Carbon paper is a thin sheet coated with a layer of carbon or pigmented material used to create duplicate copies by placing it between two sheets of paper and applying pressure from writing or typing. Carbonless paper, also known as self-copy paper or NCR paper, uses micro-encapsulated dye and clay coatings that react chemically when pressure is applied, eliminating the need for a separate carbon sheet. Both types serve as traditional methods for producing multiple document copies, with carbonless paper offering a cleaner and more convenient alternative.

History and Development of Copying Papers

Carbon paper, invented in the early 19th century, revolutionized document duplication by placing a wax-based ink sheet between papers to create copies through pressure. Carbonless paper emerged in the mid-20th century as a cleaner, more efficient alternative using micro-encapsulated dye that reacts upon impact, eliminating the need for messy carbon sheets. Your choice between these papers can depend on the historical context and specific copying needs of your business or personal use.

Composition and Mechanism of Carbon Paper

Carbon paper consists of a thin sheet coated with a layer of pigmented wax or ink on one side, which transfers marks through pressure. When pressure is applied by writing or typing, the pigment on the back of the carbon paper is transferred onto the underlying sheet, creating a copy. This mechanism relies on the physical transfer of ink particles, distinguishing it from carbonless paper, which uses micro-encapsulated dye and clay-based reactive layers to form copies chemically.

How Carbonless Paper Works

Carbonless paper works by using micro-encapsulated dye or ink on the back of the top sheet, which breaks and reacts with a clay coating on the front of the sheet below when pressure is applied, creating a copy without the need for carbon. This chemical reaction transfers the written or printed information, providing clean, instant duplicates without the smudging issues associated with traditional carbon paper. Your choice between carbon and carbonless paper depends on the need for convenience and environmental considerations in document duplication.

Key Differences Between Carbon Paper and Carbonless Paper

Carbon paper requires a separate sheet coated with carbon pigment to transfer writing or typing impressions to the underlying paper, while carbonless paper uses micro-encapsulated dye or ink that reacts chemically when pressure is applied, creating a copy without additional materials. Carbon paper can be messy and leaves residual marks, whereas carbonless paper provides a cleaner, more efficient copying process ideal for multi-part forms. Your choice depends on the need for convenience, environmental concerns, and the nature of the document handling.

Environmental Impact of Both Paper Types

Carbon paper contains a dye layer that can release hazardous chemicals during production and disposal, making it less eco-friendly compared to carbonless paper. Carbonless paper uses micro-encapsulated dyes and clay coatings, which reduce chemical waste and improve recyclability, minimizing environmental impact. Your choice of carbonless paper supports a greener office by limiting toxic waste and promoting sustainable paper use.

Common Applications in Modern Industries

Carbon paper is widely used in industries like automotive repair and legal documentation for creating instant copies through pressure transfer, making it ideal for manual forms and invoices. Carbonless paper, favored in healthcare and financial sectors, enables multi-part forms without messy smudging, enhancing record-keeping and transaction accuracy. Both materials support efficient documentation processes, but carbonless paper's environmentally friendly, dye-saturated microcapsule technology makes it preferable for high-volume, clean-copy requirements.

Advantages and Disadvantages of Carbon Paper

Carbon paper offers clear advantages such as producing sharp, immediate duplicates and compatibility with various writing instruments, but it requires manual placement and can be messy due to ink smudging. Its durability allows multiple copies with good legibility, however, it can wear down quickly and is less environmentally friendly compared to carbonless paper. Your choice depends on whether you prioritize traditional, tactile feedback or seek a cleaner, more eco-friendly duplication method.

Pros and Cons of Using Carbonless Paper

Carbonless paper offers the advantage of producing multiple copies without the mess of carbon residue, making it environmentally friendlier and more convenient for handling sensitive documents. Its main drawback is higher initial cost and potential difficulty in achieving perfect copy clarity on every sheet compared to traditional carbon paper. You benefit from cleaner, more efficient duplicate creation, but must consider the expense and specific use cases where carbonless paper excels.

Choosing the Right Paper for Your Business Needs

Carbon paper creates duplicate records through a waxy, ink-coated sheet placed between documents, ideal for low-volume, manual duplication tasks. Carbonless paper employs micro-encapsulated dye or ink that transfers when pressure is applied, providing an efficient, mess-free solution for high-volume, multi-part forms frequently used in invoices, receipts, and order forms. Choosing the right paper depends on your business's duplication volume, environmental concerns, and the need for clean, professional copies without the hassle of ink smudging or disposal issues.

Carbon paper vs carbonless paper Infographic

libmatt.com

libmatt.com