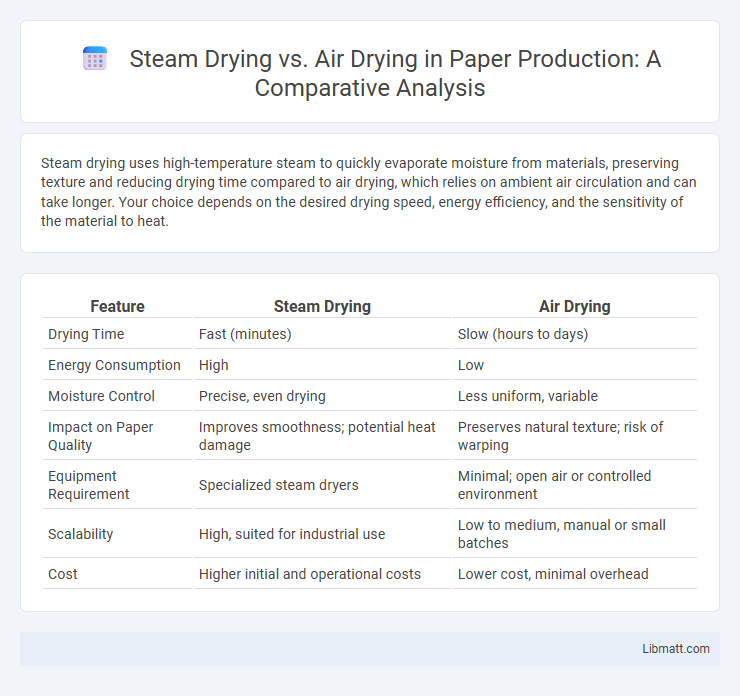

Steam drying uses high-temperature steam to quickly evaporate moisture from materials, preserving texture and reducing drying time compared to air drying, which relies on ambient air circulation and can take longer. Your choice depends on the desired drying speed, energy efficiency, and the sensitivity of the material to heat.

Table of Comparison

| Feature | Steam Drying | Air Drying |

|---|---|---|

| Drying Time | Fast (minutes) | Slow (hours to days) |

| Energy Consumption | High | Low |

| Moisture Control | Precise, even drying | Less uniform, variable |

| Impact on Paper Quality | Improves smoothness; potential heat damage | Preserves natural texture; risk of warping |

| Equipment Requirement | Specialized steam dryers | Minimal; open air or controlled environment |

| Scalability | High, suited for industrial use | Low to medium, manual or small batches |

| Cost | Higher initial and operational costs | Lower cost, minimal overhead |

Introduction to Steam Drying and Air Drying

Steam drying utilizes high-temperature steam to rapidly remove moisture from materials, significantly reducing drying time compared to traditional air drying methods. Air drying relies on natural or forced airflow at ambient or slightly elevated temperatures, making it energy-efficient but slower and vulnerable to environmental conditions. Your choice between steam drying and air drying depends on factors like drying speed, energy consumption, and the sensitivity of the materials involved.

How Steam Drying Works

Steam drying uses high-temperature steam to remove moisture from materials by vaporizing water content rapidly, which enhances drying efficiency compared to traditional methods. This process involves injecting steam directly or indirectly onto the product surface, facilitating quicker moisture evaporation without prolonged exposure to air. Steam drying reduces drying time and energy consumption, making it ideal for applications in food processing, pharmaceuticals, and textiles.

How Air Drying Works

Air drying works by exposing moisture-laden items to open air, allowing water to evaporate naturally from the surface. This process relies on ambient temperature, humidity, and airflow to facilitate evaporation without additional heat sources. Effective air drying reduces moisture content gradually, preserving material integrity while minimizing energy consumption compared to steam drying.

Efficiency Comparison: Steam vs Air Drying

Steam drying significantly outperforms air drying in efficiency by utilizing high-temperature steam to rapidly evaporate moisture, reducing drying time by up to 70%. Industrial steam drying systems maintain precise temperature control and uniform heat distribution, enhancing energy use and product quality compared to the slower, weather-dependent air drying. Energy consumption analysis reveals steam drying achieves higher throughput with lower overall operational costs, making it the preferred method for large-scale, time-sensitive drying applications.

Impact on Material Quality

Steam drying preserves material quality by maintaining moisture balance and reducing fiber damage, resulting in a softer and more durable texture compared to air drying. Air drying often leads to uneven drying and increased stiffness due to prolonged exposure to air and potential contaminants. You can achieve superior results with steam drying when consistent material integrity is crucial.

Energy Consumption Analysis

Steam drying consumes significantly more energy than air drying due to the need for generating high-temperature steam, typically requiring 3 to 5 times the energy input per kilogram of moisture removed. Air drying relies on ambient or mildly heated air, resulting in lower operational energy costs but longer drying times, which may affect throughput. Evaluating energy efficiency involves considering energy input per unit of moisture evaporated, where air drying often proves more sustainable for low-moisture applications, while steam drying remains effective for industrial-scale, high-throughput processes despite higher energy demands.

Environmental Considerations

Steam drying consumes less water and reduces energy usage compared to prolonged air drying, significantly lowering its environmental footprint. Air drying relies on natural airflow and solar energy, producing zero emissions but often requiring extended drying times that can increase greenhouse gas emissions if powered mechanically. Choosing between steam and air drying involves balancing energy efficiency, water conservation, and carbon emission impacts for sustainable drying practices.

Cost Implications

Steam drying generally incurs higher upfront costs due to specialized equipment and energy consumption compared to air drying, which primarily relies on ambient conditions with minimal expenses. Operating costs for steam drying can be substantial, especially in industrial settings where continuous energy use is required for generating steam. You can reduce long-term expenses by selecting air drying methods when energy efficiency and low operational costs are priorities.

Applications and Suitability

Steam drying is highly suitable for industrial applications requiring rapid moisture removal from textiles, food products, and pharmaceuticals due to its efficiency and ability to maintain product quality. Air drying is ideal for delicate items, such as herbs, handmade crafts, or certain fruits, where low temperatures preserve texture and flavor but requires longer drying times. Your choice depends on the sensitivity of the material and the desired drying speed for optimal results.

Conclusion: Choosing the Right Drying Method

Steam drying preserves nutritional content and texture more effectively than air drying by using controlled heat and moisture removal. Air drying is energy-efficient and suitable for delicate items but may lead to longer drying times and nutrient loss. Selecting the right drying method depends on the product type, desired quality, and energy consumption considerations.

Steam drying vs air drying Infographic

libmatt.com

libmatt.com