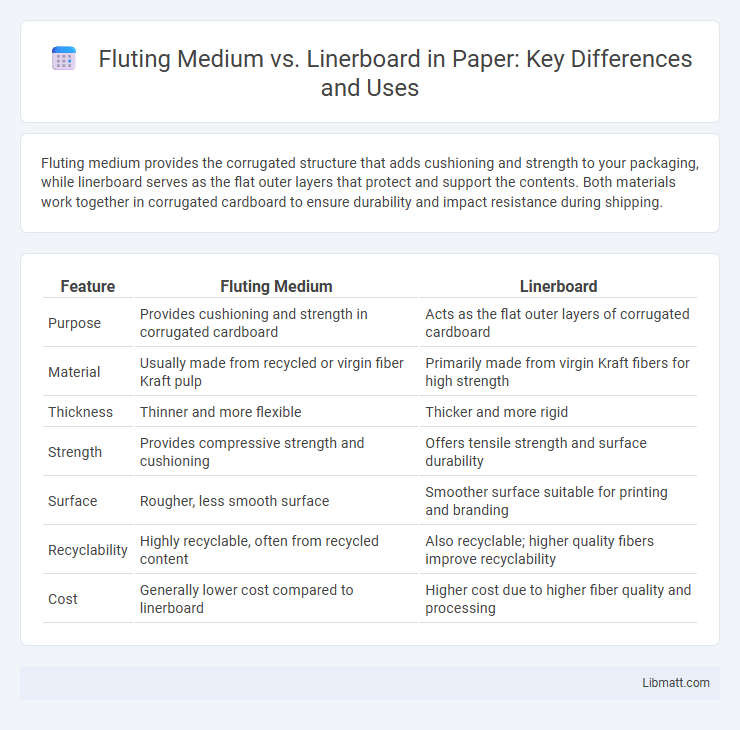

Fluting medium provides the corrugated structure that adds cushioning and strength to your packaging, while linerboard serves as the flat outer layers that protect and support the contents. Both materials work together in corrugated cardboard to ensure durability and impact resistance during shipping.

Table of Comparison

| Feature | Fluting Medium | Linerboard |

|---|---|---|

| Purpose | Provides cushioning and strength in corrugated cardboard | Acts as the flat outer layers of corrugated cardboard |

| Material | Usually made from recycled or virgin fiber Kraft pulp | Primarily made from virgin Kraft fibers for high strength |

| Thickness | Thinner and more flexible | Thicker and more rigid |

| Strength | Provides compressive strength and cushioning | Offers tensile strength and surface durability |

| Surface | Rougher, less smooth surface | Smoother surface suitable for printing and branding |

| Recyclability | Highly recyclable, often from recycled content | Also recyclable; higher quality fibers improve recyclability |

| Cost | Generally lower cost compared to linerboard | Higher cost due to higher fiber quality and processing |

Introduction to Fluting Medium and Linerboard

Fluting medium is a corrugated paperboard component designed with a wavy shape to provide cushioning and rigidity in packaging applications, typically made from recycled fibers to balance strength and flexibility. Linerboard is the flat paperboard that covers the fluted medium, offering a smooth surface for printing and structural support, often composed of kraft pulp for enhanced durability and tear resistance. The combination of fluting medium and linerboard creates a strong, lightweight corrugated cardboard widely used for shipping boxes and protective packaging solutions.

Key Differences Between Fluting Medium and Linerboard

Fluting medium and linerboard differ primarily in function and composition; fluting medium provides the corrugated structure's cushioning and strength, while linerboard forms the flat outer surfaces of corrugated boxes. Fluting medium is typically thinner and more flexible, designed to absorb shocks and protect contents during transport, whereas linerboard is thicker and stiffer, offering durability and printability for branding. Understanding these distinctions helps you choose the right materials to optimize packaging performance and cost efficiency.

Material Composition of Fluting Medium

Fluting medium is primarily made from recycled kraft paper or virgin kraft fibers, designed to provide rigidity and cushioning between linerboard layers in corrugated cardboard. Fluting medium has a lower basis weight and higher moisture content compared to linerboard, optimizing its flexibility and resilience for the corrugated structure. The choice of material composition significantly impacts the fluting medium's bursting strength, crush resistance, and overall board performance.

Material Composition of Linerboard

Linerboard is primarily produced from virgin wood fibers or recycled paper fibers, offering distinct strength and stiffness characteristics vital for corrugated packaging. Fluting medium can be made from lower quality fibers or recycled materials, optimized for fluting structure to provide cushioning and rigidity. The higher cellulose content and longer fibers in linerboard contribute to its superior flat crush resistance and puncture strength compared to fluting medium.

Strength and Durability Comparison

Fluting medium provides superior strength and cushioning due to its fluted structure, which absorbs shocks and protects contents during transport. Linerboard offers a smooth, rigid surface, enhancing stackability and resistance to compression forces in packaging applications. Your choice between fluting medium and linerboard depends on the required balance between durability and structural support for optimal package performance.

Applications of Fluting Medium in Packaging

Fluting medium is primarily used as the corrugated layer in packaging, providing cushioning and structural strength to protect goods during transportation. It serves as the middle layer between linerboards in corrugated cardboard, enhancing impact resistance and shock absorption for fragile or heavy items. Applications of fluting medium include boxes for electronics, food packaging, and industrial containers where durability and protection are critical.

Uses of Linerboard in Corrugated Boxes

Linerboard is a critical component in corrugated boxes, providing the flat outer and inner surfaces that protect the contents and enable printing for branding and information. Compared to fluting medium, which forms the corrugated, wavy layer for cushioning and rigidity, linerboard delivers crucial strength and stacking durability to boxes. Commonly made from kraft pulp, linerboard enhances box performance in packaging, shipping, and storage by resisting compression and moisture.

Cost Implications: Fluting Medium vs Linerboard

Fluting medium typically costs less than linerboard due to its lower density and lighter weight, making it a more economical choice for corrugated board's inner layers. Linerboard, being thicker and stronger, commands higher prices because of its durability and surface quality, essential for packaging outer layers. Cost implications hinge on balancing performance needs with budget constraints, where fluting medium reduces material expenses while linerboard enhances protection and printability.

Environmental Impact and Sustainability

Fluting medium and linerboard differ significantly in environmental impact and sustainability, with fluting medium typically made from recycled fibers, promoting circular economy practices and reducing deforestation. Linerboard, often produced from virgin fibers, has a higher carbon footprint but provides superior strength for packaging durability, potentially reducing waste from damaged goods. Innovations in recycled linerboard and sustainable forestry certifications increasingly enhance the eco-friendliness of both materials in the packaging industry.

Choosing the Right Material for Your Packaging Needs

Fluting medium offers superior cushioning and rigidity, making it ideal for protecting fragile items during shipping, whereas linerboard provides a smooth, printable surface essential for branding and structural integrity. Selecting the right combination of fluting medium and linerboard depends on product weight, fragility, and shipping conditions to ensure optimal durability and presentation. Using high-quality corrugated materials tailored to specific packaging demands enhances protection while minimizing costs and environmental impact.

Fluting medium vs linerboard Infographic

libmatt.com

libmatt.com