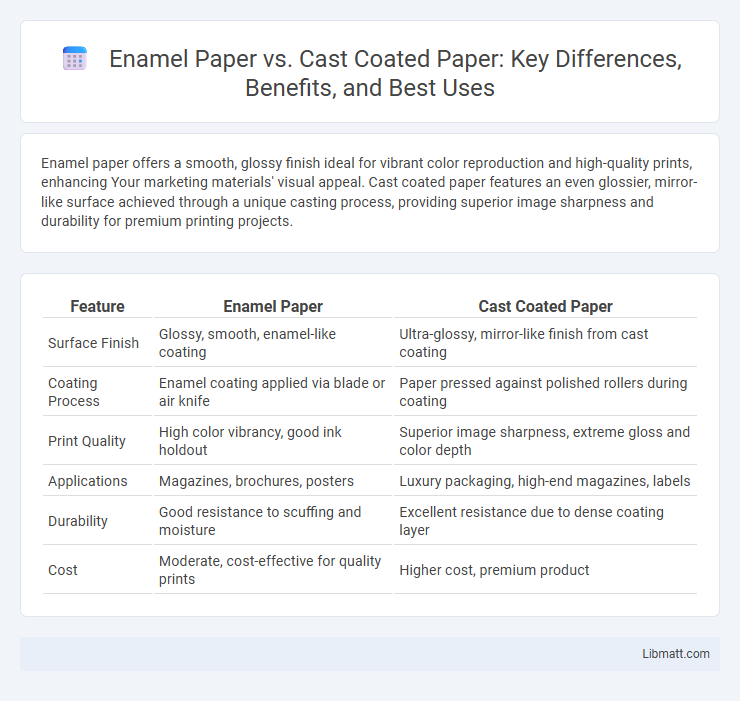

Enamel paper offers a smooth, glossy finish ideal for vibrant color reproduction and high-quality prints, enhancing Your marketing materials' visual appeal. Cast coated paper features an even glossier, mirror-like surface achieved through a unique casting process, providing superior image sharpness and durability for premium printing projects.

Table of Comparison

| Feature | Enamel Paper | Cast Coated Paper |

|---|---|---|

| Surface Finish | Glossy, smooth, enamel-like coating | Ultra-glossy, mirror-like finish from cast coating |

| Coating Process | Enamel coating applied via blade or air knife | Paper pressed against polished rollers during coating |

| Print Quality | High color vibrancy, good ink holdout | Superior image sharpness, extreme gloss and color depth |

| Applications | Magazines, brochures, posters | Luxury packaging, high-end magazines, labels |

| Durability | Good resistance to scuffing and moisture | Excellent resistance due to dense coating layer |

| Cost | Moderate, cost-effective for quality prints | Higher cost, premium product |

Introduction to Enamel Paper and Cast Coated Paper

Enamel paper and cast coated paper are both high-quality coated papers used in premium printing applications, offering smooth surfaces and excellent gloss. Enamel paper features a clay-based coating that enhances ink absorption and color vibrancy, making it ideal for magazines and art books. Cast coated paper undergoes a special finishing process that produces an ultra-glossy, mirror-like surface, perfect for luxury packaging and high-end brochures designed to captivate your audience.

Definition and Composition of Enamel Paper

Enamel paper is a high-quality coated paper featuring a smooth, glossy finish achieved by applying a clay-based enamel coating. Its composition typically includes a base paper layer combined with a mineral-rich enamel coating that enhances brightness, durability, and print clarity. This enamel coating differentiates it from cast coated paper, which relies on a different manufacturing process to produce a mirror-like surface.

What is Cast Coated Paper?

Cast coated paper features a high-gloss, mirror-like finish achieved by pressing the paper against a heated, polished metal plate during production. This process enhances the paper's smoothness, making it ideal for premium printing applications such as magazines and high-end packaging. Compared to enamel paper, cast coated paper offers superior surface gloss and sharp image reproduction due to its unique thermal curing method.

Key Differences in Manufacturing Processes

Enamel paper is produced by applying a smooth, glossy finish through a high-temperature enamel coating process, creating a durable, water-resistant surface ideal for packaging and labels. Cast coated paper involves pressing the paper web against a highly polished metal drum, producing a mirror-like, ultra-smooth finish that enhances print quality and gloss. The key differences lie in enamel paper's chemical coating application and curing techniques versus cast coated paper's mechanical process using heated rollers to achieve surface brilliance.

Surface Finish: Gloss, Smoothness, and Texture

Enamel paper features a high-gloss surface finish with exceptional smoothness, making images and colors appear vibrant and sharp. Cast coated paper offers an ultra-smooth, mirror-like finish achieved through a unique casting process, resulting in superior gloss and a sleek texture ideal for premium printing. Choosing between enamel and cast coated paper will impact your print's visual appeal depending on the desired gloss intensity and tactile experience.

Print Quality and Color Reproduction

Enamel paper offers a smooth, glossy surface that enhances print quality by producing sharp, vibrant images with excellent color saturation and clarity. Cast coated paper provides an ultra-glossy finish achieved through a heat-calendering process, resulting in superior color reproduction with high contrast and a mirror-like sheen. For your printing projects requiring vivid visuals and precise detail, cast coated paper typically delivers more striking and durable results than enamel paper.

Durability and Suitability for Different Applications

Enamel paper features a smooth, glossy finish with moderate durability suitable for high-quality printing like magazines and brochures, offering excellent color reproduction and resistance to smudging. Cast coated paper provides superior durability and a mirror-like gloss, making it ideal for premium packaging, luxury catalogs, and high-end promotional materials where durability and visual impact are critical. Choosing between enamel and cast coated paper depends on your specific application requirements, balancing the need for durability and the desired aesthetic effect.

Cost Comparison between Enamel and Cast Coated Paper

Enamel paper generally incurs higher production costs due to its multi-layer coating process, which enhances gloss and durability compared to cast coated paper. Cast coated paper is more cost-effective, benefiting from a smoother manufacturing technique that requires less intensive coating applications. Businesses often choose cast coated paper for budget-sensitive projects, while enamel paper suits premium prints demanding superior finish and longevity.

Typical Uses in Printing and Packaging Industries

Enamel paper is commonly used in high-quality printing applications such as brochures, magazines, and premium packaging due to its smooth, glossy surface that enhances color vibrancy and detail sharpness. Cast coated paper finds frequent use in luxury packaging, labels, and promotional materials where a mirror-like finish is essential for visual appeal and product differentiation. Both types offer excellent printability, but enamel paper suits offset and digital printing, while cast coated excels in specialized processes requiring superior gloss and smoothness.

Choosing the Right Paper for Your Project

Enamel paper offers a smooth, glossy finish with excellent ink holdout, ideal for vibrant photo prints and high-quality packaging. Cast coated paper features a mirror-like surface achieved through heat and pressure, making it perfect for luxury brochures and premium labels requiring sharp, detailed images. Selecting between enamel and cast coated paper depends on your project's need for gloss intensity, durability, and visual impact to ensure optimal print results.

enamel paper vs cast coated paper Infographic

libmatt.com

libmatt.com