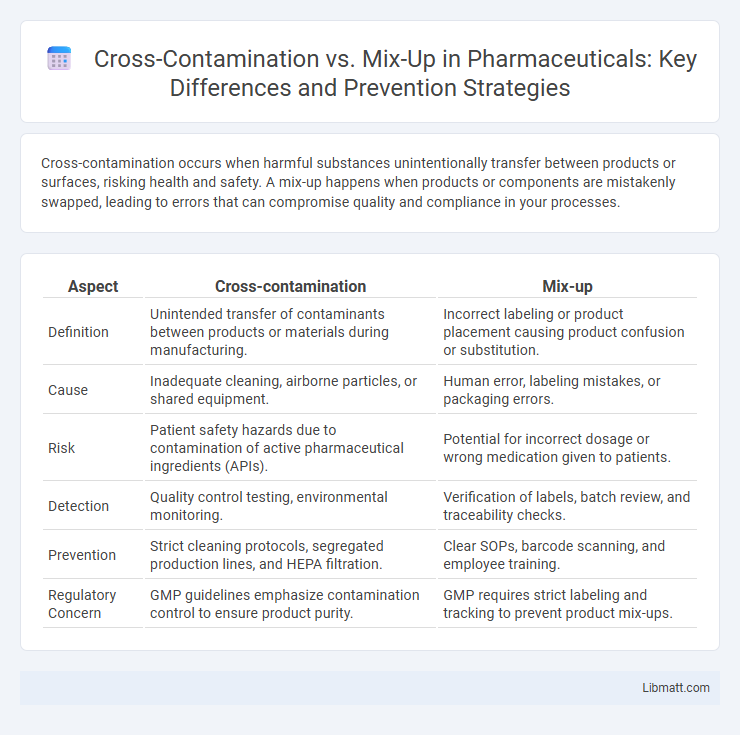

Cross-contamination occurs when harmful substances unintentionally transfer between products or surfaces, risking health and safety. A mix-up happens when products or components are mistakenly swapped, leading to errors that can compromise quality and compliance in your processes.

Table of Comparison

| Aspect | Cross-contamination | Mix-up |

|---|---|---|

| Definition | Unintended transfer of contaminants between products or materials during manufacturing. | Incorrect labeling or product placement causing product confusion or substitution. |

| Cause | Inadequate cleaning, airborne particles, or shared equipment. | Human error, labeling mistakes, or packaging errors. |

| Risk | Patient safety hazards due to contamination of active pharmaceutical ingredients (APIs). | Potential for incorrect dosage or wrong medication given to patients. |

| Detection | Quality control testing, environmental monitoring. | Verification of labels, batch review, and traceability checks. |

| Prevention | Strict cleaning protocols, segregated production lines, and HEPA filtration. | Clear SOPs, barcode scanning, and employee training. |

| Regulatory Concern | GMP guidelines emphasize contamination control to ensure product purity. | GMP requires strict labeling and tracking to prevent product mix-ups. |

Introduction to Cross-Contamination and Mix-up

Cross-contamination occurs when harmful bacteria, allergens, or chemicals unintentionally transfer from one surface, food, or ingredient to another, posing significant risks in food safety and pharmaceutical manufacturing. Mix-up refers to the incorrect identification or substitution of products, batches, or components, leading to errors that compromise quality and safety standards. Both phenomena demand stringent control measures to prevent health hazards and ensure regulatory compliance.

Defining Cross-Contamination

Cross-contamination occurs when harmful bacteria, allergens, or other contaminants transfer from one substance or surface to another, leading to potential health risks. It is a critical concern in food safety, healthcare, and pharmaceutical industries, where strict protocols are necessary to prevent contamination. Understanding cross-contamination helps you implement effective hygiene and handling practices to protect product integrity and consumer safety.

Understanding Mix-up Events

Mix-up events occur when products, components, or materials are incorrectly assigned or labeled, leading to the wrong items being used or delivered. These errors primarily arise from human mistakes during handling, packaging, or documentation processes, resulting in potential quality and safety risks. Identifying and preventing mix-ups is critical in industries like pharmaceuticals and food production to maintain product integrity and consumer trust.

Key Differences Between Cross-Contamination and Mix-up

Cross-contamination involves the unintentional transfer of harmful substances, such as pathogens or allergens, between products or surfaces, leading to contamination that can compromise safety and quality. Mix-up refers to the incorrect labeling, packaging, or identification of products, resulting in the substitution or misplacement of items, which can cause errors in usage or distribution. The key differences lie in cross-contamination being a matter of physical contamination by unwanted agents, while mix-up centers on administrative or procedural errors affecting product identity.

Causes of Cross-Contamination in Manufacturing

Cross-contamination in manufacturing is primarily caused by improper cleaning of equipment, inadequate separation of raw materials, and poor personal hygiene among workers. The transfer of contaminants such as allergens, microbes, or chemicals from one product to another often occurs due to shared utensils, unclean surfaces, or airborne particles. Implementing strict sanitation protocols and designating specific areas for different production stages can significantly reduce the risk of cross-contamination.

Common Sources of Mix-up Errors

Common sources of mix-up errors often stem from mislabeling, improper storage, and inadequate organization of materials or samples. Human errors during handling or processing, such as swapping containers or recording wrong information, contribute significantly to these mistakes. Ensuring strict protocols and clear identification systems is essential to minimize mix-up occurrences.

Risk Factors and Impact on Product Quality

Cross-contamination occurs when unintended substances transfer between products, driven by risk factors such as inadequate cleaning protocols, poor facility design, and human error, leading to compromised product purity and potential health hazards. Mix-up involves the incorrect labeling or handling of products, often caused by insufficient process controls, training gaps, or miscommunication, resulting in product misidentification and regulatory non-compliance. Both risks critically impact product quality by undermining safety, efficacy, and consumer trust, necessitating stringent quality management systems and preventive measures.

Prevention Strategies for Cross-Contamination

Prevention strategies for cross-contamination include implementing strict hygiene protocols, using dedicated equipment for different substances, and ensuring proper training for staff on contamination risks. Segregation of workflows and regular cleaning schedules minimize the chances of contaminants transferring between products or surfaces. Monitoring and validating cleaning procedures are essential to maintain contamination control in manufacturing and healthcare environments.

Best Practices to Avoid Mix-ups

To avoid mix-ups in your processes, implement strict labeling protocols and use barcoding systems for accurate identification. Segregate materials and samples by designated areas to prevent accidental blending, and train staff thoroughly on standard operating procedures. Consistent documentation and regular audits help ensure that your workflow remains error-free and traceable.

Conclusion: Ensuring Product Safety and Compliance

Effective prevention of cross-contamination and mix-up is critical for ensuring product safety and regulatory compliance in pharmaceutical and food industries. Implementing robust quality control systems, such as thorough cleaning protocols and accurate labeling, minimizes risks and maintains product integrity. Consistent staff training and adherence to Good Manufacturing Practices (GMP) further safeguard against contamination and misidentification, securing consumer trust and meeting legal standards.

Cross-contamination vs Mix-up Infographic

libmatt.com

libmatt.com