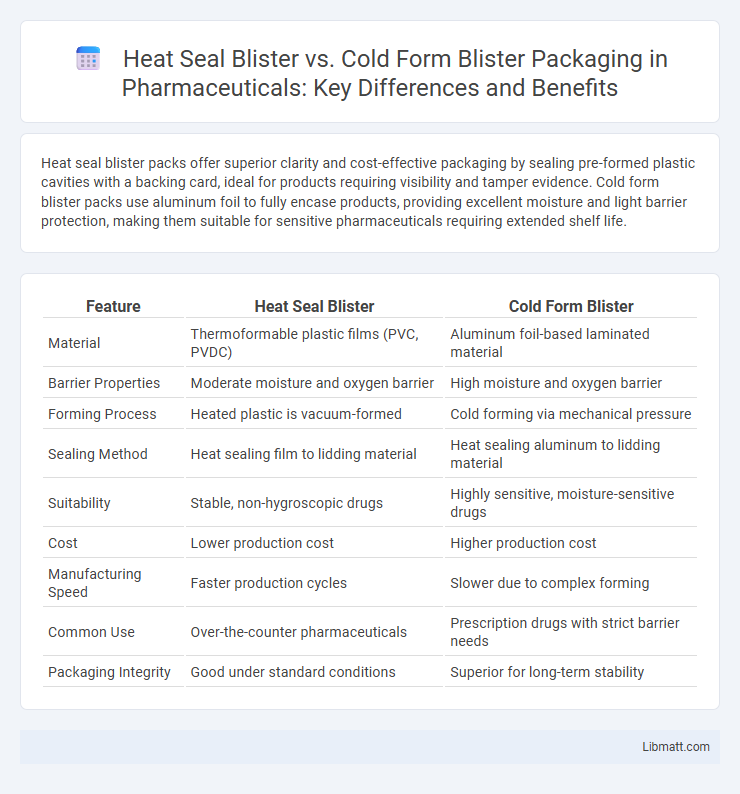

Heat seal blister packs offer superior clarity and cost-effective packaging by sealing pre-formed plastic cavities with a backing card, ideal for products requiring visibility and tamper evidence. Cold form blister packs use aluminum foil to fully encase products, providing excellent moisture and light barrier protection, making them suitable for sensitive pharmaceuticals requiring extended shelf life.

Table of Comparison

| Feature | Heat Seal Blister | Cold Form Blister |

|---|---|---|

| Material | Thermoformable plastic films (PVC, PVDC) | Aluminum foil-based laminated material |

| Barrier Properties | Moderate moisture and oxygen barrier | High moisture and oxygen barrier |

| Forming Process | Heated plastic is vacuum-formed | Cold forming via mechanical pressure |

| Sealing Method | Heat sealing film to lidding material | Heat sealing aluminum to lidding material |

| Suitability | Stable, non-hygroscopic drugs | Highly sensitive, moisture-sensitive drugs |

| Cost | Lower production cost | Higher production cost |

| Manufacturing Speed | Faster production cycles | Slower due to complex forming |

| Common Use | Over-the-counter pharmaceuticals | Prescription drugs with strict barrier needs |

| Packaging Integrity | Good under standard conditions | Superior for long-term stability |

Introduction to Blister Packaging

Blister packaging offers a versatile solution for protecting and displaying products, with Heat Seal Blister and Cold Form Blister being two prominent types. Heat Seal Blister uses a thermoformed plastic cavity sealed with a heat-activated backing, ideal for rigid product protection and clear visibility. Cold Form Blister employs aluminum foil and rigid plastic, providing superior barrier properties ideal for moisture-sensitive pharmaceuticals, ensuring your product remains secure and fresh.

Overview of Heat Seal Blister Packaging

Heat seal blister packaging uses a pre-formed plastic cavity sealed with a lidding material through heat and pressure, creating a secure and tamper-evident package ideal for pharmaceutical tablets or capsules. This packaging method ensures excellent product visibility, moisture resistance, and easy peelability for consumers. Your product benefits from enhanced protection and shelf appeal due to the precise sealing process that maintains product integrity and extends shelf life.

Overview of Cold Form Blister Packaging

Cold Form Blister Packaging utilizes a laminate of aluminum, plastic, and paper to create a highly protective barrier against moisture, oxygen, and light, ensuring superior product stability and extended shelf life. This packaging method is especially suitable for sensitive pharmaceutical products that require enhanced durability and resistance to environmental factors. Your products benefit from the robust sealing and tamper-evident features inherent in cold form blisters, making them ideal for high-value or moisture-sensitive medications.

Materials Used in Heat vs Cold Form Blister Packs

Heat seal blister packs primarily use thermoformable plastic materials such as PVC, PET, or PETG, which enable the packaging to be sealed effectively with a heat application. Cold form blister packs consist of an aluminum-based laminating foil combined with a plastic film, providing superior barrier protection against moisture, oxygen, and light. Understanding the materials used in heat versus cold form blister packs helps you choose the ideal packaging for product stability and shelf life.

Barrier Protection: Heat Seal vs Cold Form

Heat seal blisters provide moderate barrier protection suitable for products with less sensitivity to moisture and oxygen, while cold form blisters offer superior barrier properties due to their aluminum foil-based construction, effectively protecting highly sensitive pharmaceuticals from light, moisture, and oxygen. Your choice between heat seal and cold form blister packaging should depend on the product's stability requirements and shelf life considerations. Cold form blister packs are often preferred for long-term storage, ensuring maximum preservation of product integrity.

Visual Appeal & Product Visibility

Heat seal blister packs provide superior visual appeal and product visibility due to their transparent plastic front, allowing consumers to easily view the product inside with a clean and glossy finish. Cold form blister packs, composed of aluminum foil and plastic, offer less clarity and diminished transparency, resulting in reduced product visibility but enhanced barrier protection. The choice between these two hinges on balancing aesthetic presentation with product preservation needs.

Cost Comparison Between Heat Seal and Cold Form Blisters

Heat seal blisters generally offer a lower initial cost due to simpler manufacturing processes and materials, making them ideal for short to medium production runs. Cold form blisters, made from aluminum foil and plastic laminates, incur higher tooling and material expenses but provide superior barrier protection, enhancing product shelf life. Your choice depends on weighing upfront costs against long-term benefits and product preservation needs.

Suitable Applications for Each Blister Type

Heat seal blister packaging is ideal for products requiring high visibility and easy access, such as consumer electronics, toys, and over-the-counter medications. Cold form blister is better suited for pharmaceuticals needing superior barrier protection against moisture, light, and oxygen, ensuring extended product shelf life. Your choice depends on balancing product protection needs with display and convenience preferences.

Environmental Impact and Sustainability

Heat seal blister packaging uses plastic and paperboard, which can be more easily separated and recycled, promoting better sustainability compared to cold form blisters that rely on aluminum and plastic laminates. Cold form blister packs have a stronger barrier and longer shelf life but are less environmentally friendly due to aluminum's energy-intensive extraction and low recyclability. Selecting heat seal blister packaging supports reduced carbon footprint and waste, aligning better with eco-conscious product strategies.

Choosing the Right Blister Packaging for Your Product

Heat seal blister packaging offers superior clarity and is ideal for products requiring airtight seals and visibility, making it suitable for tablets and consumer electronics. Cold form blister packaging provides excellent barrier protection against moisture, oxygen, and light, perfect for sensitive pharmaceuticals and items needing longer shelf life. Evaluating product sensitivity, shelf life, and presentation requirements helps determine whether heat seal or cold form blister packaging is the best choice.

Heat Seal Blister vs Cold Form Blister Infographic

libmatt.com

libmatt.com