Subvisible particles, typically ranging from 2 to 100 microns, are detected using advanced techniques such as light obscuration or flow microscopy, while visible particles exceed 100 microns and can be identified through visual inspection. Understanding the differences between subvisible and visible particles is crucial for ensuring the safety, efficacy, and quality control of pharmaceutical products in your production process.

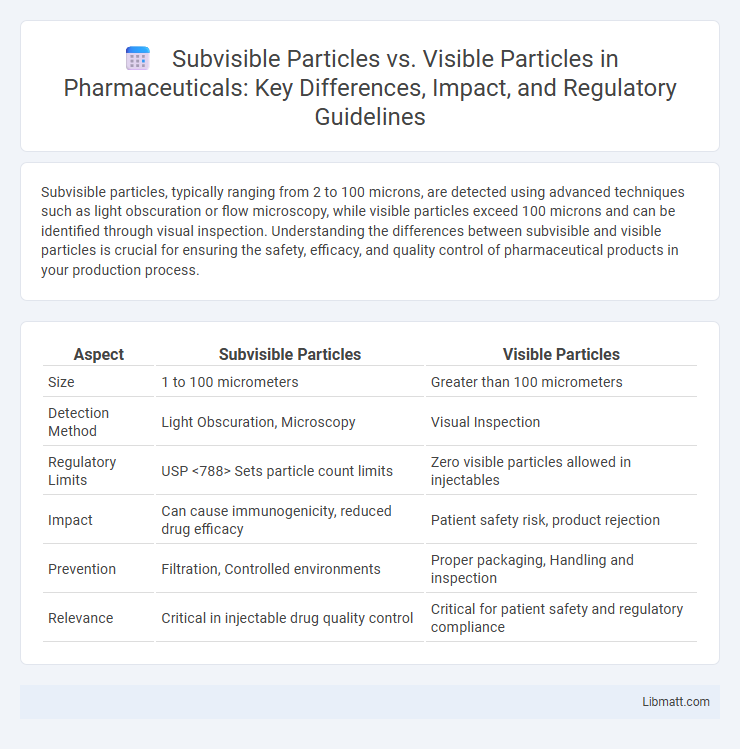

Table of Comparison

| Aspect | Subvisible Particles | Visible Particles |

|---|---|---|

| Size | 1 to 100 micrometers | Greater than 100 micrometers |

| Detection Method | Light Obscuration, Microscopy | Visual Inspection |

| Regulatory Limits | USP <788> Sets particle count limits | Zero visible particles allowed in injectables |

| Impact | Can cause immunogenicity, reduced drug efficacy | Patient safety risk, product rejection |

| Prevention | Filtration, Controlled environments | Proper packaging, Handling and inspection |

| Relevance | Critical in injectable drug quality control | Critical for patient safety and regulatory compliance |

Introduction to Subvisible and Visible Particles

Subvisible particles range from 2 microns up to 100 microns, often undetectable by the naked eye but identifiable through specialized analytical techniques like light obscuration or flow microscopy. Visible particles exceed 100 microns and can be directly observed without instrumentation, posing immediate quality and safety concerns in pharmaceutical products. Differentiating between these particle sizes is crucial for regulatory compliance and ensuring product purity in injectable formulations.

Definitions: What Are Subvisible and Visible Particles?

Subvisible particles are microscopic particles ranging from 0.1 to 100 microns in size that are not detectable by the naked eye but can be identified using specialized analytical instruments such as light obscuration or microscopy. Visible particles are larger impurities typically greater than 100 microns, easily observed without magnification, often indicating contamination or manufacturing defects in pharmaceutical products. Both subvisible and visible particles impact drug safety and efficacy, necessitating stringent regulatory control and monitoring during production.

Sources of Particles in Pharmaceutical Products

Sources of subvisible particles in pharmaceutical products commonly include protein aggregation, silicone oil droplets from syringe lubricants, and particulate matter shed from container closure systems. Visible particles often originate from external contamination, environmental debris, or manufacturing process residues such as fibers and glass shards. Understanding and controlling these sources are critical for ensuring product quality, safety, and regulatory compliance in injectable formulations.

Detection Methods for Subvisible vs Visible Particles

Detection methods for subvisible particles primarily involve techniques such as microflow imaging, light obscuration, and dynamic light scattering, which are designed to identify and quantify particles typically ranging from 0.1 to 100 microns. Visible particle detection relies on manual visual inspection or automated imaging systems capable of detecting larger particles greater than 100 microns. The sensitivity and resolution of detection instruments differ significantly, with subvisible particle methods requiring advanced optical or laser-based technologies to capture smaller contaminants in pharmaceutical formulations.

Regulatory Guidelines and Standards

Regulatory guidelines for subvisible and visible particles differ significantly to ensure pharmaceutical product safety and efficacy. The United States Pharmacopeia (USP) <788> outlines specific limits for visible particles in injections, while USP <787> addresses subvisible particles, setting criteria for quantification by light obscuration or membrane microscopy. International standards such as the European Pharmacopoeia and ICH Q6B harmonize requirements, emphasizing particle size distribution, identification, and acceptable thresholds during product development and quality control.

Impact on Product Quality and Patient Safety

Subvisible particles, typically ranging from 1 to 100 microns, and visible particles, larger than 100 microns, both critically affect product quality and patient safety. Subvisible particles can induce immunogenic responses and compromise drug efficacy by aggregating active pharmaceutical ingredients, while visible particles often indicate contamination or manufacturing defects that may lead to severe adverse reactions. Ensuring your pharmaceutical products meet stringent particle size limits through advanced detection methods is essential to maintain therapeutic effectiveness and protect patient health.

Analytical Techniques for Particle Characterization

Analytical techniques for particle characterization differentiate subvisible particles, typically ranging from 0.1 to 100 microns, from visible particles larger than 100 microns through advanced methods such as micro-flow imaging (MFI), dynamic light scattering (DLS), and nanoparticle tracking analysis (NTA). MFI enables high-resolution imaging and sizing of subvisible particles by analyzing fluid samples under flow, while visual inspection complemented by light microscopy remains standard for visible particles. Regulatory guidelines increasingly emphasize robust analytical characterization of both subvisible and visible particles to ensure biopharmaceutical product safety and quality.

Challenges in Differentiating Particle Types

Differentiating subvisible particles (1-100 microns) from visible particles (>100 microns) poses significant analytical challenges due to overlapping size ranges and variable optical properties. Particle characterization techniques like microscopy, flow imaging, and light obscuration must be optimized to accurately detect and classify these particles without misidentification. Your selection of sensitive detection methods and rigorous validation protocols is crucial to ensure reliable assessment and control of particle contamination in pharmaceuticals or manufacturing processes.

Strategies for Minimizing Particle Contamination

Minimizing particle contamination involves rigorous filtration and cleanroom protocols targeting both subvisible and visible particles to ensure product integrity. Implement high-efficiency filters and conduct regular monitoring using microscopy and light obscuration techniques to detect and quantify particles. Your manufacturing process should integrate validated cleaning procedures and environmental controls to reduce particle generation and maintain compliance with regulatory standards.

Future Trends in Particle Monitoring and Control

Future trends in particle monitoring and control emphasize advanced real-time detection technologies capable of distinguishing subvisible particles (1-100 microns) from visible particles (>100 microns) with greater sensitivity and accuracy. Integration of machine learning algorithms enhances predictive analytics for particle generation sources, improving contamination control in pharmaceutical manufacturing. Continuous inline monitoring systems are expected to become standard, enabling proactive responses to particle contamination and ensuring higher product safety and compliance with evolving regulatory standards.

Subvisible Particles vs Visible Particles Infographic

libmatt.com

libmatt.com