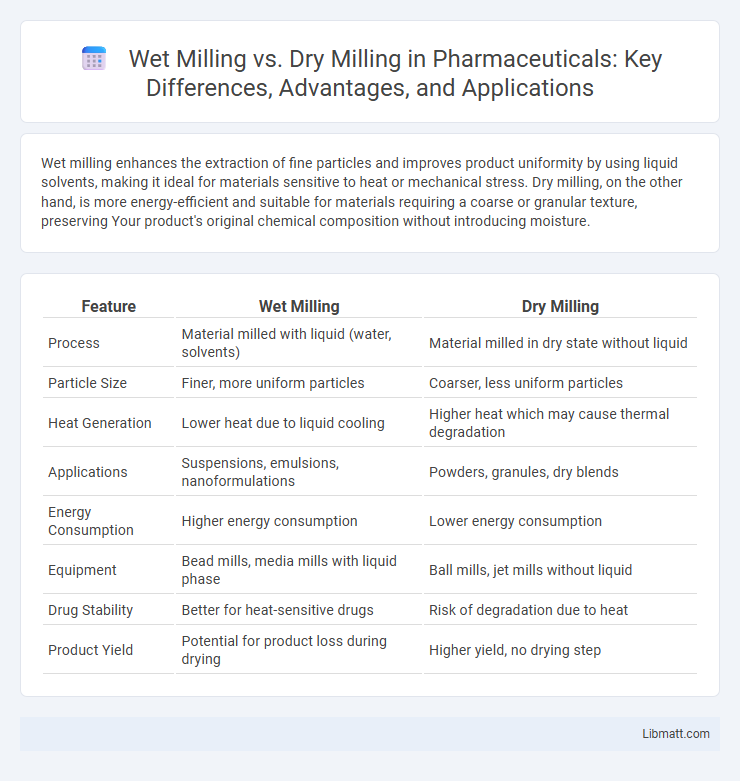

Wet milling enhances the extraction of fine particles and improves product uniformity by using liquid solvents, making it ideal for materials sensitive to heat or mechanical stress. Dry milling, on the other hand, is more energy-efficient and suitable for materials requiring a coarse or granular texture, preserving Your product's original chemical composition without introducing moisture.

Table of Comparison

| Feature | Wet Milling | Dry Milling |

|---|---|---|

| Process | Material milled with liquid (water, solvents) | Material milled in dry state without liquid |

| Particle Size | Finer, more uniform particles | Coarser, less uniform particles |

| Heat Generation | Lower heat due to liquid cooling | Higher heat which may cause thermal degradation |

| Applications | Suspensions, emulsions, nanoformulations | Powders, granules, dry blends |

| Energy Consumption | Higher energy consumption | Lower energy consumption |

| Equipment | Bead mills, media mills with liquid phase | Ball mills, jet mills without liquid |

| Drug Stability | Better for heat-sensitive drugs | Risk of degradation due to heat |

| Product Yield | Potential for product loss during drying | Higher yield, no drying step |

Introduction to Wet Milling and Dry Milling

Wet milling involves grinding materials in the presence of a liquid, typically water, to produce finely dispersed particles and improve suspension stability. Dry milling processes solids without liquid, using mechanical forces to reduce particle size through impact, compression, or shear. The choice between wet and dry milling depends on factors such as material properties, desired particle size, and application requirements in industries like pharmaceuticals, food processing, and mineral extraction.

Key Differences Between Wet and Dry Milling

Wet milling involves processing materials with water or another liquid, which enhances particle size reduction and improves heat dissipation, making it ideal for heat-sensitive substances. Dry milling operates without liquids, relying on mechanical forces to break down materials, which is more energy-efficient but can generate more heat and dust. Key differences include moisture content during processing, particle size control, energy consumption, and the suitability for different material types or end-use applications.

Overview of Wet Milling Process

Wet milling involves grinding materials in a liquid medium, typically water, to produce fine particles and dispersions, commonly used in food processing and pharmaceuticals. The process enhances particle size reduction by suspending solids in the liquid, enabling efficient separation and homogenization. Key advantages include improved solubility, reduced dust generation, and the ability to process heat-sensitive materials.

Overview of Dry Milling Process

Dry milling process involves grinding cereal grains without prior soaking or hydration, resulting in a coarse flour with retained bran and germ components. This method is energy-efficient and preserves nutrient content, making it suitable for producing whole grain flours and feeds. Key equipment includes hammer mills and roller mills, which facilitate size reduction and particle uniformity.

Advantages of Wet Milling

Wet milling offers superior particle size reduction and uniformity compared to dry milling, enhancing the quality and consistency of your final product. The process reduces heat generation, minimizing thermal degradation of sensitive materials, which is crucial for preserving active ingredients in pharmaceuticals or food processing. Wet milling also improves material handling by producing slurries that are easier to transport and blend in subsequent processing steps.

Advantages of Dry Milling

Dry milling offers advantages such as lower energy consumption compared to wet milling, reducing operational costs. It eliminates the need for drying processes, improving production efficiency and minimizing environmental impact. Dry milling also provides better control over particle size and distribution, enhancing product consistency in applications like flour and powdered materials.

Limitations of Wet Milling

Wet milling faces limitations such as higher energy consumption and the need for complex equipment to handle slurry mixtures effectively. It often requires extensive water use, leading to increased operational costs and environmental concerns. Your choice should consider these factors, especially if water availability or waste management is critical in your process.

Limitations of Dry Milling

Dry milling often faces limitations such as increased dust generation, which can pose health and safety risks in manufacturing environments. It typically results in less uniform particle sizes and lower product quality compared to wet milling, impacting the efficiency of material processing. If your operation demands precision and minimal contamination, wet milling may offer better control and consistency.

Applications in Various Industries

Wet milling is widely used in the pharmaceutical, food, and chemical industries for producing fine suspensions, emulsions, and powders due to its ability to process heat-sensitive materials and achieve uniform particle size distribution. Dry milling finds extensive applications in mining, construction, and ceramics, where it efficiently reduces hard, brittle materials to fine powders without the need for liquid media. Your choice between wet and dry milling depends on the material characteristics and desired end-product properties in specific industrial applications.

Choosing the Right Milling Method

Choosing the right milling method depends on the material properties and desired end-product characteristics, with wet milling preferred for heat-sensitive or sticky substances due to its cooling effect and improved particle size reduction. Dry milling suits materials stable at higher temperatures and provides easier handling without the need for drying post-process. Evaluating factors such as moisture content, equipment cost, and energy consumption helps optimize efficiency and product quality between wet and dry milling.

Wet Milling vs Dry Milling Infographic

libmatt.com

libmatt.com