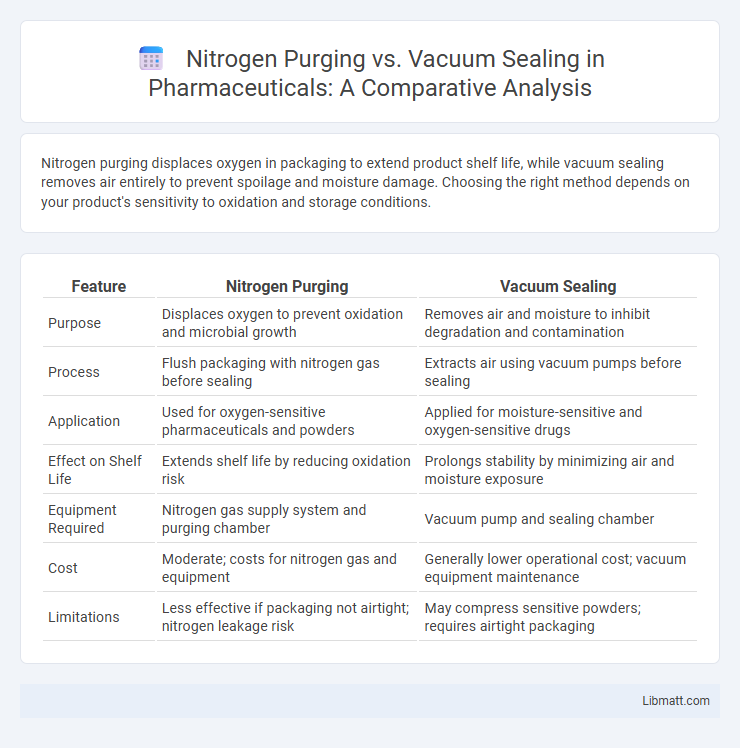

Nitrogen purging displaces oxygen in packaging to extend product shelf life, while vacuum sealing removes air entirely to prevent spoilage and moisture damage. Choosing the right method depends on your product's sensitivity to oxidation and storage conditions.

Table of Comparison

| Feature | Nitrogen Purging | Vacuum Sealing |

|---|---|---|

| Purpose | Displaces oxygen to prevent oxidation and microbial growth | Removes air and moisture to inhibit degradation and contamination |

| Process | Flush packaging with nitrogen gas before sealing | Extracts air using vacuum pumps before sealing |

| Application | Used for oxygen-sensitive pharmaceuticals and powders | Applied for moisture-sensitive and oxygen-sensitive drugs |

| Effect on Shelf Life | Extends shelf life by reducing oxidation risk | Prolongs stability by minimizing air and moisture exposure |

| Equipment Required | Nitrogen gas supply system and purging chamber | Vacuum pump and sealing chamber |

| Cost | Moderate; costs for nitrogen gas and equipment | Generally lower operational cost; vacuum equipment maintenance |

| Limitations | Less effective if packaging not airtight; nitrogen leakage risk | May compress sensitive powders; requires airtight packaging |

Introduction to Nitrogen Purging and Vacuum Sealing

Nitrogen purging replaces oxygen in packaging with nitrogen gas to prevent oxidation and extend shelf life, commonly used in food and electronics industries. Vacuum sealing removes air from packaging to create a tight seal, reducing moisture and microbial growth that spoil products. Your choice between these methods depends on the product's sensitivity to oxygen and moisture control requirements.

What is Nitrogen Purging?

Nitrogen purging involves replacing oxygen and other gases in a container or system with nitrogen to prevent oxidation, moisture, and contamination. This inert gas creates an oxygen-free environment that enhances the shelf life and quality of sensitive products or materials. If you want to protect your items from degradation and corrosion, nitrogen purging is an effective solution compared to traditional vacuum sealing methods.

What is Vacuum Sealing?

Vacuum sealing is a packaging method that removes air from the container to create a low-pressure environment, effectively extending the shelf life of products by reducing oxidation and inhibiting bacterial growth. This technique is widely used in food preservation, electronics packaging, and pharmaceuticals to maintain freshness and prevent contamination. Your products benefit from vacuum sealing through improved storage stability and protection from moisture and environmental factors.

Key Differences Between Nitrogen Purging and Vacuum Sealing

Nitrogen purging replaces oxygen with inert nitrogen gas to prevent oxidation and extend product shelf life, while vacuum sealing removes air entirely to create a low-pressure environment that inhibits microbial growth. Nitrogen purging is ideal for sensitive products like electronics and food requiring oxygen exclusion without moisture removal, whereas vacuum sealing is effective for dry goods needing airtight preservation. The primary difference lies in nitrogen purging maintaining slight internal pressure and gas composition control, contrasting with vacuum sealing's emphasis on air evacuation and pressure reduction.

Advantages of Nitrogen Purging

Nitrogen purging offers superior protection against oxidation and moisture by displacing oxygen with inert nitrogen gas, extending the shelf life of sensitive products. This method prevents microbial growth and preserves quality without physically altering the package's structure, unlike vacuum sealing. You benefit from reduced spoilage and enhanced freshness, making nitrogen purging ideal for pharmaceuticals, electronics, and perishable food items.

Benefits of Vacuum Sealing

Vacuum sealing effectively removes air and moisture from packaging, significantly extending the shelf life of food and sensitive products by preventing oxidation and microbial growth. This method preserves the texture, flavor, and nutritional quality while reducing freezer burn compared to nitrogen purging. Your items remain fresher longer, making vacuum sealing an ideal choice for both storage and transportation.

Applications of Nitrogen Purging

Nitrogen purging is widely used in industries such as food packaging, pharmaceuticals, and electronics to prevent oxidation and moisture contamination by replacing oxygen within sealed environments. This technique extends shelf life, preserves product quality, and ensures safety during storage and transportation. Your products benefit from enhanced freshness and reduced spoilage when nitrogen purging is applied effectively.

Common Uses of Vacuum Sealing

Vacuum sealing is widely used in food preservation to extend shelf life by removing air and inhibiting bacterial growth, making it ideal for storing meats, vegetables, and leftovers. It also protects sensitive electronics and medical devices from moisture and dust, ensuring product integrity during storage and shipping. You can rely on vacuum sealing for efficient packaging solutions in both household and industrial applications.

Choosing the Right Method for Your Needs

Selecting between nitrogen purging and vacuum sealing depends on the specific requirements for product preservation and shelf life extension. Nitrogen purging replaces oxygen with inert nitrogen gas, ideal for preventing oxidation in sensitive foods and electronics packaging. Vacuum sealing removes air entirely, creating an oxygen-free environment suited for moisture-sensitive goods and long-term storage.

Conclusion: Nitrogen Purging vs Vacuum Sealing

Nitrogen purging effectively removes oxygen to prevent oxidation and moisture, preserving product freshness and extending shelf life in sensitive applications such as food and pharmaceuticals. Vacuum sealing eliminates air by creating a low-pressure environment, reducing microbial growth and preventing freezer burn, ideal for everyday food storage and packaging. Your choice depends on the specific preservation needs, with nitrogen purging favored for highly oxygen-sensitive products and vacuum sealing suited for general moisture and air removal.

Nitrogen Purging vs Vacuum Sealing Infographic

libmatt.com

libmatt.com