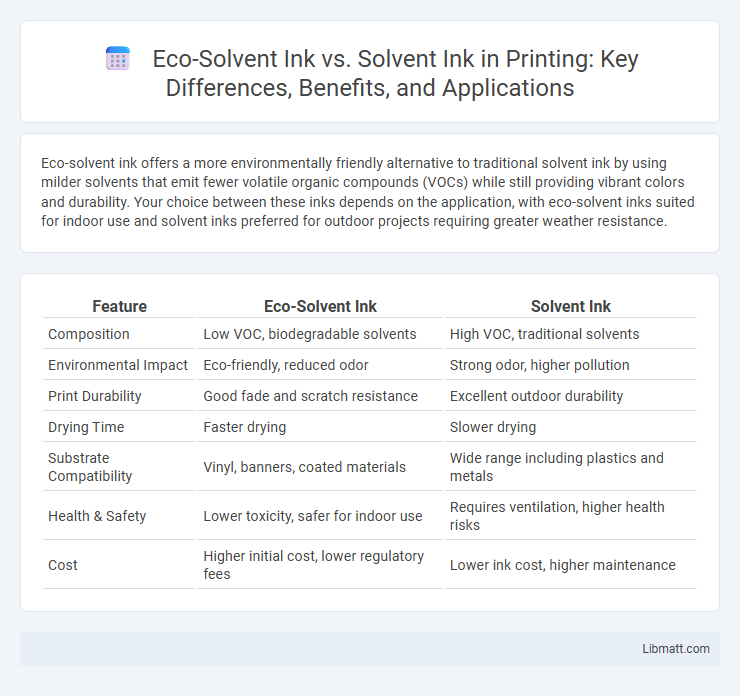

Eco-solvent ink offers a more environmentally friendly alternative to traditional solvent ink by using milder solvents that emit fewer volatile organic compounds (VOCs) while still providing vibrant colors and durability. Your choice between these inks depends on the application, with eco-solvent inks suited for indoor use and solvent inks preferred for outdoor projects requiring greater weather resistance.

Table of Comparison

| Feature | Eco-Solvent Ink | Solvent Ink |

|---|---|---|

| Composition | Low VOC, biodegradable solvents | High VOC, traditional solvents |

| Environmental Impact | Eco-friendly, reduced odor | Strong odor, higher pollution |

| Print Durability | Good fade and scratch resistance | Excellent outdoor durability |

| Drying Time | Faster drying | Slower drying |

| Substrate Compatibility | Vinyl, banners, coated materials | Wide range including plastics and metals |

| Health & Safety | Lower toxicity, safer for indoor use | Requires ventilation, higher health risks |

| Cost | Higher initial cost, lower regulatory fees | Lower ink cost, higher maintenance |

Introduction to Eco-Solvent Ink and Solvent Ink

Eco-solvent ink is a type of printing ink formulated with mild solvents that enable high-quality prints on vinyl, banner, and adhesive media while producing fewer harmful emissions compared to traditional solvent inks. Solvent ink, composed of stronger chemical solvents, is known for its durability and water resistance, making it ideal for outdoor signage and long-lasting applications. Both inks serve distinct purposes in large-format printing, with eco-solvent prioritizing environmental safety and solvent ink offering robust performance in harsh conditions.

Composition and Chemical Properties

Eco-solvent inks are primarily composed of biodegradable solvents such as methyl acetate and ethyl lactate, which reduce harmful volatile organic compounds (VOCs) emissions and exhibit lower toxicity compared to traditional solvent inks. Solvent inks contain stronger chemical solvents like toluene and xylene, making them highly durable and water-resistant but also more hazardous to health and the environment due to higher VOC content. Chemical properties of eco-solvent inks enable safer indoor use and easier cleanup while solvent inks require specialized handling and ventilation systems to mitigate their environmental impact.

Printing Applications and Uses

Eco-solvent ink is widely used in indoor and outdoor graphics, including vehicle wraps, banners, and wall decals due to its low odor, reduced environmental impact, and compatibility with flexible vinyl and coated substrates. Solvent ink excels in durable outdoor signage, billboards, and industrial labeling thanks to its superior UV resistance, water resistance, and adhesion on non-porous surfaces. Both inks serve high-quality printing needs, but eco-solvent ink offers safer handling and easier cleanup for settings prioritizing environmental safety.

Environmental Impact and Safety

Eco-solvent ink produces fewer volatile organic compounds (VOCs) and emits lower levels of harmful chemicals compared to traditional solvent ink, making it a safer option for indoor and poorly ventilated environments. The biodegradable components in eco-solvent inks reduce environmental pollution and facilitate easier waste disposal, whereas conventional solvent inks contribute significantly to air and soil contamination due to toxic solvents. Workers handling eco-solvent inks face decreased health risks such as respiratory issues and skin irritation, highlighting its advantage in occupational safety over solvent inks.

Print Quality and Color Vibrancy

Eco-solvent ink delivers high print quality with smooth gradients and sharp details, making it ideal for indoor signage and vehicle graphics. Solvent ink offers superior durability and color vibrancy, particularly on outdoor applications where UV resistance and weatherproofing are critical. Your choice depends on whether you prioritize eco-friendliness and flexibility or maximum vibrancy and outdoor resilience.

Durability and Weather Resistance

Eco-solvent ink offers moderate durability and weather resistance, making it suitable for indoor and short-term outdoor applications with exposure to light moisture and mild weather conditions. Solvent ink provides superior durability and excellent weather resistance, performing well under harsh outdoor environments with strong UV exposure and heavy rain, ensuring vibrant colors and long-lasting prints. For long-term outdoor signage, solvent ink remains the preferred choice due to its robust adhesion and fade-resistant properties.

Printer Compatibility and Maintenance

Eco-solvent ink offers broader printer compatibility, working well with many desktop and wide-format printers designed for lower VOC emissions, while traditional solvent ink requires printers specifically built to handle its strong chemical properties. Maintenance for eco-solvent ink systems is generally simpler due to less aggressive solvents, reducing the risk of nozzle clogging and extending printhead life. Choosing eco-solvent ink can lower your printer upkeep costs and minimize downtime compared to solvent ink, which demands more frequent and intensive cleaning procedures.

Cost Comparison and Affordability

Eco-solvent ink generally offers a more affordable option for printing due to lower raw material and disposal costs compared to traditional solvent ink, which tends to be pricier because of its strong chemical components and higher VOC content. The reduced environmental impact of eco-solvent ink often translates into savings on ventilation and safety equipment in production environments. While solvent ink may deliver more durability in outdoor applications, eco-solvent ink provides a cost-effective balance for businesses prioritizing both budget and eco-friendliness.

Pros and Cons of Eco-Solvent and Solvent Inks

Eco-solvent inks offer lower VOC emissions and reduced odor, making them environmentally friendly and suitable for indoor use, but they have slower drying times and lower chemical resistance compared to solvent inks. Solvent inks provide superior durability, water resistance, and vibrant colors on outdoor applications, yet they emit stronger odors and require better ventilation due to higher levels of harmful solvents. Choosing between eco-solvent and solvent inks depends on the printing environment, substrate compatibility, and regulatory considerations related to VOC emissions.

Which Ink is Right for Your Printing Needs?

Eco-solvent ink offers a more environmentally friendly option with lower VOC emissions and is ideal for indoor graphics, providing vibrant colors and durability on coated materials. Solvent ink, known for its superior adhesion and resistance to harsh outdoor conditions, suits long-term outdoor signage requiring high longevity and weather resistance. By evaluating your specific printing needs, such as substrate compatibility and environmental impact, you can choose the ink that best balances quality and sustainability for your projects.

Eco-solvent ink vs solvent ink Infographic

libmatt.com

libmatt.com