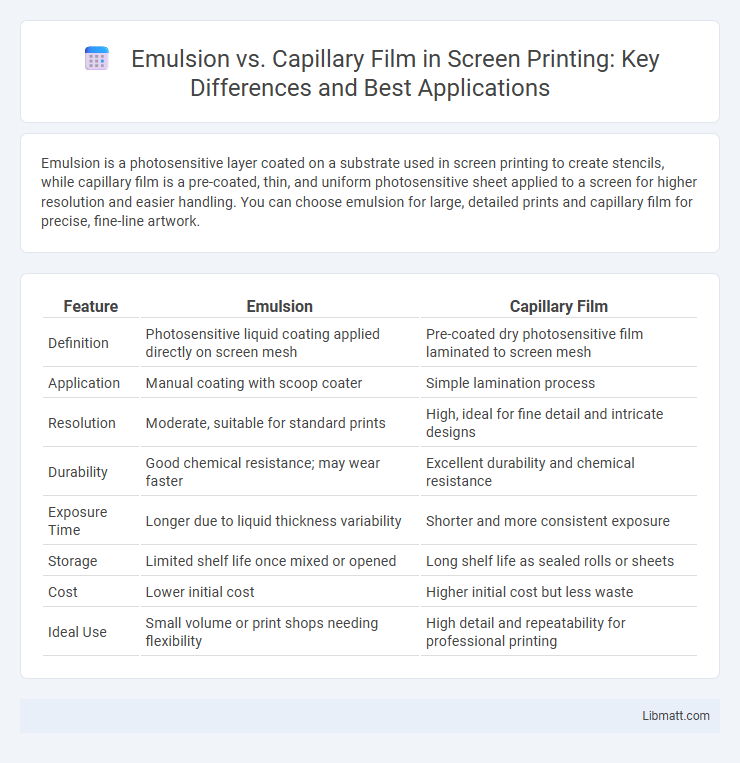

Emulsion is a photosensitive layer coated on a substrate used in screen printing to create stencils, while capillary film is a pre-coated, thin, and uniform photosensitive sheet applied to a screen for higher resolution and easier handling. You can choose emulsion for large, detailed prints and capillary film for precise, fine-line artwork.

Table of Comparison

| Feature | Emulsion | Capillary Film |

|---|---|---|

| Definition | Photosensitive liquid coating applied directly on screen mesh | Pre-coated dry photosensitive film laminated to screen mesh |

| Application | Manual coating with scoop coater | Simple lamination process |

| Resolution | Moderate, suitable for standard prints | High, ideal for fine detail and intricate designs |

| Durability | Good chemical resistance; may wear faster | Excellent durability and chemical resistance |

| Exposure Time | Longer due to liquid thickness variability | Shorter and more consistent exposure |

| Storage | Limited shelf life once mixed or opened | Long shelf life as sealed rolls or sheets |

| Cost | Lower initial cost | Higher initial cost but less waste |

| Ideal Use | Small volume or print shops needing flexibility | High detail and repeatability for professional printing |

Introduction to Emulsion and Capillary Film

Emulsion coating consists of a light-sensitive chemical layer applied on a substrate, enabling fine image reproduction in screen printing. Capillary film is a dry, pre-coated emulsion sheet attached to a polyester base, designed for precise stencil creation with consistent thickness. Both emulsions and capillary films are essential for high-resolution printing, offering varied application methods and durability for different production needs.

What is Emulsion?

Emulsion is a light-sensitive layer composed of silver halide crystals suspended in gelatin, used primarily in photographic films and printing processes. It reacts to light exposure, creating a latent image that can be developed into a visible picture or pattern. Your choice of emulsion type affects resolution and contrast in applications like screen printing or traditional photography.

What is Capillary Film?

Capillary film is a thin, uniform layer of photosensitive emulsion applied to a polyester base, primarily used in screen printing for producing high-resolution stencils. This film offers consistent thickness and superior imaging quality compared to traditional liquid emulsions, enabling finer detail reproduction and enhanced durability. Its precise formulation facilitates easy exposure, development, and cleaning, making it ideal for intricate graphic designs and professional textile printing applications.

Application Techniques Compared

Emulsion and capillary film differ significantly in application techniques; emulsion is typically poured or spread directly onto the screen and dried in a dark, dust-free environment, requiring careful control of temperature and humidity for optimal coating quality. Capillary film, on the other hand, comes as a pre-coated photosensitive film that is carefully adhered to the screen and squeegeed flat, ensuring uniform thickness and eliminating the need for coating equipment. Your choice depends on workflow efficiency and precision, as capillary films offer faster setup and consistent thickness, while emulsion provides flexibility in coating thickness adjustments.

Image Quality and Detail Resolution

Emulsions provide high sensitivity and finer grain structure, resulting in superior image sharpness and detailed resolution for photographic prints. Capillary films offer uniform thickness, which enhances image contrast but may produce slightly less fine detail compared to traditional emulsions. The choice depends on the balance between desired image clarity and contrast for specific applications like screen printing or photographic reproduction.

Drying and Handling Times

Emulsion drying times on capillary films typically range from 24 to 48 hours depending on ambient humidity and temperature, while handling times for capillary films are much shorter, often within minutes to an hour due to their pre-coated nature. Capillary films require minimal drying before exposure, facilitating faster workflow in screen printing processes compared to traditional emulsion coatings that necessitate thorough drying to avoid defects. Proper handling of emulsions demands careful environmental control to prevent premature degradation, whereas capillary films offer enhanced durability and convenience, reducing setup time and minimizing operator error.

Consistency and Thickness Control

Emulsion films offer superior consistency due to their liquid state before drying, allowing for precise application thickness and uniformity in screen printing. Capillary films come pre-coated with a controlled thickness layer of emulsion, ensuring reproducible thickness but less flexibility in adjusting coating thickness on-site. Both methods provide reliable thickness control, with emulsion films excelling in adaptability and capillary films ensuring standardized consistency.

Cost Analysis: Emulsion vs Capillary Film

Emulsion typically offers a lower initial cost compared to capillary film, making it a budget-friendly choice for large-volume screen printing projects. Capillary film, while more expensive upfront due to its precision and uniform thickness, reduces waste and rework costs by providing consistent stencil quality and faster setup times. Your decision should weigh the lower material cost of emulsion against the potential long-term savings and improved print quality offered by capillary film.

Best Use Cases for Each Method

Emulsion is ideal for screen printing when fine detail and high-resolution images are required, offering exceptional stencil definition on various mesh counts. Capillary film works best in high-volume production environments due to its ease of application and consistent thickness, making it suitable for printing on flat, smooth surfaces. Choosing emulsion suits complex designs and small runs, while capillary film optimizes efficiency and repeatability in large-scale jobs.

Final Verdict: Choosing the Right Stencil Method

Emulsion offers versatility and durability ideal for varied screen printing projects, providing a reliable stencil with strong adhesion and fine detail reproduction. Capillary film ensures higher precision and faster exposure times, excelling in consistent line work and complex designs, making it a top choice for commercial printing. Selecting the right stencil method depends on project complexity, production speed, and longevity requirements, with emulsion favoring versatility and capillary film favoring precision and efficiency.

Emulsion vs capillary film Infographic

libmatt.com

libmatt.com