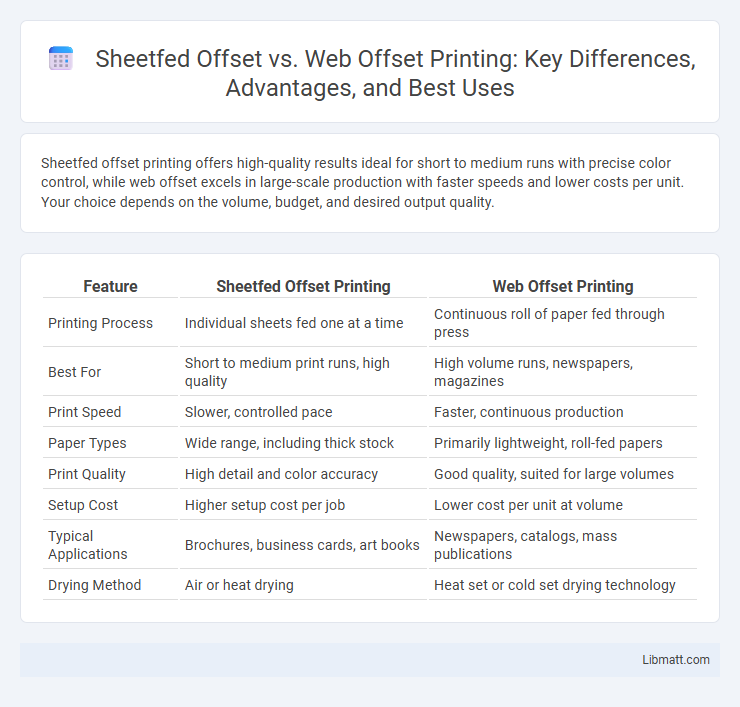

Sheetfed offset printing offers high-quality results ideal for short to medium runs with precise color control, while web offset excels in large-scale production with faster speeds and lower costs per unit. Your choice depends on the volume, budget, and desired output quality.

Table of Comparison

| Feature | Sheetfed Offset Printing | Web Offset Printing |

|---|---|---|

| Printing Process | Individual sheets fed one at a time | Continuous roll of paper fed through press |

| Best For | Short to medium print runs, high quality | High volume runs, newspapers, magazines |

| Print Speed | Slower, controlled pace | Faster, continuous production |

| Paper Types | Wide range, including thick stock | Primarily lightweight, roll-fed papers |

| Print Quality | High detail and color accuracy | Good quality, suited for large volumes |

| Setup Cost | Higher setup cost per job | Lower cost per unit at volume |

| Typical Applications | Brochures, business cards, art books | Newspapers, catalogs, mass publications |

| Drying Method | Air or heat drying | Heat set or cold set drying technology |

Introduction to Sheetfed and Web Offset Printing

Sheetfed offset printing utilizes individual sheets of paper fed through the press, offering high-quality, precise color reproduction suited for smaller print runs and detailed images. Web offset printing continuously feeds a large roll of paper, enabling rapid production and cost efficiency for high-volume jobs like newspapers and magazines. Both methods rely on the offset technique of transferring ink from a plate to a rubber blanket and then onto paper, optimizing print clarity and detail.

Key Differences Between Sheetfed and Web Offset

Sheetfed offset presses print on individual sheets of paper, offering superior image quality and flexibility for short to medium runs, making them ideal for brochures, business cards, and smaller print jobs. Web offset presses utilize continuous rolls of paper, enabling high-speed production and cost-efficiency for large volume runs such as newspapers, magazines, and catalogs. Understanding these key differences helps you select the right printing method based on your project's scale, budget, and quality requirements.

How Sheetfed Offset Printing Works

Sheetfed offset printing operates by feeding individual sheets of paper through a printing press where each sheet passes through a series of inked plates transferring the image onto a rubber blanket and then onto the paper. This method allows precise color registration and sharp image quality, making it ideal for high-detail prints such as brochures, catalogs, and art books. The process excels in producing smaller print runs with high variability in paper types and weights, offering versatility unmatched by web offset printing.

How Web Offset Printing Works

Web offset printing operates by continuously feeding a large roll of paper through the press, allowing for high-speed and high-volume production. The inked image is transferred from a metal plate to a rubber blanket, then directly onto the moving paper, ensuring consistent print quality and efficient use of materials. This method is ideal for printing newspapers, magazines, and catalogs due to its speed and cost-effectiveness for long runs.

Print Quality Comparison: Sheetfed vs Web Offset

Sheetfed offset printing offers superior print quality with sharper images and finer detail due to higher resolution capabilities and precise ink control, making it ideal for high-end commercial projects. Web offset printing, while faster and more cost-effective for large runs, generally produces slightly lower resolution prints that can exhibit minor banding or color inconsistencies. The choice between sheetfed and web offset impacts the final print quality significantly, with sheetfed favored for premium, short-run applications and web offset suited for high-volume, cost-sensitive jobs.

Cost Considerations: Sheetfed vs Web Offset

Sheetfed offset printing typically incurs higher per-unit costs due to its slower setup times and smaller print runs, making it ideal for short to medium quantities with high-quality output. Web offset printing offers lower per-unit costs on large volume jobs because of continuous roll-fed paper and faster production speeds, reducing overall expenses for extensive print runs. Understanding your project's scale and budget helps determine if sheetfed's precision or web offset's cost efficiency better suits your requirements.

Production Speed and Volume Efficiency

Sheetfed offset printing offers moderate production speeds, typically handling shorter runs of up to 10,000 sheets efficiently, making it ideal for detailed, high-quality prints and various paper sizes. Web offset printing excels in high-volume production, capable of printing thousands of impressions per hour with continuous rolls of paper, resulting in faster turnaround times for large-scale jobs like newspapers and magazines. The continuous feed mechanism of web offset reduces downtime, significantly enhancing volume efficiency compared to the stop-and-start operation of sheetfed offset presses.

Suitable Applications for Each Printing Method

Sheetfed offset excels in high-quality, short to medium print runs such as brochures, business cards, and magazines where precise color control and sharp image quality are essential. Web offset is ideal for large-scale, fast production of newspapers, catalogs, and direct mail, benefiting from continuous roll-fed paper and higher speed output. Your choice depends on the volume and quality requirements, with sheetfed suited for detailed visuals and web offset for cost-effective mass distribution.

Environmental Impact and Waste Management

Sheetfed offset printing generates less waste due to precise sheet handling and smaller print runs, reducing paper usage and energy consumption compared to web offset presses. Web offset printing, typically used for high-volume jobs, produces significant paper waste from continuous rolls and requires more complex waste management systems. Your choice between these methods can influence the environmental footprint of your printing project, with sheetfed offset offering more sustainable options for smaller batches.

Choosing the Right Printing Method for Your Project

Sheetfed offset printing offers high-quality, precise color reproduction ideal for shorter runs and projects requiring detailed graphics, while web offset printing excels in high-volume jobs with faster turnaround times and cost efficiency per unit. Your choice depends on factors like print quantity, budget, and desired finish--sheetfed is better for shorter, premium jobs, and web offset suits large-scale commercial printing. Evaluating these key differences ensures your project achieves optimal quality and cost-effectiveness.

Sheetfed Offset vs Web Offset Infographic

libmatt.com

libmatt.com