Spot UV adds a glossy, raised texture to specific areas of your print, creating a striking contrast and highlighting particular design elements, while silk varnish offers a smooth, matte finish that enhances durability and provides a subtle, elegant sheen over the entire surface. Spot UV is ideal for emphasizing logos or text, whereas silk varnish gives your print a refined, soft touch without the shine.

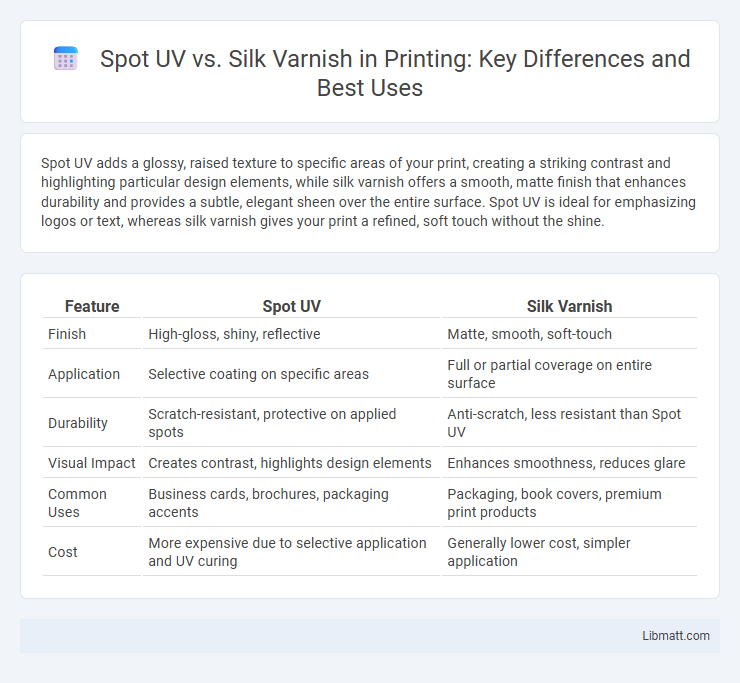

Table of Comparison

| Feature | Spot UV | Silk Varnish |

|---|---|---|

| Finish | High-gloss, shiny, reflective | Matte, smooth, soft-touch |

| Application | Selective coating on specific areas | Full or partial coverage on entire surface |

| Durability | Scratch-resistant, protective on applied spots | Anti-scratch, less resistant than Spot UV |

| Visual Impact | Creates contrast, highlights design elements | Enhances smoothness, reduces glare |

| Common Uses | Business cards, brochures, packaging accents | Packaging, book covers, premium print products |

| Cost | More expensive due to selective application and UV curing | Generally lower cost, simpler application |

Introduction to Spot UV and Silk Varnish

Spot UV is a raised, glossy coating applied selectively to specific areas of a printed piece, enhancing visual contrast and tactile appeal. Silk varnish provides a smooth, matte finish with a subtle sheen, improving durability while maintaining a soft texture. Both finishes serve distinct aesthetic and protective purposes in premium print materials.

What is Spot UV?

Spot UV is a high-gloss coating applied selectively to specific areas of a printed piece, creating a striking contrast against matte or silk varnish finishes. This technique enhances visual appeal and highlights design elements by adding depth and shine, making logos, images, or text pop. Your marketing materials benefit from Spot UV's ability to attract attention and convey sophistication through tactile and visual contrast.

What is Silk Varnish?

Silk varnish is a smooth, matte coating applied to printed materials to enhance durability while providing a subtle, non-glossy finish that resists fingerprints and scuffs. It offers moderate protection and improves color richness without the high shine of traditional gloss varnish. This varnish is ideal for professional prints that require a refined appearance with tactile softness.

Visual Effects: Spot UV vs Silk Varnish

Spot UV creates a high-gloss, raised finish that enhances specific areas with a striking contrast against matte or uncoated surfaces, offering dramatic visual and tactile effects. Silk varnish provides a soft, smooth, and matte sheen that reduces glare while delivering a subtle, elegant appearance, ideal for uniform coverage. The choice between Spot UV and silk varnish depends on the desired emphasis: bold highlights with tactile dimension versus understated, refined protection.

Durability and Protection Comparison

Spot UV offers a high-gloss, raised finish that provides superior durability and resistance to scratches and moisture, making it ideal for protecting key design elements. Silk varnish features a smooth, matte finish with moderate protection against wear and tear, preserving your print's subtle elegance while enhancing surface resilience. Choosing between the two depends on whether you prioritize enhanced protection with a glossy highlight or a softer, more tactile finish with reliable durability.

Application Methods and Processes

Spot UV is applied using a screen-printing process where a glossy, ultraviolet-curable liquid is precisely coated onto specific areas of the printed surface and cured instantly with UV light, creating a high-gloss, raised effect. Silk varnish is typically sprayed or rolled onto the entire surface, forming a smooth, matte finish with a soft sheen that reduces glare and provides subtle texture. Spot UV requires precise alignment with the print design for targeted gloss effects, while silk varnish offers uniform coverage suitable for protecting the overall print.

Cost Differences: Spot UV vs Silk Varnish

Spot UV coating tends to be more expensive than silk varnish due to the specialized equipment and precise application required for its glossy, raised effects. Silk varnish, offering a smooth, soft matte finish, is generally more cost-effective and quicker to apply, making it suitable for larger print runs or budget-conscious projects. Your choice depends on balancing the desired visual impact with budget constraints, as Spot UV adds premium aesthetic value at a higher cost compared to the economical silk varnish option.

Best Uses for Spot UV

Spot UV is ideal for highlighting specific elements on printed materials, such as logos, headlines, or intricate designs, creating a striking contrast with the matte or silk background. This technique is commonly used for business cards, brochures, packaging, and invitations to add a luxurious, tactile dimension that enhances visual appeal. Spot UV's precision and glossiness make it perfect for emphasizing key branding components and attracting attention in competitive markets.

Best Uses for Silk Varnish

Silk varnish is ideal for enhancing printed materials that require a subtle, elegant finish with moderate gloss and smooth texture, such as brochures, business cards, and book covers. It provides excellent protection against fingerprints and scratches while maintaining a soft tactile feel, making it suitable for luxury packaging and high-quality marketing collateral. Silk varnish works well on both coated and uncoated papers, offering versatile application for a professional yet understated appearance.

Choosing the Right Finish for Your Project

Spot UV offers a glossy, high-contrast finish that highlights specific areas on prints, making logos or images stand out with a striking shine. Silk varnish provides a soft, matte texture with subtle sheen, enhancing durability while maintaining a tactile, elegant feel suitable for sophisticated designs. Selecting the right finish depends on desired visual impact, tactile experience, and usage requirements, with Spot UV ideal for accentuating details and Silk varnish perfect for a refined, durable surface.

spot UV vs silk varnish Infographic

libmatt.com

libmatt.com