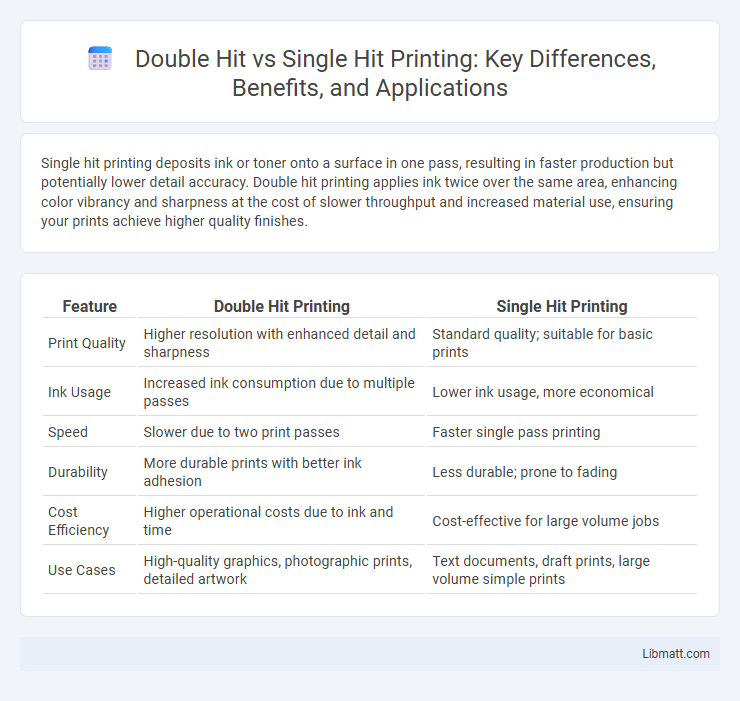

Single hit printing deposits ink or toner onto a surface in one pass, resulting in faster production but potentially lower detail accuracy. Double hit printing applies ink twice over the same area, enhancing color vibrancy and sharpness at the cost of slower throughput and increased material use, ensuring your prints achieve higher quality finishes.

Table of Comparison

| Feature | Double Hit Printing | Single Hit Printing |

|---|---|---|

| Print Quality | Higher resolution with enhanced detail and sharpness | Standard quality; suitable for basic prints |

| Ink Usage | Increased ink consumption due to multiple passes | Lower ink usage, more economical |

| Speed | Slower due to two print passes | Faster single pass printing |

| Durability | More durable prints with better ink adhesion | Less durable; prone to fading |

| Cost Efficiency | Higher operational costs due to ink and time | Cost-effective for large volume jobs |

| Use Cases | High-quality graphics, photographic prints, detailed artwork | Text documents, draft prints, large volume simple prints |

Understanding Single Hit Printing

Single hit printing deposits ink once per color pass, ensuring precise dot placement and reduced ink saturation for sharper images. This method optimizes drying time and minimizes smudging, ideal for detailed graphics and fine text. Your prints benefit from enhanced clarity and color accuracy when utilizing single hit printing technology.

What is Double Hit Printing?

Double hit printing is a specialized screen printing technique where two layers of ink are applied sequentially on the same spot to achieve a more vibrant and durable print. This method enhances color richness and increases opacity, making the design stand out on dark or challenging fabrics. Double hit printing is especially effective for bold graphics and high-detail artwork requiring sharp, vivid results.

Key Differences Between Single Hit and Double Hit Printing

Single hit printing applies ink or toner once to the substrate, resulting in faster production but potentially lower color saturation and detail. Double hit printing deposits ink or toner twice on the same area, enhancing color vibrancy, sharpness, and overall print quality, though it can reduce speed. The choice between single and double hit printing depends on the balance between desired print fidelity and production efficiency.

Print Quality Comparison: Single Hit vs Double Hit

Double hit printing delivers superior print quality by applying ink twice, enhancing color vibrancy and sharpness compared to single hit printing. Single hit printing may result in lighter colors and less detail due to a single layer of ink application, which can affect image depth. For your projects requiring crisp, vivid prints, double hit printing ensures more consistent and visually impactful results.

Ink Consumption and Efficiency

Double hit printing consumes more ink as it applies two layers per pass, resulting in richer colors but increased material usage. Single hit printing uses a single layer, optimizing ink consumption and improving process efficiency by reducing drying time and energy costs. Your choice impacts both operational expenses and environmental footprint depending on print quality requirements.

Applications Best Suited for Each Method

Double hit printing excels in applications requiring enhanced print density and color vibrancy, such as high-quality photo printing, detailed textile designs, and packaging labels where clarity and color accuracy are critical. Single hit printing is best suited for fast, economical printing needs like newspapers, flyers, or bulk promotional materials where speed and cost efficiency outweigh the need for high-resolution detail. Choosing between double hit and single hit printing depends on your project's quality demands and budget constraints, ensuring optimal results for your specific application.

Impact on Production Speed

Double hit printing significantly reduces production speed compared to single hit printing due to the necessity of printing each area twice, which doubles the time per print cycle. Single hit printing completes the job in one pass, optimizing throughput and minimizing machine downtime. Consequently, manufacturers prioritize single hit techniques for high-volume, time-sensitive production environments to maximize efficiency.

Cost Implications: Single Hit vs Double Hit

Double hit printing involves applying ink twice on the same area, leading to higher ink consumption and longer production times, which increases overall costs compared to single hit printing. Single hit printing uses less ink and speeds up the process, reducing material expenses and labor costs, making it a more cost-effective choice for large runs. Your printing budget can benefit significantly from choosing single hit methods, especially when balancing quality with expenses.

Print Durability and Longevity

Double hit printing enhances print durability by applying ink twice on the substrate, resulting in richer color saturation and improved resistance to fading compared to single hit printing. This technique increases the ink layer's thickness, providing greater protection against abrasions, UV exposure, and environmental wear. Consequently, double hit prints exhibit superior longevity, maintaining image quality over extended periods in demanding conditions.

Choosing the Right Printing Method for Your Needs

Double hit printing delivers enhanced color density and detail by passing the print head twice over the same area, making it ideal for high-resolution images and vibrant graphics. Single hit printing offers faster production speeds and lower ink usage, suitable for straightforward designs and large volume jobs. Selecting between these methods depends on balancing print quality requirements against budget and time constraints to achieve optimal results.

double hit vs single hit printing Infographic

libmatt.com

libmatt.com